Non-yellowing polyurethane memory cotton and preparation method thereof

A technology of polyurethane and memory foam, which is applied in the field of non-yellowing polyurethane memory foam and its preparation, can solve the problems of no related research on the preparation of non-yellowing memory foam, save manpower and equipment costs, improve quality stability, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

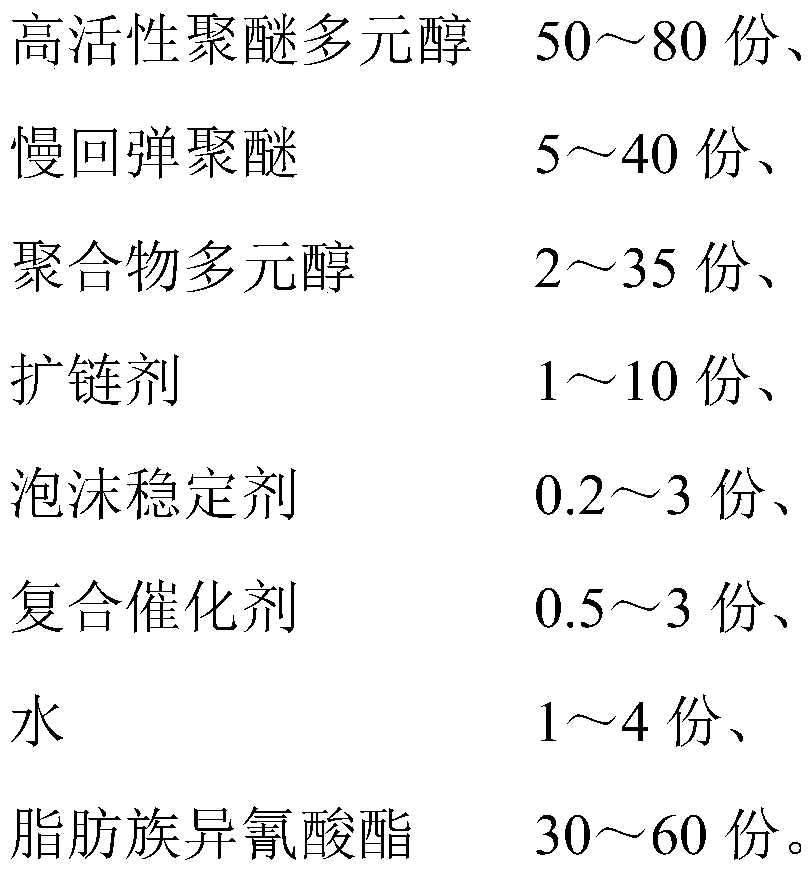

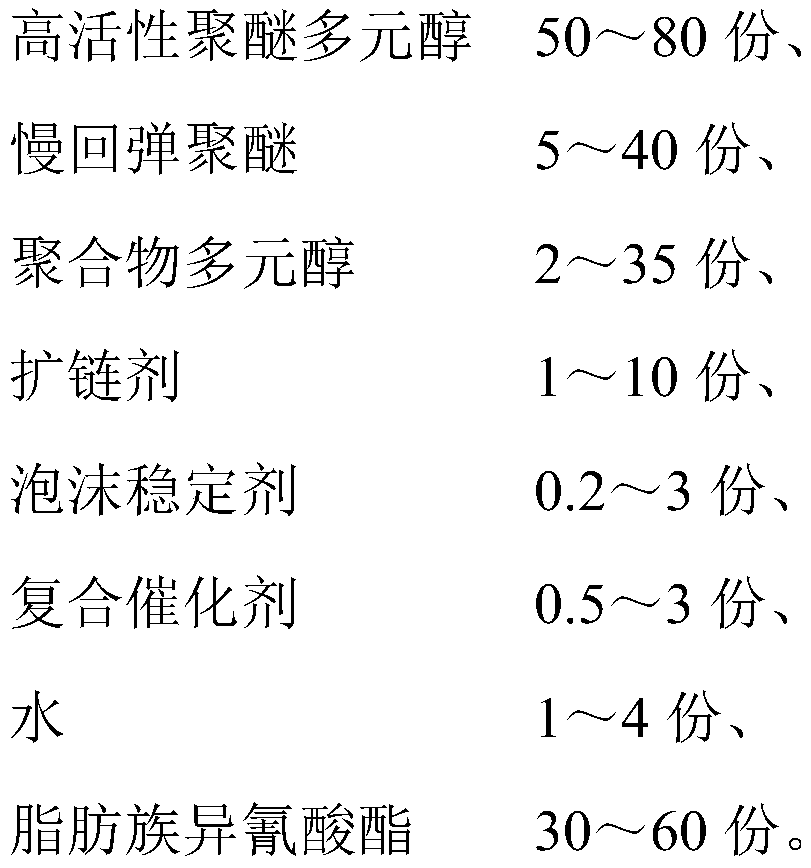

[0032] A kind of non-yellowing polyurethane memory cotton is made of the raw materials comprising the following parts by weight:

[0033]

[0034] The non-yellowing polyurethane memory foam in this embodiment is composed of selected raw materials, and the content of each raw material is optimized, and an appropriate proportion of high-activity polyether polyol, slow rebound polyether, polymer polyol, chain extender, Foam stabilizer, composite catalyst, water and aliphatic isocyanate not only give full play to their respective advantages, but also complement each other and promote each other to improve the quality stability of the product. The prepared non-yellowing polyurethane memory foam has high light fastness, durability Phenol has good yellowing performance, high smoke resistance level, long slow rebound recovery time, and low ball rebound rate.

[0035] This embodiment selects high activity polyether polyol, slow resilience polyether, polymer polyol as polyol with app...

Embodiment 2 to 4

[0054] The raw material formula of embodiment 2 to 4 is as shown in table 1 and table 2 below:

[0055] Table 1

[0056] Polyol 1 Functionality 3, molecular weight 3800, hydroxyl value 44mg KaOH / g, ethylene oxide 70%, primary hydroxyl 80% Polyol 2 Functionality 4, molecular weight 5300, hydroxyl value 42mg KaOH / g, ethylene oxide 75%, primary hydroxyl 75% Polyol 3 Starting from glycerol, functionality 3, molecular weight 700, hydroxyl value 240mg KaOH / g Polyol 4 Starting from glycerol, functionality 3, molecular weight 550, hydroxyl value 306mg KaOH / g Polyol 5 Styrene acrylonitrile graft polyether, hydroxyl value 26, solid content 43%, molecular weight 4000 Polyol 6 Styrene acrylonitrile grafted polyether, hydroxyl value 22, solid content 45%, molecular weight 5000

[0057] Note: "polyol 1 and polyol 2" in Table 1 are any one of the high-activity polyether polyols described in the present invention; Any one of the polyethers; "p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com