Blocking agent and application thereof

A technology of plugging agent and bridging agent, applied in the field of plugging agent, can solve problems such as the difficulty in controlling the temperature of gel material, the inability of coarse-grained plugging materials to enter the formation, and the difficulty in matching the particle size of bridge plugging materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Attapulgite powder: attapulgite powder containing dolomite in a mass content of 10% and having a particle size of 10 to 30 μm. Purchased from Anhui Boshuo Technology Co., Ltd. First of all, the microscopic morphology of the attapulgite used in this example dispersed in water was analyzed with a JEOL JSM-6701F cold field emission scanning electron microscope, and the analysis results are shown in figure 1 . From figure 1 It can be seen that the crystal part of the attapulgite is rod-shaped microscopically, with a relatively large major diameter and a diameter of 50 to 100 nm, so it is judged that it is easy to enter the fractures in the formation.

[0045] The particle sizes of melamine and cyanuric acid are 10 to 30 μm, respectively.

[0046] 100g of cyanuric acid and 100g of melamine were reacted in 50g of water at 170°C to form a crystallization agent, and the microscopic morphology, particle size distribution and temperature resistance characteristics were observe...

Embodiment 2

[0050] Attapulgite powder: attapulgite powder containing dolomite in a mass content of 20%, with a particle size of 30 to 50 μm. Purchased from Anhui Boshuo Technology Co., Ltd. After being dispersed in water, its diameter is 100 to 200 nm.

[0051] The particle sizes of melamine and cyanuric acid are 30 to 50 μm, respectively.

[0052] In the mixing tank, add 35kg of clear water, start the high-speed shear mixer at a speed of 8000rpm, add attapulgite powder 40kg, 12.2kg of melamine, 12.8kg of cyanuric acid, and 0.6kg of stearic acid in turn, and stir evenly to obtain a sealed Blocking agent 2#.

[0053] Put the prepared plugging agent 2 into the aging tank, raise the temperature to 210°C, heat for two hours, then cool down rapidly, filter the product, and observe the microscopic morphology of the filter cake, see Figure 8 , Figure 9 and Figure 10 .

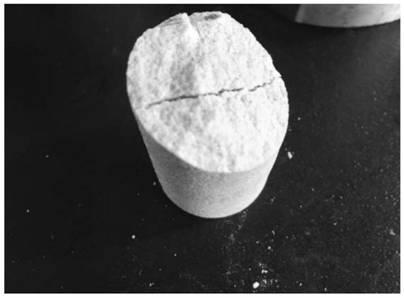

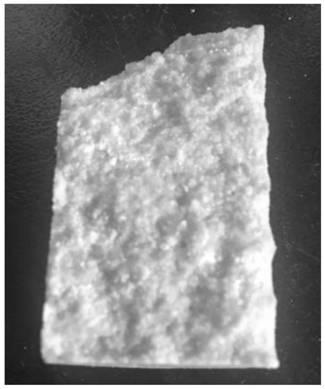

[0054] After the man-made core has been processed to produce cracks, see Figure 11 and Figure 12 , put it into the a...

Embodiment 3

[0056] Attapulgite powder: attapulgite powder containing dolomite in a mass content of 5%, with a particle size of 20 to 30 μm. Purchased from Anhui Boshuo Technology Co., Ltd. After being dispersed in water, its diameter is 50 to 150 nm.

[0057] The particle sizes of melamine and cyanuric acid are 20 to 30 μm, respectively.

[0058] In the mixing tank, add 34.4kg of clear water, start the high-speed shear mixer at a speed of 2000rpm, add attapulgite powder 40kg, 12.2kg of melamine, 12.8kg of cyanuric acid, and 0.6kg of stearic acid in turn, and stir evenly to obtain Plugging agent 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com