Preparation technology applicable to hydrogen evolution cathode catalyst-oxygen-doped spherical molybdenum disulfide material

A technology of molybdenum disulfide and hydrogen evolution cathode, applied in the direction of physical/chemical process catalysts, electrodes, chemical instruments and methods, etc., can solve the problems of complex solutions, high production costs, and many equipment, so as to increase the degree of disorder and easy to operate , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

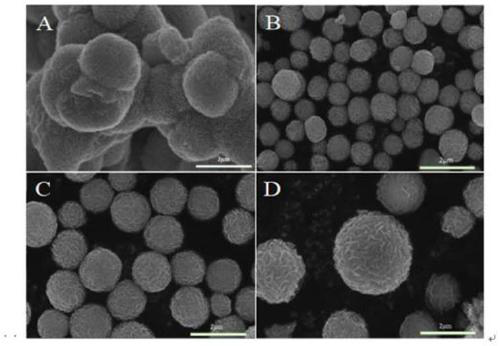

[0021] Embodiment 1: Preparation of 2H-spherical molybdenum disulfide

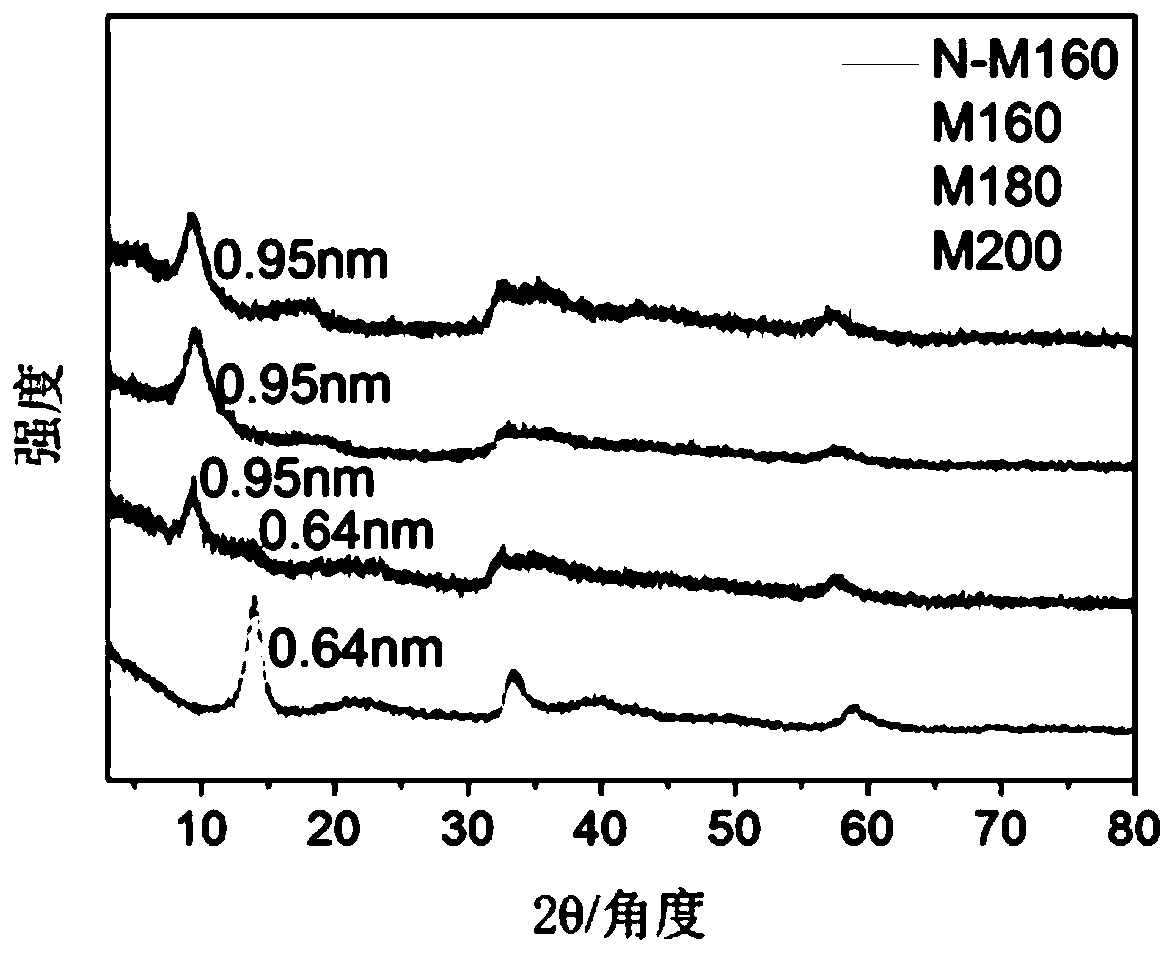

[0022] Take a certain amount of sodium molybdate, thiourea and silicon dioxide and add them to a 100mL reaction kettle in turn, stir magnetically for 30 minutes, heat at 160°C, 180°C and 200°C respectively, and cool naturally. Wash with absolute ethanol several times, and the samples are marked as M160, M180, and M200. Treatment with HF solution yielded pure 2H phase MoS2, labeled as H-M160, H-M180, H-M200, respectively. At the same time, a sample without silica was used as a comparison, and the same steps were carried out at 160°C, and only sodium molybdate and thiourea were added as raw materials. This sample was labeled H-N-M160 after treatment with hydrofluoric acid and N-M160 before treatment with hydrofluoric acid. figure 1 It is shown that the hump occurring around 2Θ = 22° can be attributed to the presence of silica. At 160°C, the (002) plane of the sample is fully extended to 0.95nm, which can ...

