Device of compound eye metal structure and method thereof

A metal structure and metal technology, applied in the field of compound eye metal structure devices, can solve the problems of insufficient market applicable function range, low product yield, high energy consumption, etc., and achieve the effects of light weight, low density and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

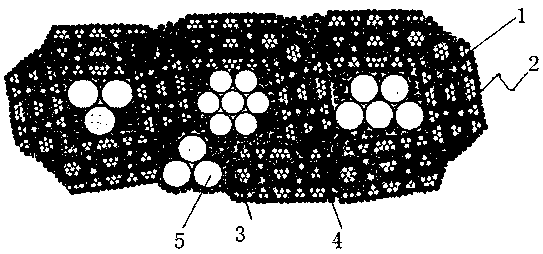

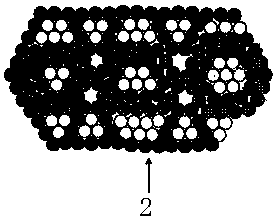

[0018] See Figure 1 to Figure 4 These four figures show the overall appearance of an embodiment of a compound eye metal structure device proposed by the present invention. The device includes a solid vacuum sphere 1 and a layer of sphere wall 2 wrapped on the outside of the solid vacuum sphere 1, and a solid metal 3 and a solid non-metal 4 are installed in the solid vacuum sphere 1 and the sphere wall 2. In addition, an inert gas 5 is provided in the solid metal 3 and the solid non-metal 4.

[0019] The solid vacuum sphere 1 and the sphere wall 2 are all provided with solid metal 3, solid non-metal 4, and inert gas 5 three parts, wherein the inert gas 5 uses nitrogen, argon, and the solid non-metal 4 can be used Silica, carbon, and the solid metal 3 can be iron, copper, aluminum, molybdenum, chromium, nickel, titanium, podium, cobalt, zirconium, rhenium, and the molecular diameter of the inert gas 5 is 0.2-0.5 nm.

[0020] The method of manufacturing the above-mentioned metal st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com