High-performance functionalized alloy modified polypropylene corrugated pipe special-use material and preparation method thereof

A technology of polypropylene and chemical alloys, which is applied in the field of high-performance functional alloy modified polypropylene corrugated pipe special materials and its preparation, can solve the problems of inability to achieve flame retardancy, poor low-temperature performance, and high processing costs, and achieve surface gloss Good, good anti-crack performance, small thermal shrinkage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-performance functional alloy modified polypropylene bellows special material is composed of: 65 parts of homopolypropylene powder, 15 parts of block copolymerized polypropylene powder, 10 parts of filler, 5 parts of compatibilizing and toughening agent, fluidity 2.5 parts of modifier, 2 parts of flame retardant, 0.3 part of antioxidant, 0.2 part of ultraviolet absorber.

[0034] The preparation method is carried out according to the following steps:

[0035] (1) Add 8 kg of hollow glass microspheres, 2 kg of nano-calcium carbonate and 1 wt% silane coupling agent KH560 into the high mixer, keep the speed at 2000 rpm, and stir at high speed for 20 minutes to obtain the filler described in the present invention ;

[0036](2) 5 kg polypropylene (PP), 0.5 wt% dicumyl peroxide (DCP), 3 wt% maleic anhydride (MAH), and 5 wt% siloxane KH580 were added to the internal mixer together, Banburying at 190°C for 8 min at a rotating speed of 30 rpm to obtain the compatibilizin...

Embodiment 2

[0042] A high-performance functional alloy modified polypropylene bellows special material is composed of: 70 parts of homopolypropylene powder, 10 parts of block copolymerized polypropylene powder, 8 parts of filler, 7 parts of compatibilizing and toughening agent, fluidity 2.5 parts of modifier, 2.2 parts of flame retardant, 0.2 part of antioxidant, 0.1 part of ultraviolet absorber.

[0043] The preparation method is carried out according to the following steps:

[0044] (1) Add 5 kg of hollow glass microspheres, 3 kg of nano-calcium carbonate and 1 wt% of silane coupling agent KH550 into the high mixer, keep the speed at 2000 rpm, and stir at high speed for 20 minutes to obtain the filler described in the present invention ;

[0045] (2) Add 5 kg polypropylene (PP), 0.8 wt% dicumyl peroxide (DCP), 5 wt% maleic anhydride (MAH), and 8 wt% vinyltriethoxysilane to the banburying mixer In the machine, at 190 ℃, banburying 8 min under the condition of rotating speed 30 rpm, obt...

Embodiment 3

[0050] (1) Add 5 kg polypropylene (PP), 0.8 wt% dicumyl peroxide (DCP), 5 wt% maleic anhydride (MAH), and 8 wt% vinyltriethoxysilane to the banburying mixer In the machine, at 190 ℃, banburying 8 min under the condition of rotating speed 30 rpm, obtain the compatibilizing and toughening agent of the present invention;

