Chemical bath method for depositing electrochromism membrane

An electrochromic and thin-film technology, applied in the direction of coating, etc., can solve the problems of unusable and uneven electrochromic thin films, and achieve the effect of low degree of hydrolysis and uniform and controllable thin film deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

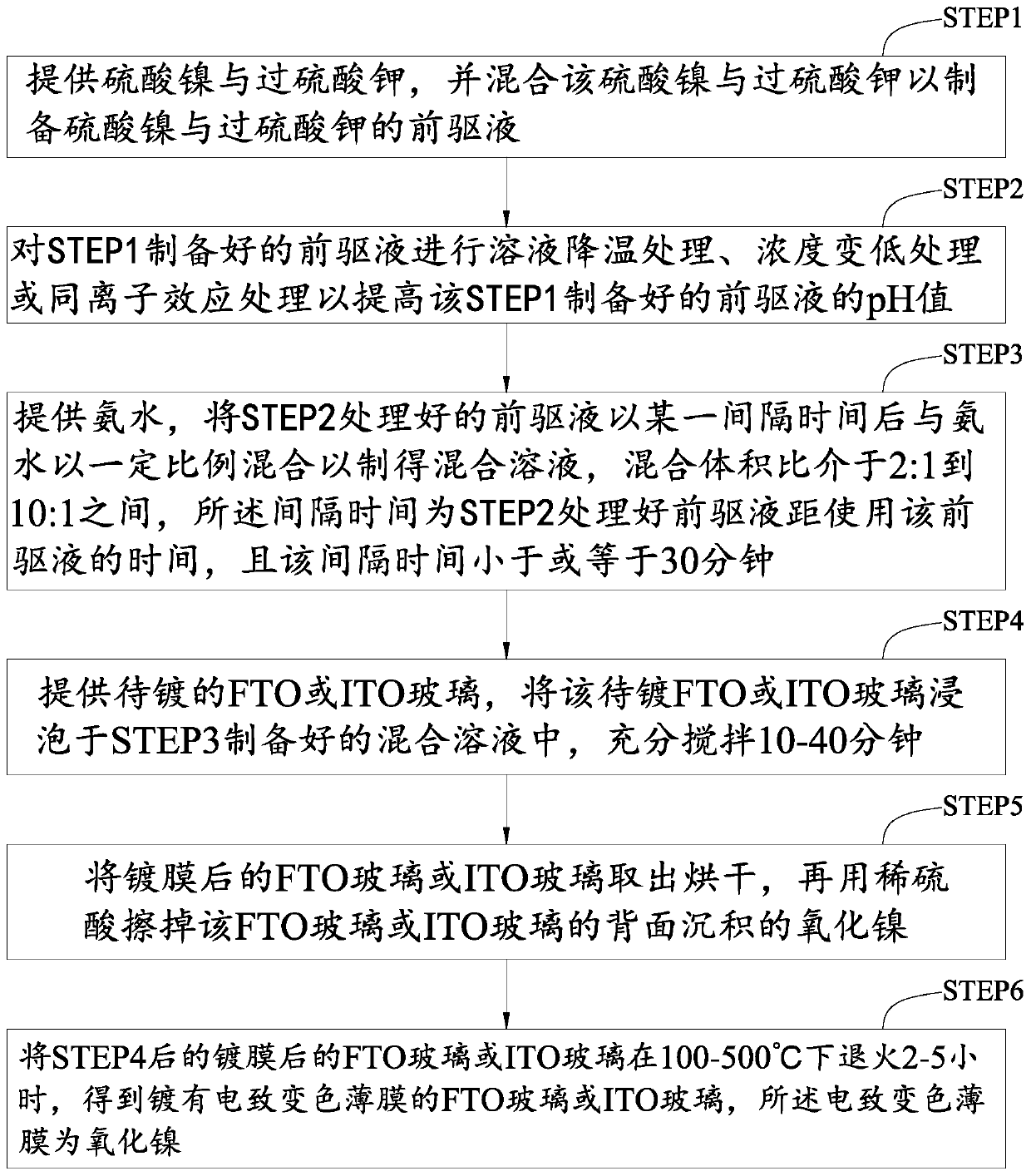

[0028] Such as figure 1 As shown, it is a flow chart of the chemical bath method for depositing an electrochromic thin film provided by the present invention. The chemical bath method of the deposition electrochromic thin film comprises the steps:

[0029] STEP1: provide nickel sulfate and potassium persulfate, and mix the nickel sulfate and potassium persulfate to prepare the precursor solution of nickel sulfate and potassium persulfate;

[0030] The nickel sulfate is an inorganic substance, which is the source of metal nickel ions, and can dissociate nickel ions and sulfate ions during the reaction process. The potassium persulfate is also an inorganic compound and is a white crystal. The persulfate in the potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com