Preparation method of modified graphene oxide polyurethane coating layer material

A graphene polyurethane and oxide stone technology, which is applied in the field of preparation of modified graphene oxide polyurethane coating materials, can solve the problems of poor high temperature performance of polyurethane, increased residue rate, filter blockage, etc., and achieves improved ablation resistance. performance, reducing residue rate, improving Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

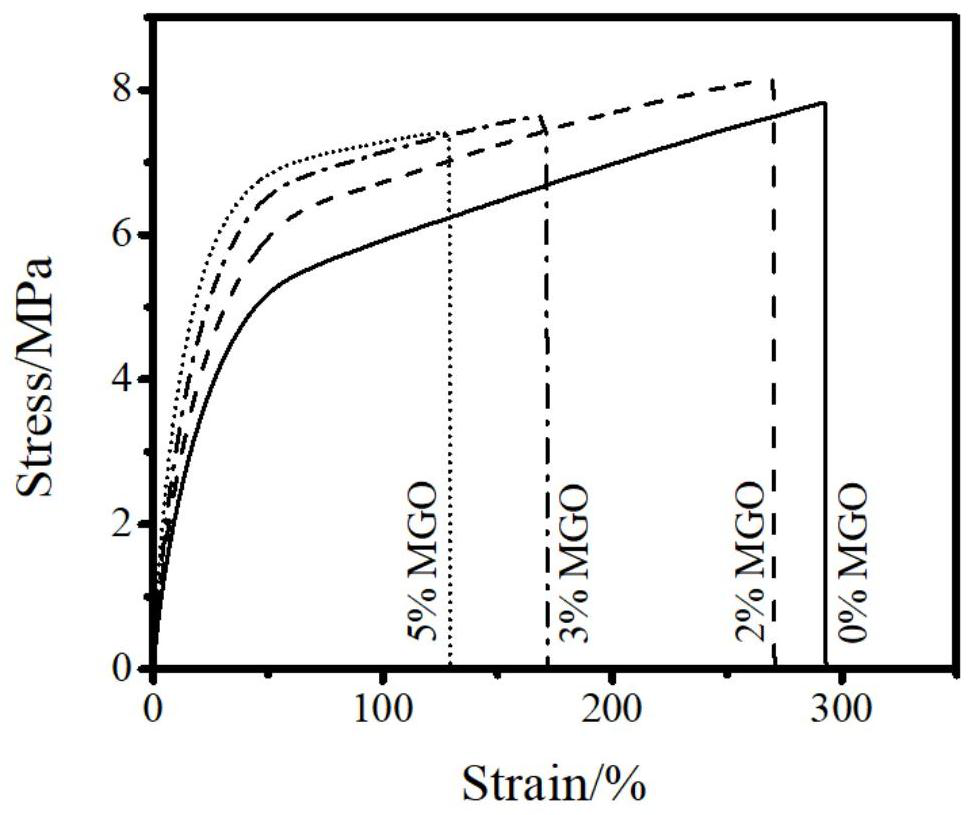

[0024] Embodiment 1 prepares the polyurethane coating layer of MGO content 2%

[0025] (1) Weigh 2gA component and 84mgMGO powder, and mix;

[0026] (2) Add an appropriate amount of butyl acetate, stir evenly and then ultrasonically disperse for 30 minutes;

[0027] (3) The mixed solution was incubated at 50°C for 48h to remove butyl acetate;

[0028] (4) Add 2.2g of component B and 0.42g of butyl acetate, and stir evenly;

[0029] (5) Keep the above mixed solution at a vacuum of 0.098MPa for 5min;

[0030] (6) Pour into a mold and cure at 45° C. for 24 hours to prepare a sample.

Embodiment 2

[0031] Embodiment 2 prepares the polyurethane coating layer of MGO content 3%

[0032] (1) Weigh 2gA component and 126mgMGO powder, and mix;

[0033] (2) Add an appropriate amount of butyl acetate, stir evenly and then ultrasonically disperse for 30 minutes;

[0034] (3) The mixed solution was incubated at 50°C for 48h to remove butyl acetate;

[0035] (4) Add 2.2g of component B and 0.42g of butyl acetate, and stir evenly;

[0036] (5) Keep the above mixed solution at a vacuum of 0.098MPa for 5min;

[0037] (6) Pour into a mold and cure at 45° C. for 24 hours to prepare a sample.

Embodiment 3

[0038] Embodiment 3 prepares the polyurethane cladding layer of MGO content 5%

[0039] (1) Weigh 2gA component and 0.21gMGO powder, and mix;

[0040] (2) Add an appropriate amount of butyl acetate, stir evenly and then ultrasonically disperse for 30 minutes;

[0041] (3) The mixed solution was incubated at 50°C for 48h to remove butyl acetate;

[0042] (4) Add 2.2g of component B and 0.42g of butyl acetate, and stir evenly;

[0043] (5) Keep the above mixed solution at a vacuum of 0.098MPa for 5min;

[0044] (6) Pour into a mold and cure at 45° C. for 24 hours to prepare a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com