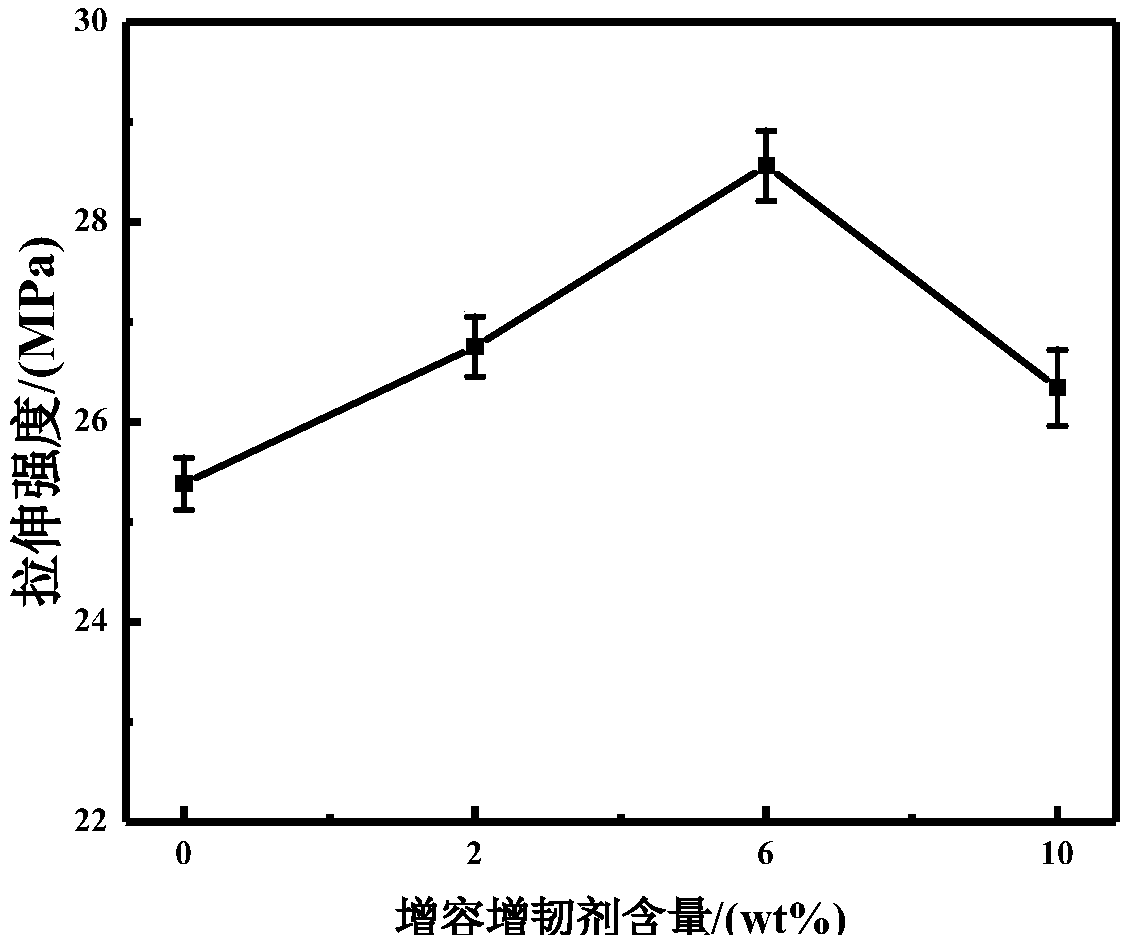

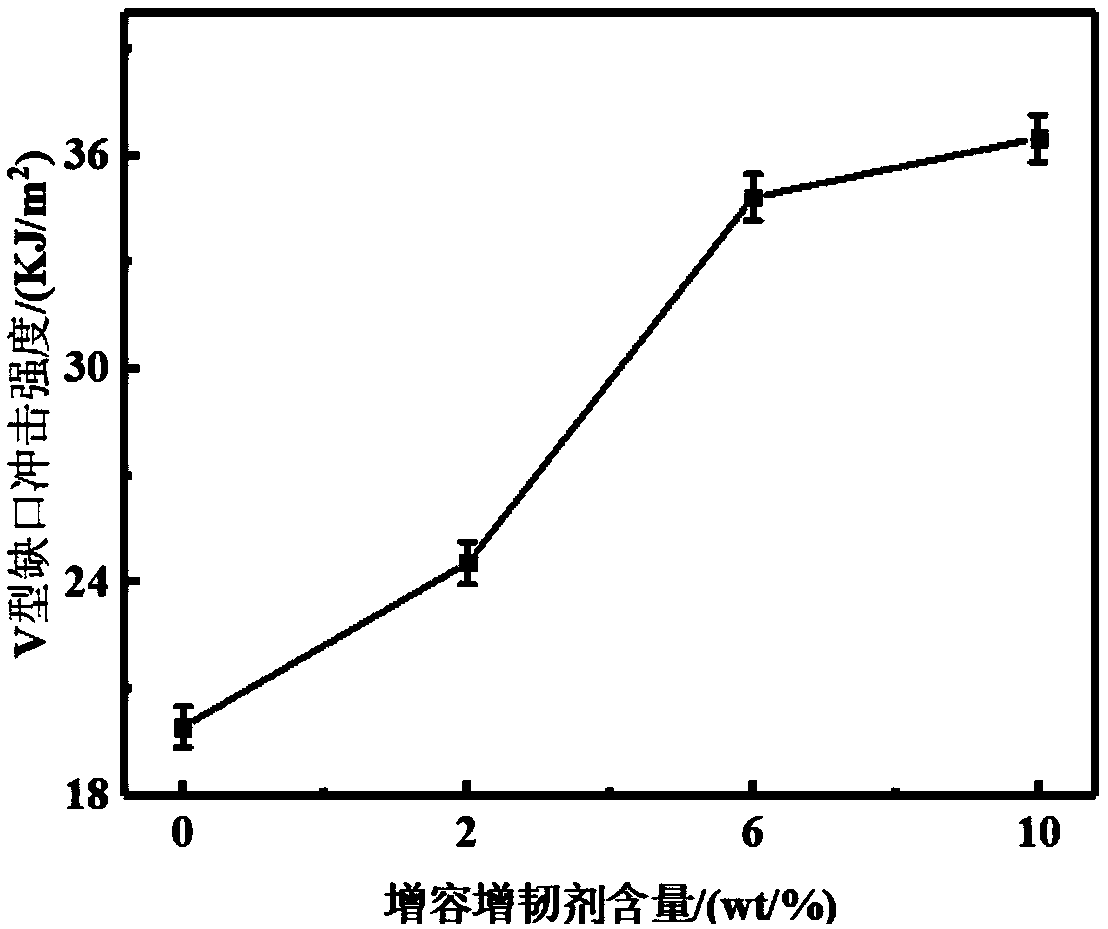

[0051] (2) Mix 2.0 kg of homopolypropylene and 8.0 kg of block copolymerized polypropylene with the above-mentioned compatibilizing and toughening agent. Melt granulation is carried out in the extruder, the barrel temperature is 130 °C, 145 °C, 155 °C, 170 °C, 180 °C, 185 °C, 195 °C, 205 °C, 180 °C, 170 °C, the screw speed is 160r / min, The feeding speed is 16 r / min. The masterbatch is injected, and the temperature of the injection molding machine is 200 °C, 200 °C, and 190 °C. The samples obtained by injection molding were subjected to tensile (GB / T1040.2-2006) and impact (GB / T1943-2008) performance tests, and the results are shown in figure 1 and figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com