Mineralized collagen/high molecule composite porous bone material and preparation method thereof

A technology of mineralizing collagen and high molecular polymers, which is applied in the field of medical materials, can solve the problems of excessive organic solvent residue, time-consuming sediment washing, and long washing time, so as to reduce the risk of solvent volatilization and toxicity, and reduce stirring and standing time, the effect of rapid and sufficient precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] (1) Use 0.5M acetic acid solution to prepare an acid solution of 0.0005g / ml type I collagen fibers;

[0148] (2) Slowly add 0.5M aqueous solution containing calcium ions dropwise to the acid solution while stirring, in an amount of 0.10 mol of calcium ions per gram of collagen, thereby forming a calcium / collagen composite solution;

[0149] (3) Add dropwise 0.5M aqueous solution containing phosphate ions while stirring in the calcium / collagen composite solution, the mol ratio of the amount of phosphate ions added to the amount of calcium ions added is Ca / P=1.5;

[0150] (4) Add dropwise 1M NaOH aqueous solution to the pH value of 8 while stirring in the solution in which phosphate ions have been added dropwise, and then stir for 16 hours to form a white suspension, leave it to stand for 18 hours, remove the supernatant, and then add Stir the purified water to the original volume, remove the supernatant after standing for 2 hours, and wash continuously for 5 times. After...

Embodiment 2 to 4

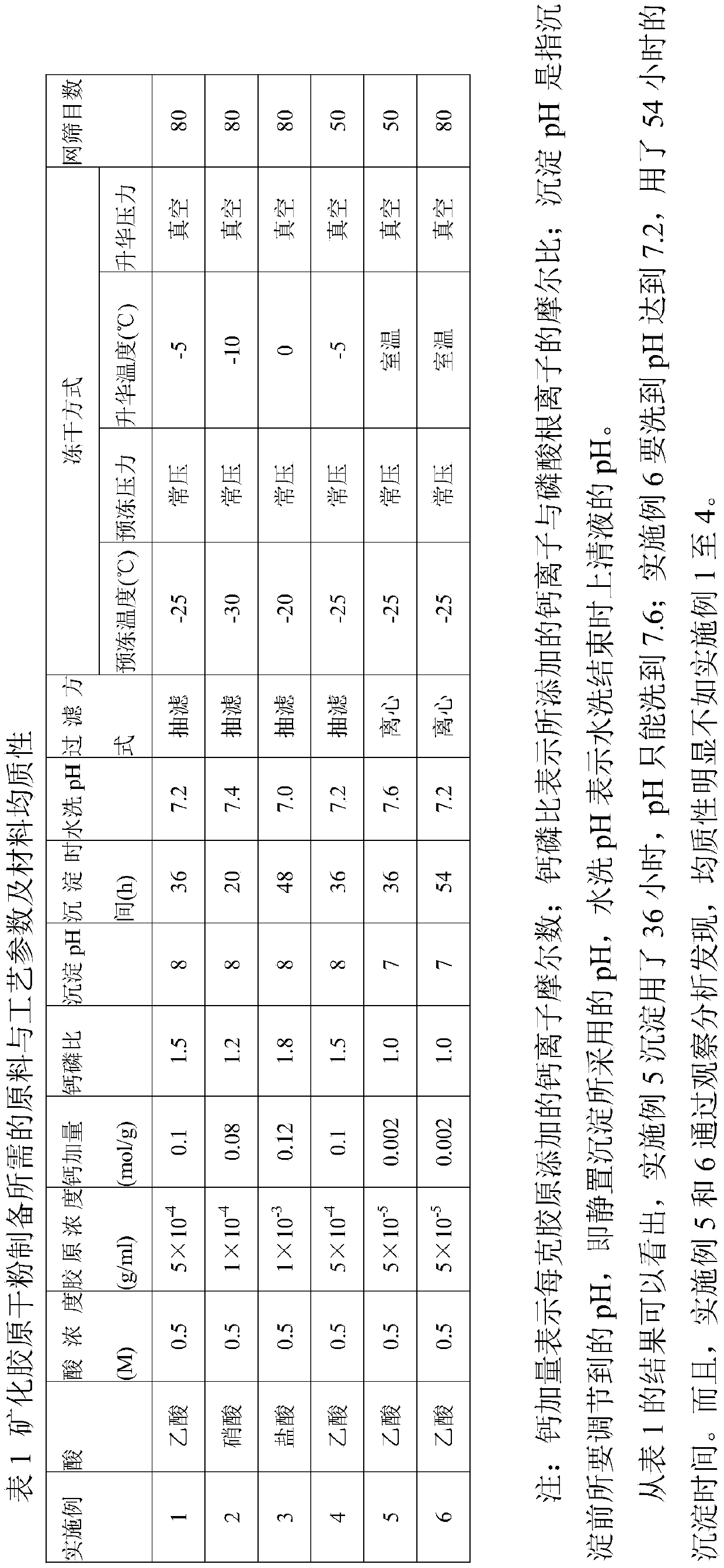

[0155] Except for the contents of Table 1 below, it was carried out in substantially the same manner as in Example 1.

Embodiment 5

[0157] Except for the contents of Table 1 below, it was carried out in substantially the same manner as in Example 1, wherein the pH was measured after a precipitation time of 36 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com