Aerobic composting waste gas treatment system and process thereof

A technology for waste gas treatment and aerobic composting, which is applied in the treatment of biological organic parts, organic fertilizers, and fertilization devices, etc., can solve the problems of insufficient consideration of the composting process, insufficient energy utilization, and no consideration of heat entrained by waste gas, so as to avoid external Environmental pollution, the effect of improving the treatment effect, and the effect of improving the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

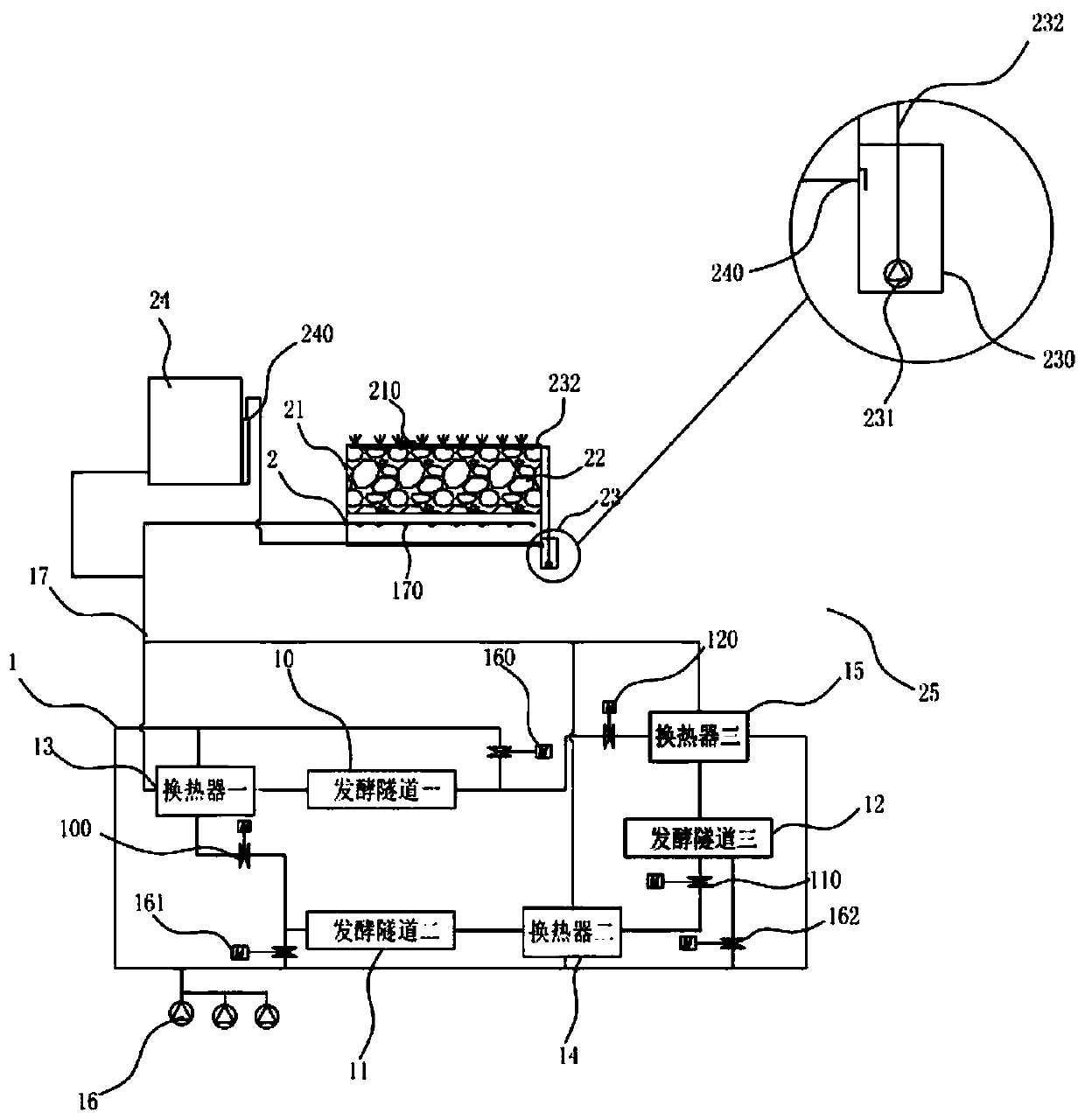

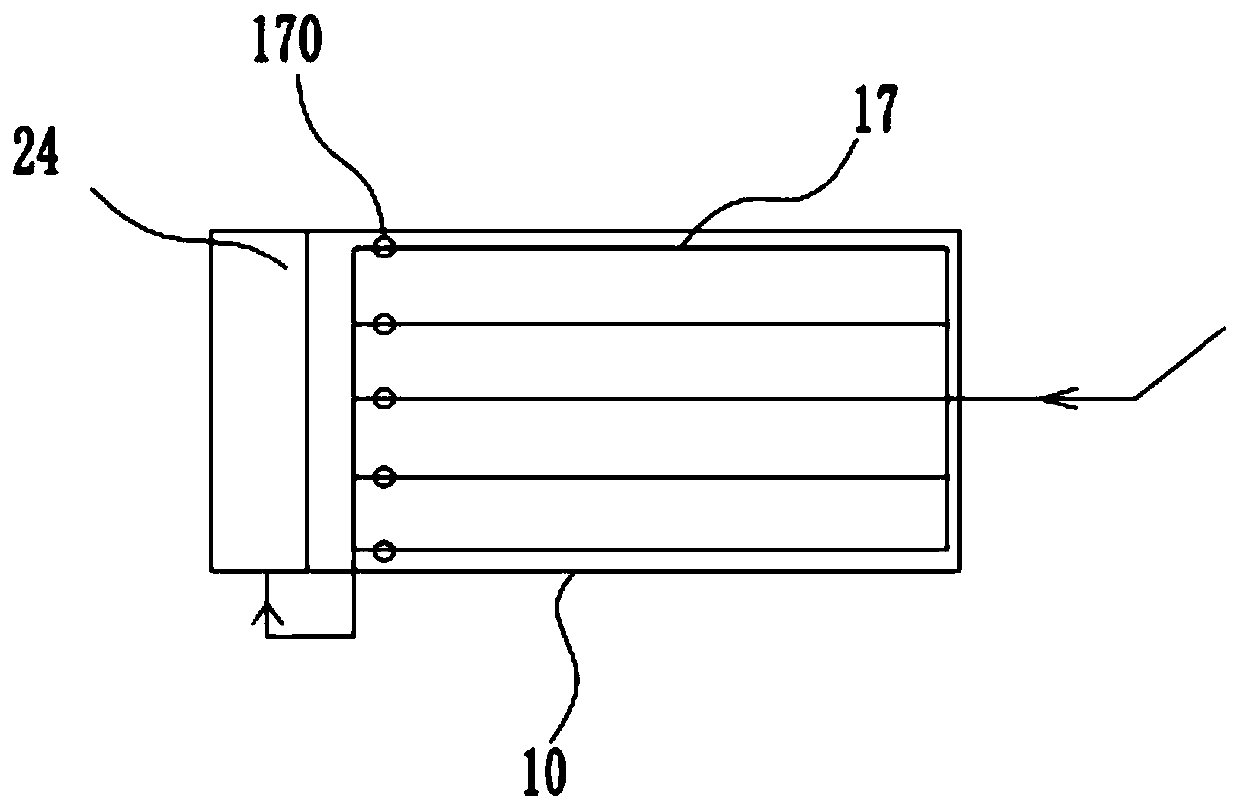

[0052] Such as figure 1 As shown, an aerobic composting waste gas treatment system mainly includes a fermentation heat exchange device 1, an underground waste gas treatment device 2, and a power supply. The fermentation heat exchange device 1 includes a fermentation tunnel 10, a fermentation tunnel 2 11, and a fermentation tunnel 3 12. , heat exchanger one 13, heat exchanger two 14, heat exchanger three 15, blower 16, the number of fermentation tunnels of the present invention can be more than 3, more than 3 fermentation tunnels constitute a closed-loop system, and two adjacent Among the two fermentation tunnels, the heat exchanged during the cooling process of one of the fermentation tunnels is used for the other heating process, the outlet end of the fermentation tunnel one 10 is connected with the entrance end of the fermentation tunnel two 11 through the heat exchanger one 13, and the connection is provided with 2 #Solenoid valve 100, the outlet end of fermentation tunnel ...