Embodiment 2

[0023] Embodiment 2: Preparation of oxygen-doped spherical molybdenum disulfide

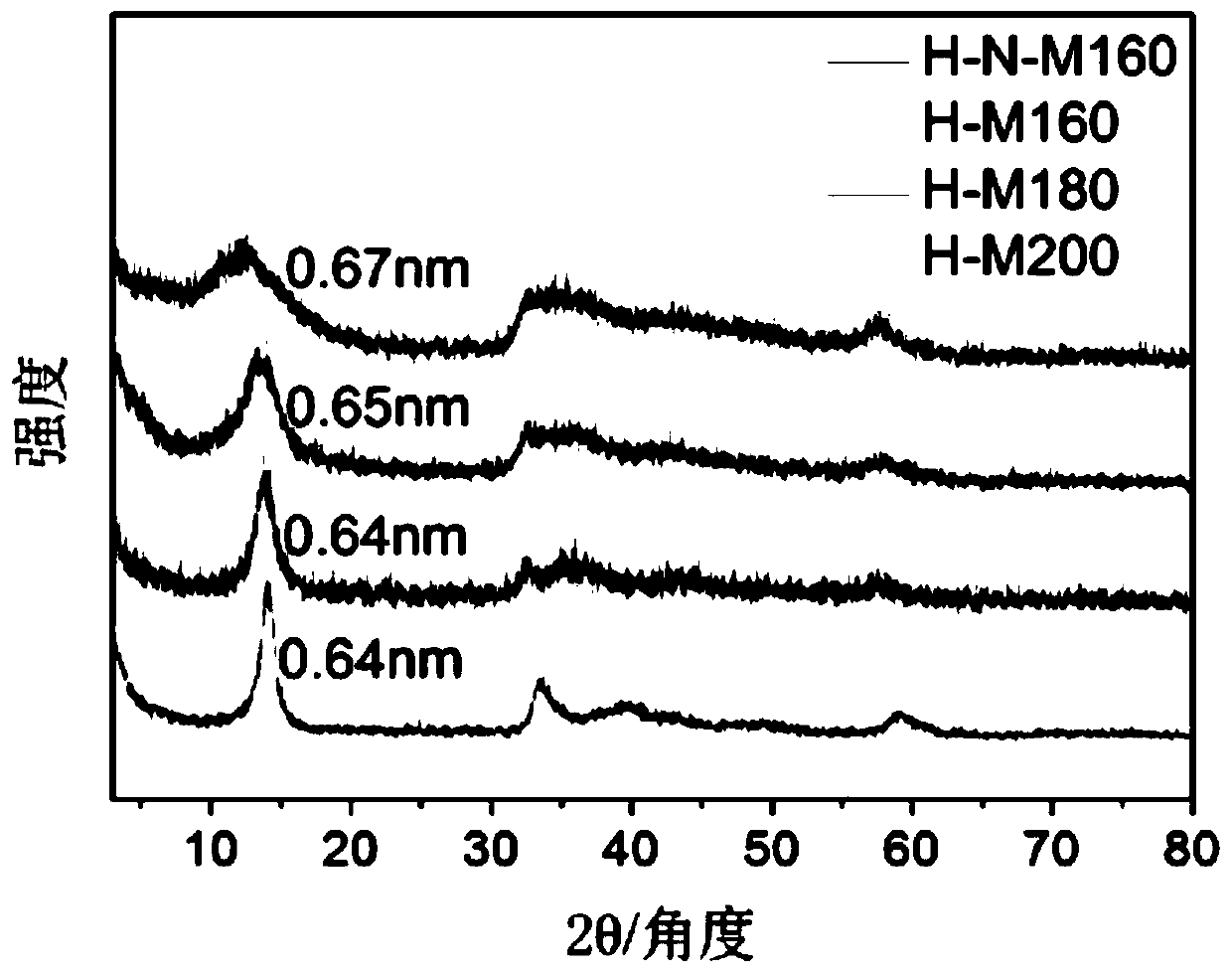

[0024]Take a certain amount of sodium molybdate, thiourea and silicon dioxide and add them to a 100mL reaction kettle in turn, stir magnetically for 30 minutes, heat at 160°C, 180°C and 200°C respectively, and cool naturally. Wash with absolute ethanol several times, and the samples are marked as M160, M180, and M200. The oxygen-doped molybdenum disulfide obtained by treating with NaOH solution is marked as N-M160, N-M180, and N-M200 respectively; at the same time, the samples without silica were used for comparison, and the same steps were carried out at 160°C. Only sodium molybdate and thiourea were added. This sample was labeled N-N-M160 after treatment with sodium hydroxide and N-M160 before treatment with sodium hydroxide. Figure 5 XRD patterns of MoS2 with different structures after NaOH treatment are shown. In N-N-M160, N-M160, and N-M180 samples, the interlayer spacing at 2θ=8.9° is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com