Pit mud control device for white wine pit

A control device and cellar technology, which is applied in the field of wine making, can solve the problems of easy aging and degradation control of pit mud, and achieve the effects of facilitating fermentation, improving stability, and preventing blockage of pit mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

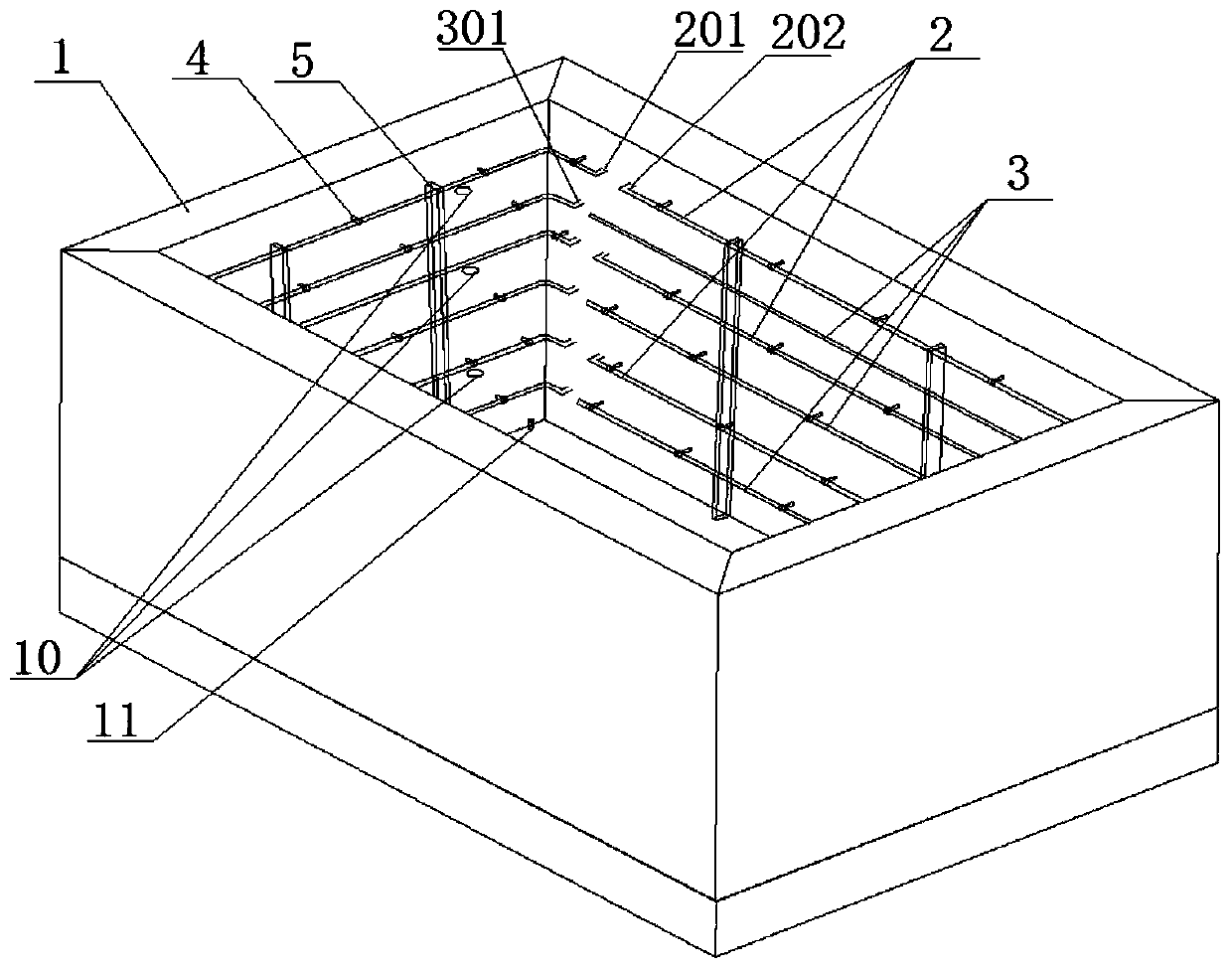

[0038] Take the brewing of Luzhou-flavor liquor as an example, such as figure 1 and figure 2 As shown, the cellar mud control device for liquor cellars of the present invention includes a cellar 1, and also includes a temperature adjustment mechanism and a nutrient delivery mechanism arranged on the inner wall of the cellar 1;