Embodiment 2

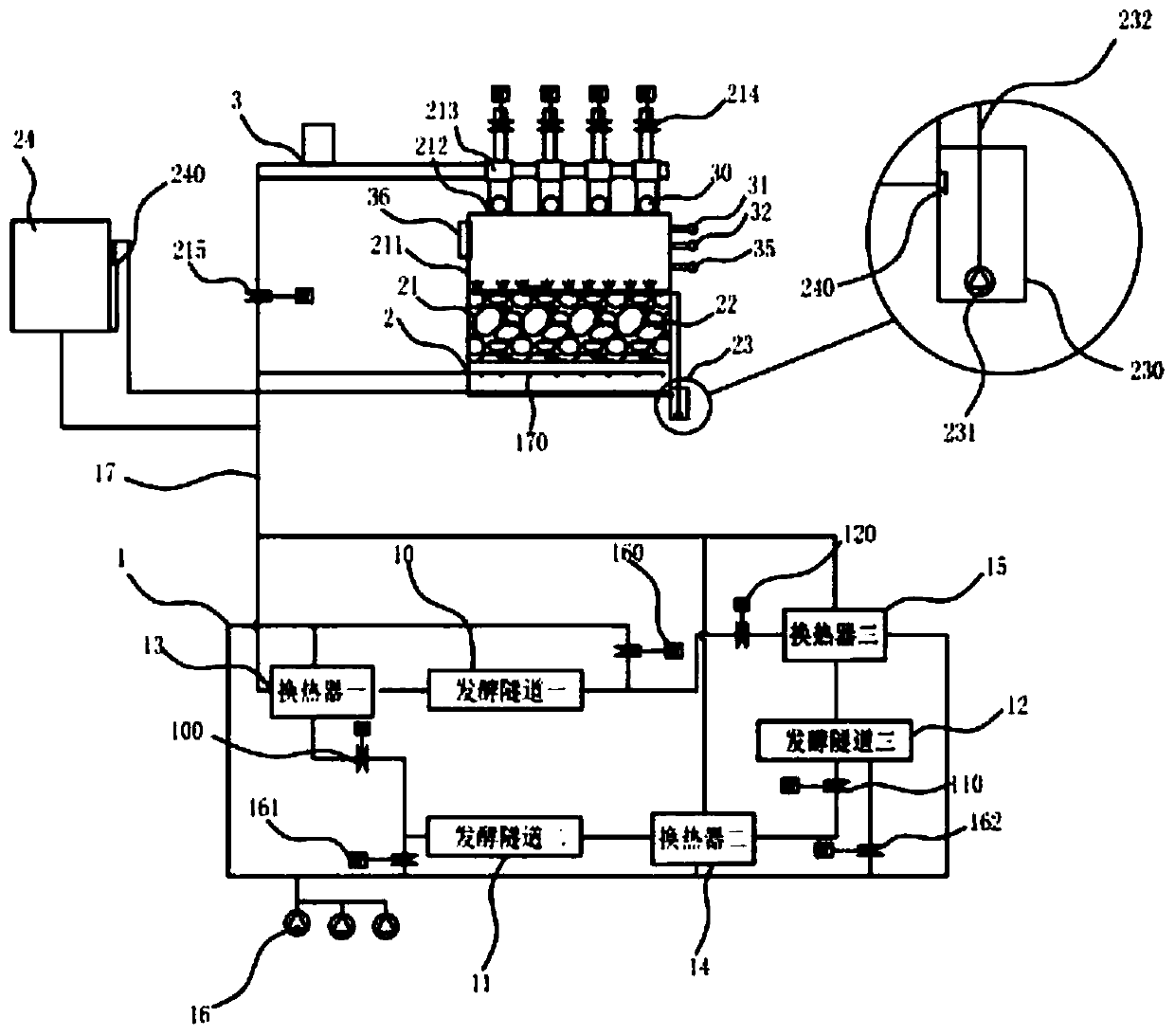

[0063] Such as image 3 As shown, an aerobic composting waste gas treatment system mainly includes a fermentation heat exchange device 1, an underground waste gas treatment device 2, an intelligent control device 3, and a power supply. The fermentation heat exchange device 1 includes a fermentation tunnel 10 and a fermentation tunnel 2 11 , fermentation tunnel three 12, heat exchanger one 13, heat exchanger two 14, heat exchanger three 15, blower 16, the outlet end of fermentation tunnel one 10 is connected with the entrance end of fermentation tunnel two 11 through heat exchanger one 13, And the junction is provided with 2# electromagnetic valve 100, the outlet end of fermentation tunnel two 11 is connected with the entrance end of fermentation tunnel three 12 through heat exchanger two 14, and the junction is provided with 3# electromagnetic valve 110, the outlet end of fermentation tunnel three 12 The outlet port is connected with the inlet port of the fermentation tunnel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com