Polyaniline/barium titanate composite material, preparation method and application

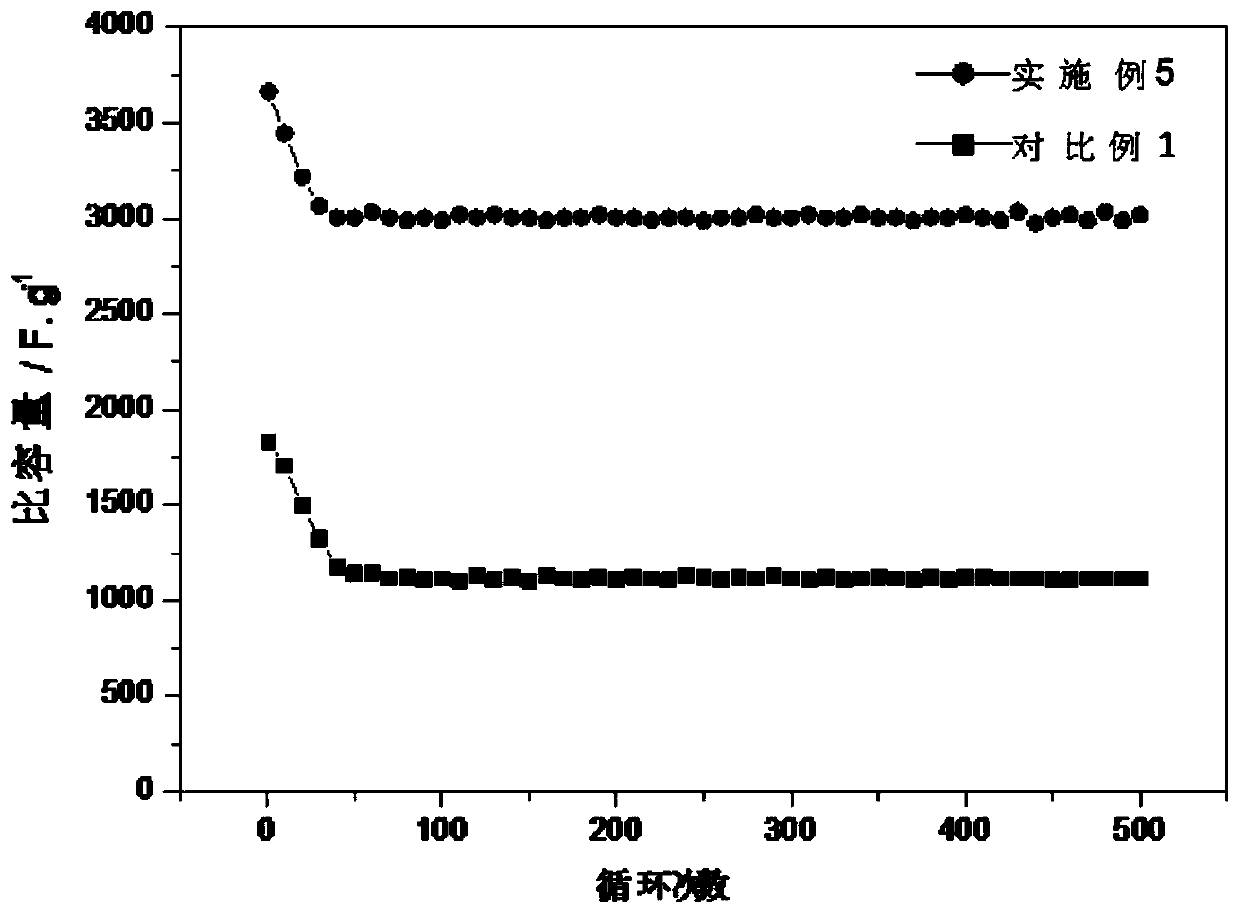

A composite material, barium titanate technology, applied in the field of polyaniline/barium titanate composite material and its preparation, can solve problems such as difficulty in meeting the practical application requirements of supercapacitors, achieve short experimental period, improve specific capacitance, and good cycle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