[0039] The temperature adjustment mechanism includes three temperature adjustment tubes 2 arranged in the height direction of the cellar 1, each of the temperature adjustment tubes 2 is provided with a first medium inlet 201 at one end and a first medium outlet 202 at the other end;

[0040] The nutrient delivery mechanism includes three delivery pipes 3 arranged in the height direction of the cellar 1, each delivery pipe 3 is provided with a second medium inlet 301 at one end, and the other end is closed, and each delivery pipe 3 is uniformly provided with delivery holes 302;

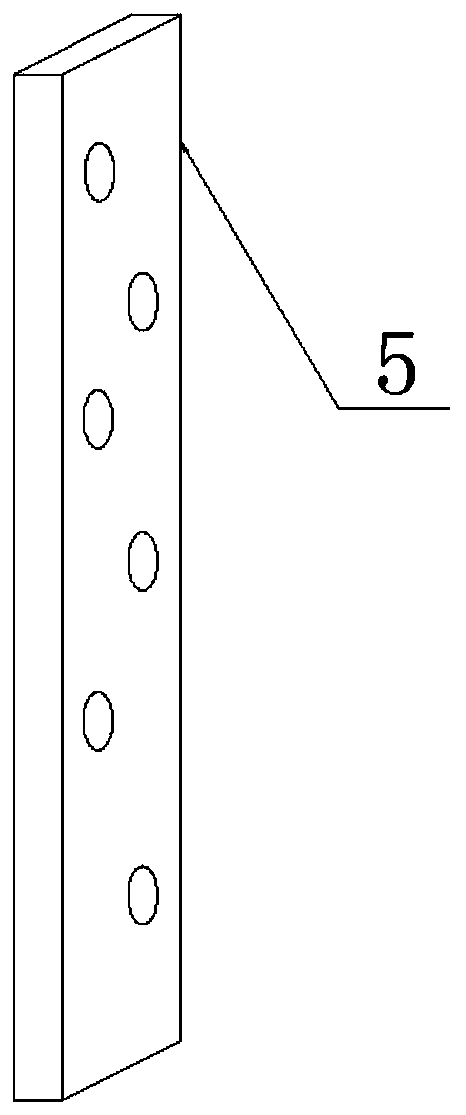

[0041] Both the temperature regulating pipe 2 and the delivery pipe 3 are...

