Ultra-wideband low-profile conformal antenna

A conformal antenna, low-profile technology, applied in the direction of antennas, antenna parts, antenna supports/mounting devices, etc., can solve problems such as beam shape distortion, affect system use, and cannot meet the requirements of antenna frequency bandwidth, etc., to achieve directional Figure stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

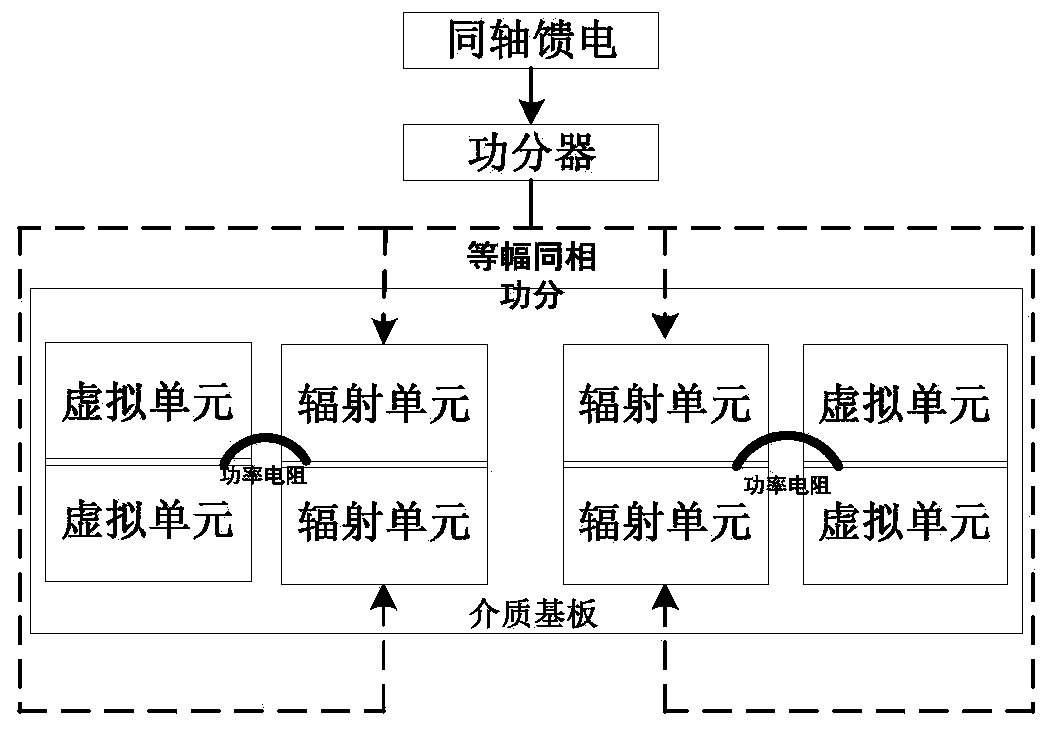

[0037] This embodiment proposes an ultra-wideband low-profile conformal antenna, such as image 3 As shown, the conformal antenna is composed of radiating elements and virtual elements. Both the radiating unit and the dummy unit are printed on a thin dielectric substrate, and the radiating units and the dummy units are connected by tight coupling, and at the end of the radiating unit, a power resistor is used to connect to the dummy unit. Finally, a power divider is used to combine the ports of multiple radiating elements with equal amplitude and in-phase to improve the gain of the conformal antenna and reduce the influence of the external environment on the direction of the conformal antenna. Wherein, the structure of the radiation unit is the same as that of the dummy unit, which can be formed in the form of microstrip antenna or dipole antenna, etc., and the dielectric substrate can be FR-4 epoxy resin board.

[0038] Due to the softness of the dielectric substrate, in ord...

Embodiment 2

[0040] This embodiment is on the basis of embodiment 1:

[0041] The antenna of this embodiment is an ultra-wideband low-profile conformal receiving antenna with a working frequency band of 0.1GHz to 0.8GHz. The simulation model is as follows Figure 5 shown.

