Preparation method of titanium dioxide nanotube array sensitized by cadmium sulfide nanoparticles

A nanotube array, nanoparticle technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of complex process, reduced photoelectric conversion efficiency, high toxicity, etc., to achieve simple operation and improve photoelectric conversion efficiency. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

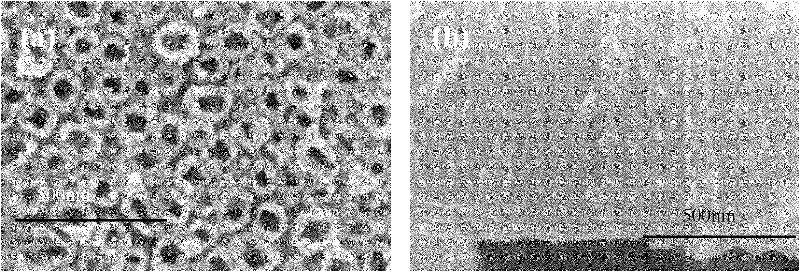

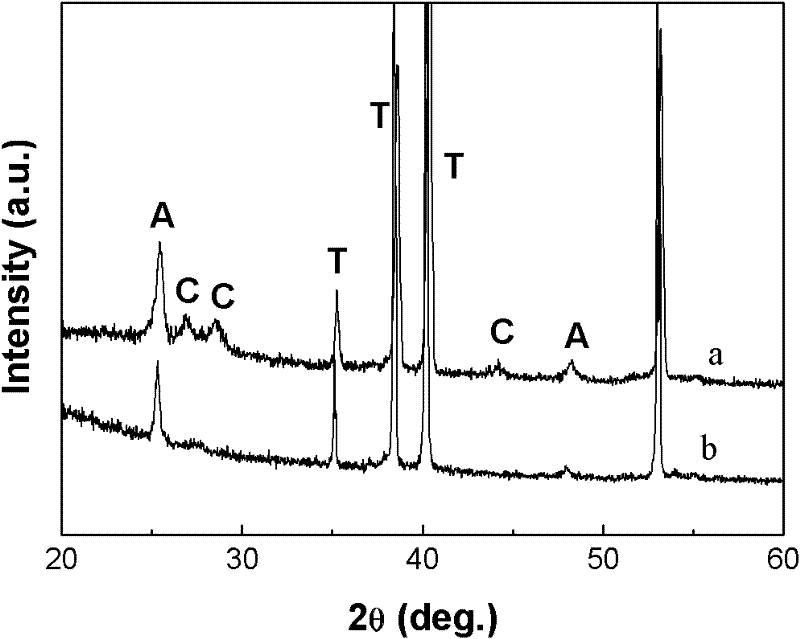

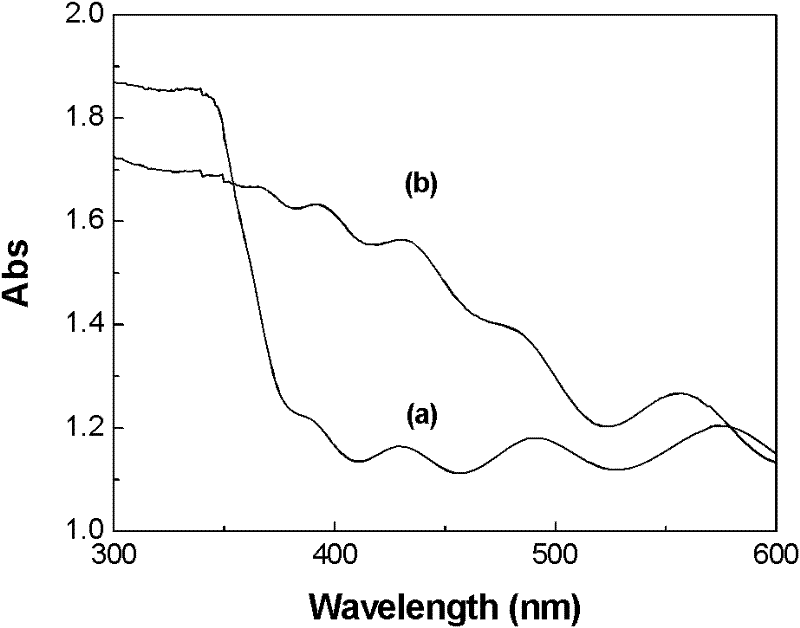

[0020] (1) The base material is a pure titanium foil with a thickness of 0.1mm, which is cleaned with acetone, ethanol and three times of ultrasonic cleaning in water, and is allowed to dry for later use. Formulated to contain 0.5wt% NH 4 F glycerol and water (volume ratio 2:1) mixed solution, platinum is used as the counter electrode at room temperature, electrochemical anodization is carried out at 20V voltage for 30 minutes, and then the film is heat-treated at 450 ℃ for 2 hours, that is, in titanium Ordered anatase TiO on the foil surface 2 Nanotube array film layer.

[0021] (2) The method of galvanostatic electrodeposition is used to prepare CdS nanoparticles sensitized TiO 2 Nanotube array. Put the sample prepared in step (1) into a DMSO electrolyte with an S concentration of 0.03M and a Cd / S concentration ratio of 1:4, with a platinum electrode as the counter electrode, and a current density of -0.75mA / cm 2 Deposited for 5 minutes at room temperature under the conditions ...

Embodiment 2

[0023] (1)TiO 2 The preparation of the nanotube array film layer is the same as in Example 1.

[0024] (2) Put the sample prepared in step 1 into a DMSO electrolyte with an S concentration of 0.01M and a Cd / S concentration ratio of 1:4, with a platinum electrode as the counter electrode, and a current density of -0.25mA / cm 2 Deposition for 10 minutes at room temperature under the conditions of, the CdS nanoparticles sensitized TiO 2 Nanotube array.

Embodiment 3

[0026] (1)TiO 2 The preparation of the nanotube array film layer is the same as in Example 1.

[0027] (2) Put the sample prepared in step 1 into a DMSO electrolyte with an S concentration of 0.01M and a Cd / S concentration ratio of 1:2, with a platinum electrode as the counter electrode, and a current density of -0.25mA / cm 2 Deposited for 5 minutes at room temperature under the conditions of, the CdS nanoparticles sensitized TiO 2 Nanotube array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com