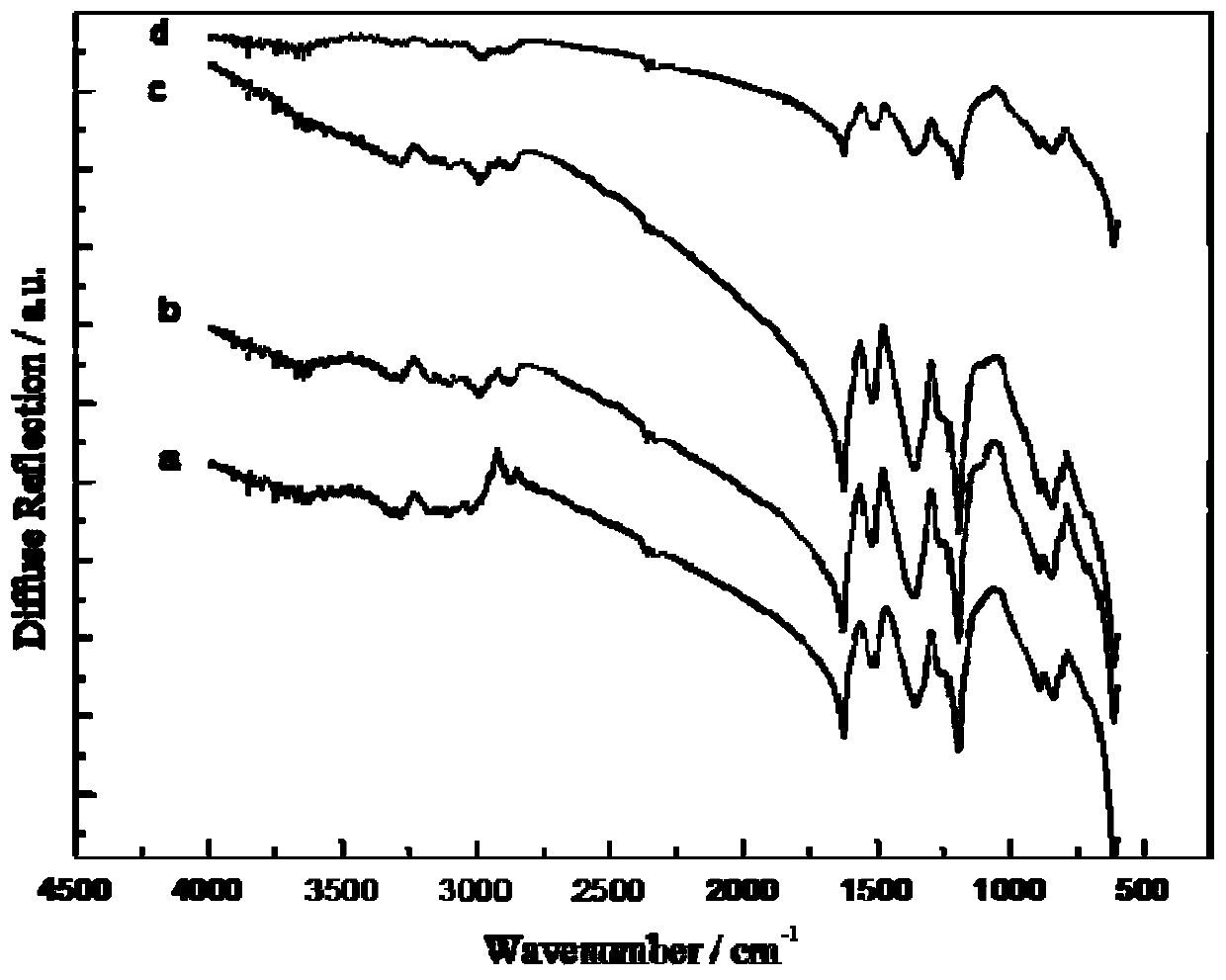

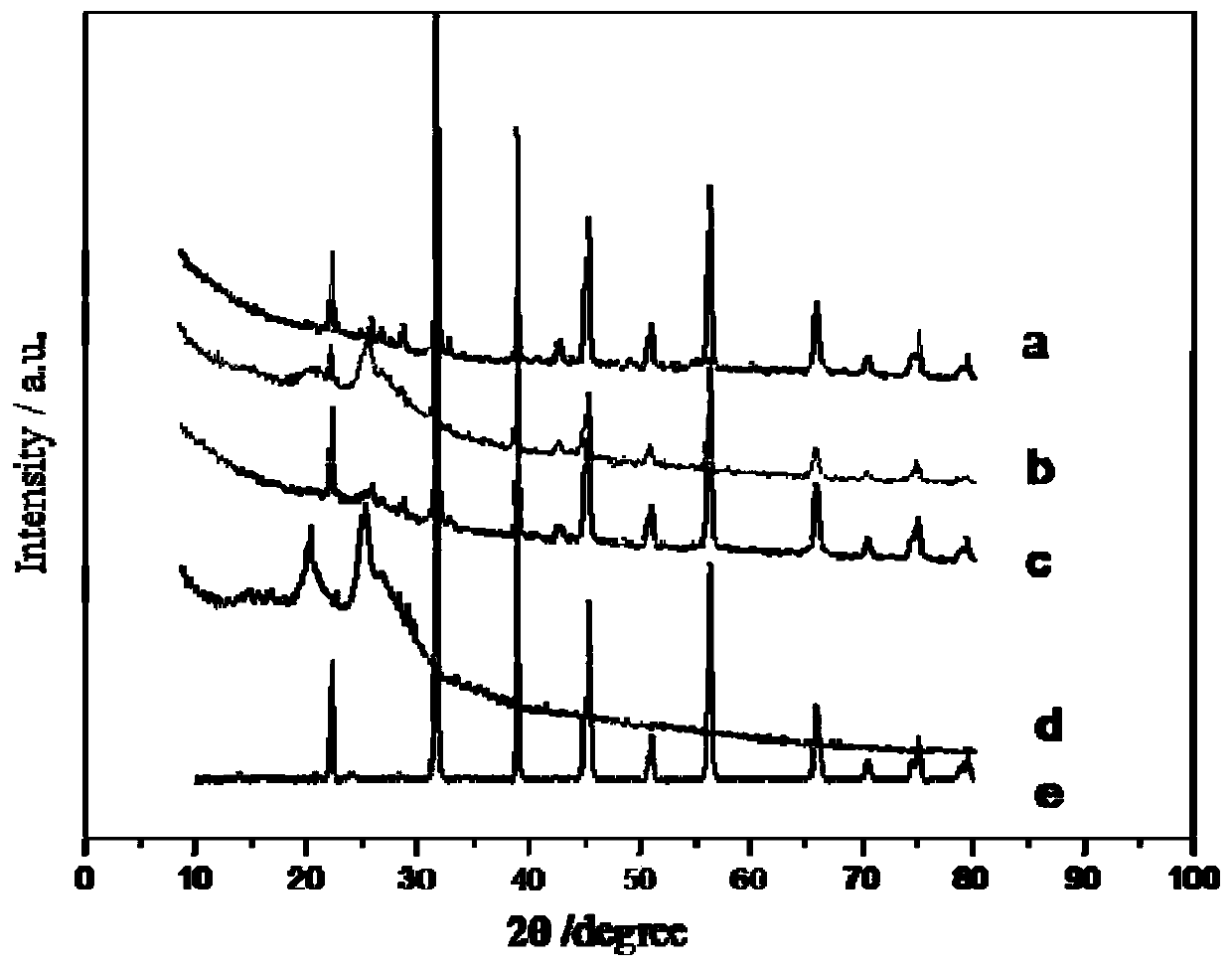

Embodiment 1

[0022] Weigh 40mmol of barium titanate at a molar ratio of aniline monomer / barium titanate of 1:1, add 40mmol of aniline monomer (0.4M) to 100mL H 2 SO 4 (0.5M) in aqueous solution. Under the condition of 0°C, stir with a magnetic stirrer for 30 minutes, and slowly add 100 mL of 0.4M ammonium persulfate solution to the above solution dropwise. The solution turned dark green with the addition of ammonium persulfate solution. After the reaction mixture was continuously stirred for 3 hours, it was left standing at 0° C. for 24 h. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the precipitate after suction filtration was collected. with H 2 SO 4 , deionized water and acetone to wash the filter cake until the filtrate is neutral. The resulting precipitate was dried under vacuum at 60°C for 24 hours. After grinding, a dark green polyaniline / barium titanate composite material was obtained.

Embodiment 2

[0024] Weigh 20mmol of barium titanate at a molar ratio of aniline monomer / barium titanate of 2:1, add 40mmol of aniline (0.4M) to 100mL H 2 SO 4 (0.5M) in aqueous solution. Under the condition of 0°C, stir with a magnetic stirrer for 30 minutes, and slowly add 100 mL of 0.4M ammonium persulfate solution to the above solution dropwise. The solution turned dark green with the addition of ammonium persulfate solution. After the reaction mixture was continuously stirred for 3 hours, it was left standing at 0° C. for 24 h. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the precipitate after suction filtration was collected. with H 2 SO 4 , deionized water and acetone to wash the filter cake until the filtrate is neutral. The resulting precipitate was dried under vacuum at 60°C for 24 hours. After grinding, a dark green polyaniline / barium titanate composite material was obtained.

Embodiment 3

[0026] Weigh 13.3mmol of barium titanate at a molar ratio of aniline monomer / barium titanate of 3:1, add 40mmol of aniline (0.4M) to 100mL H 2 SO 4 (0.5M) in aqueous solution. Under the condition of 0°C, stir with a magnetic stirrer for 30 minutes, and slowly add 100 mL of 0.4M ammonium persulfate solution to the above solution dropwise. The solution turned dark green with the addition of ammonium persulfate solution. After the reaction mixture was continuously stirred for 3 hours, it was left standing at 0° C. for 24 h. After the reaction was completed, suction filtration was carried out with a Buchner funnel, and the precipitate after suction filtration was collected. with H 2 SO 4 , deionized water and acetone to wash the filter cake until the filtrate is neutral. The resulting precipitate was dried under vacuum at 60°C for 24 hours. After grinding, a dark green polyaniline / barium titanate composite material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com