Normal-temperature weak-alkali geopolymer excited cement soil and preparation process thereof

A geopolymer cement and alkali-activated technology, which is applied in cement production and other fields, can solve the problems that the properties of cement and soil need to be further improved, and achieve the effects of suitable setting time, good toughness and crack resistance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

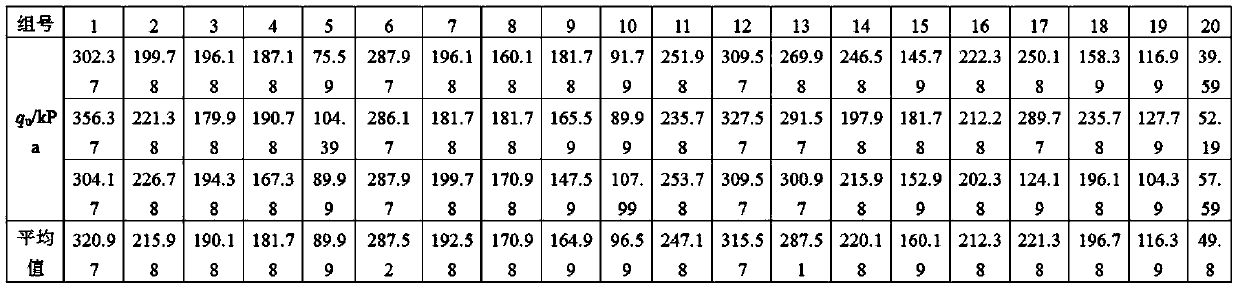

[0022] Embodiment 1 Unconfined compressive strength test

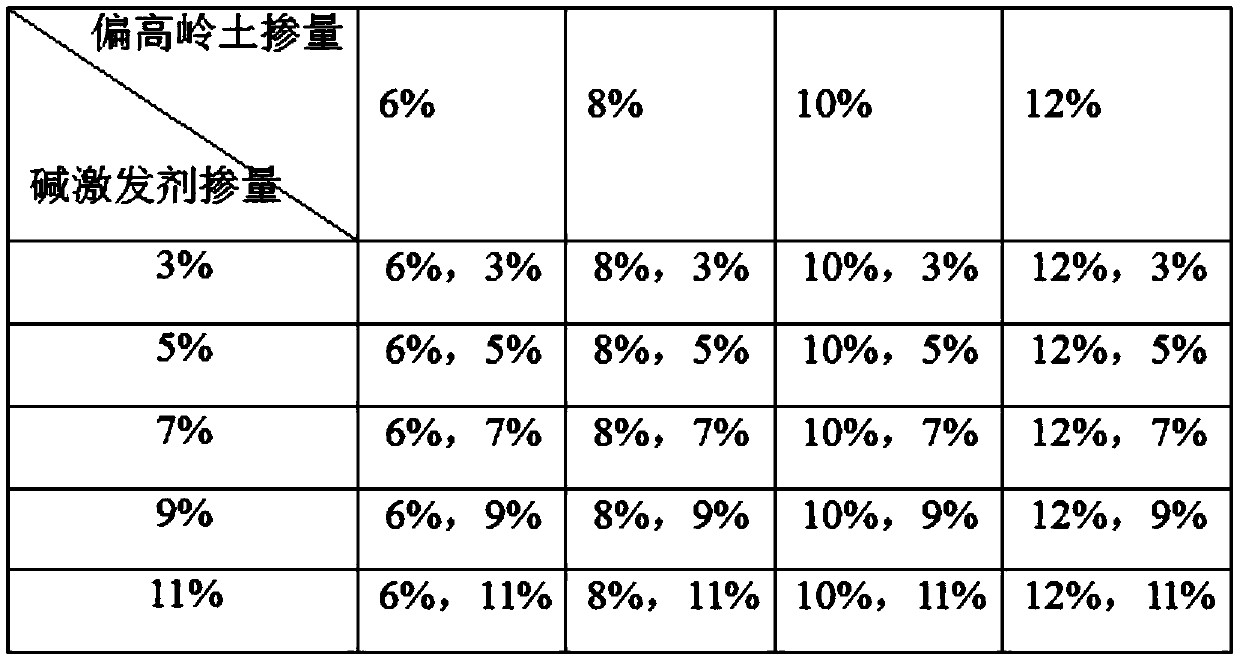

[0023] A normal temperature weak alkali geopolymer stimulated cement soil, including alkali activated cementitious material and clay, the alkali activated cementitious material comprises an active agent and an active agent, with clay as a reference, the dosage of the active agent is 6%-12 %, the dosage of the activator is 3%-11%. The activator is metakaolin, and the activator is uniformly dry mixed with lime and baking soda.

[0024] Among them, the dosage of metakaolin is 6%, 8%, 10%, 12%, the dosage of activator is 3%, 5%, 7%, 9%, 11%, and the particle size of the selected clay is not more than 2mm. Experiment Table 1 is shown below.

[0025] Table 1 Unconfined compressive strength test table of cement soil stimulated by metakaolin base polymer

[0026]

[0027] Specific steps:

[0028] 1) Weigh each component of the alkali-activated gelling material and the clay according to the designed ratio, and wait for us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com