Embodiment 2

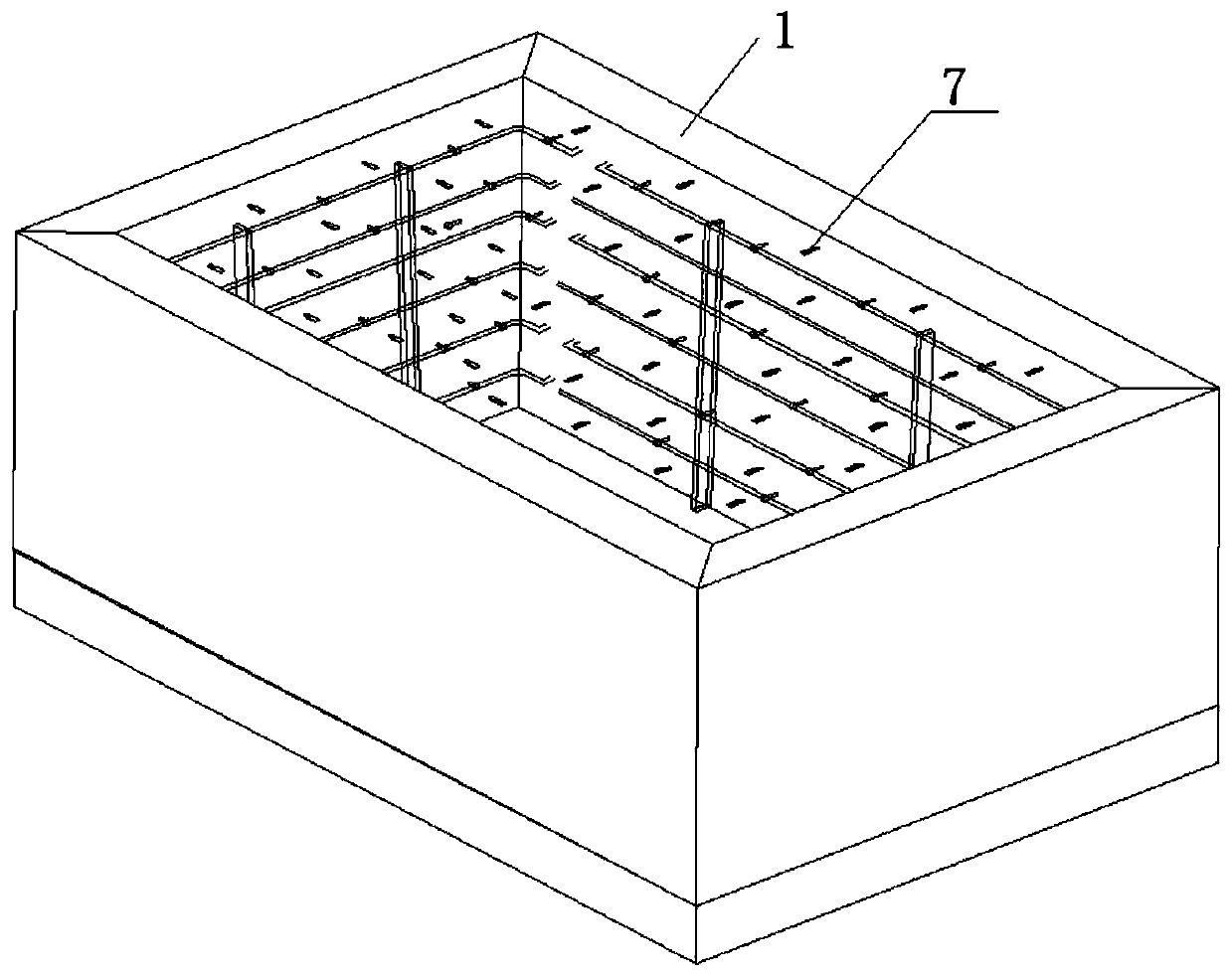

[0049] Such as image 3 and Figure 4 As shown, this embodiment is a further improvement made on the basis of Embodiment 1, and a fixing mechanism is also provided in the cellar 1; the fixing mechanism includes support columns 7 evenly arranged on the inner wall of the cellar 1 The rope net 8 on the support column 7, the support column 7 is a bamboo nail, which can further fix the pit mud on the base plate.

Embodiment 3

[0051] Such as Figure 5 ~ Figure 8 As shown, the present embodiment is a further improvement made on the basis of Embodiment 2. A bamboo curtain 9 is also arranged on the inner wall of the cellar pool 1, and the temperature adjustment mechanism, the nutrient delivery mechanism and the fixing mechanism are all passed through the bamboo curtain 9. It is connected with the inner wall of the cellar 1; the surface of the support 5 is provided with a second fiber cloth 501, and the second fiber cloth 501 and the cellar 1 are enclosed to form a cavity 6, and the temperature adjustment mechanism and the nutrient delivery mechanism are both set In the cavity 6 ; the conveying pipe 3 is arranged on a side of the cavity 6 close to the second fiber cloth 501 . The pit mud is further fixed to prevent the pit mud from falling into the fermented grains, so as to prevent the brewed wine lees from being too strong and affecting the taste. The distance from the second fiber cloth 501 to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com