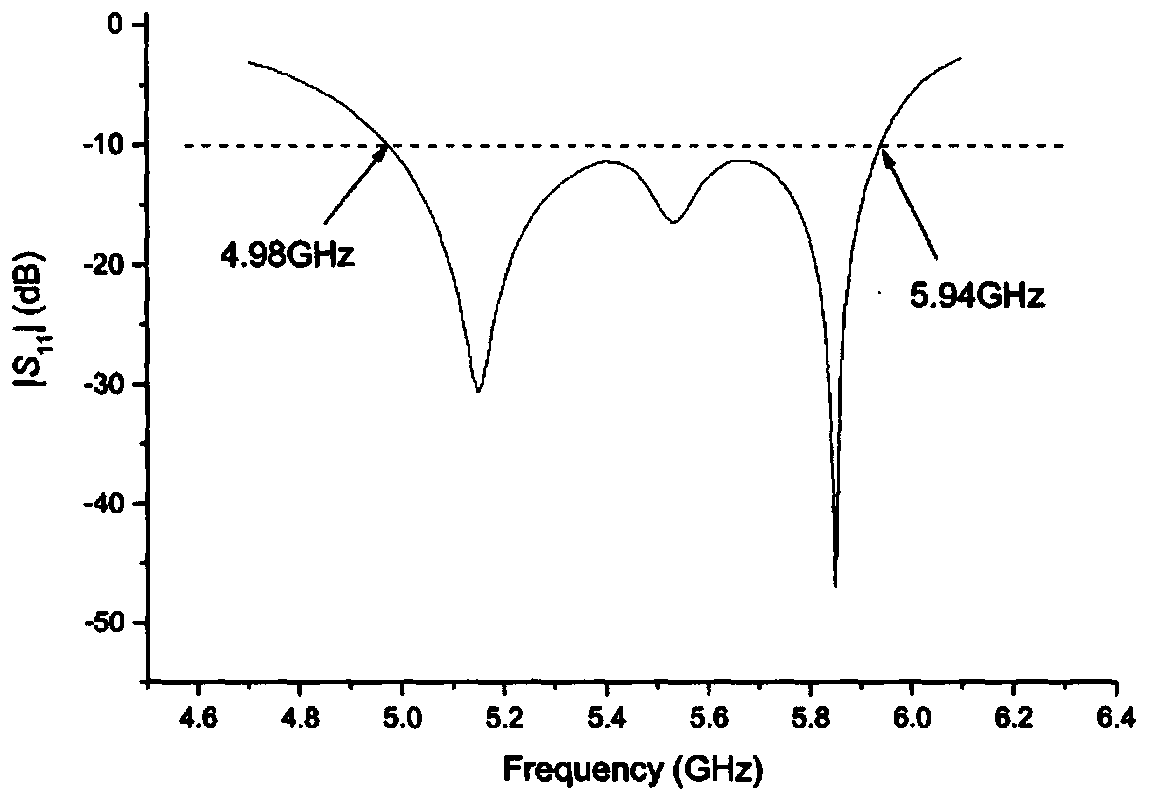

[0042] The simulation results of the standing wave coefficient are as follows: Figure 6 As shown, the bandwidth of the antenna with a Voltage Standing Wave Ratio (Voltage Standing WaveRatio, VSWR) not greater than 2.0 is 0.1 GHz-0.8 GHz, and the relative bandwidth reaches an octave of 8 times.

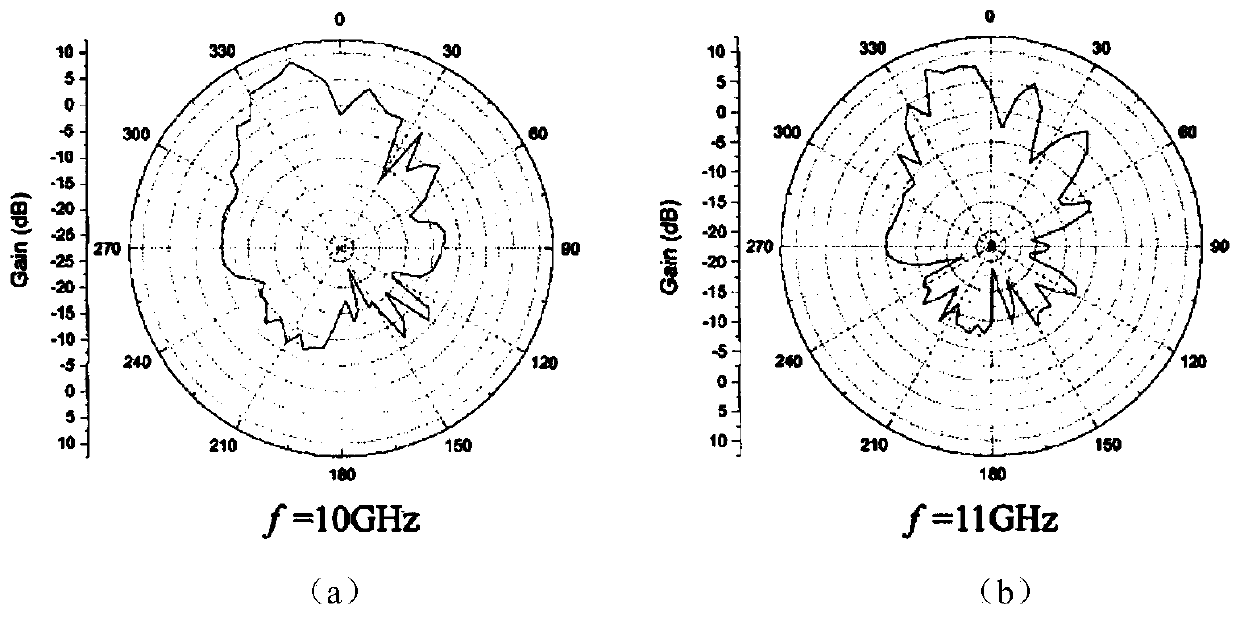

[0043] The simulation results of the direction diagram are as follows: Figure 7 As shown, (a) and (b) respectively represent the simulation results of the pattern of the azimuth plane and the elevation plane, and different curves represent the pattern of different frequencies. From the simulation results, it can be seen that the pattern of the antenna is relatively smooth in the ultra-wide frequency band of 0.1GHz to 0.8GHz...

Embodiment 3

[0045] This embodiment is on the basis of embodiment 2:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com