Construction method of a sewage pipeline

A construction method and technology for sewage pipelines, which are applied in the sewer system, waterway system, water conservancy projects, etc., can solve the problems of water pollution, lagging drainage facilities, restricting rural development, etc., to ensure stability, reduce disturbance, and improve bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

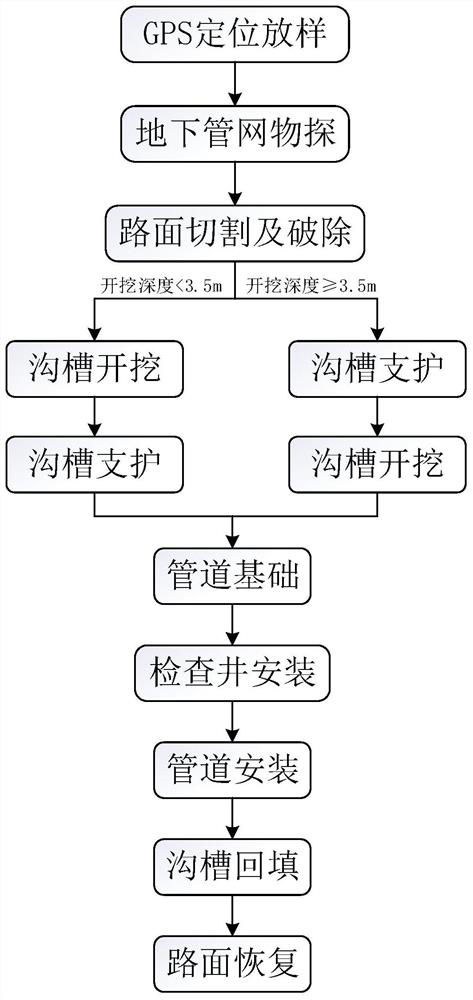

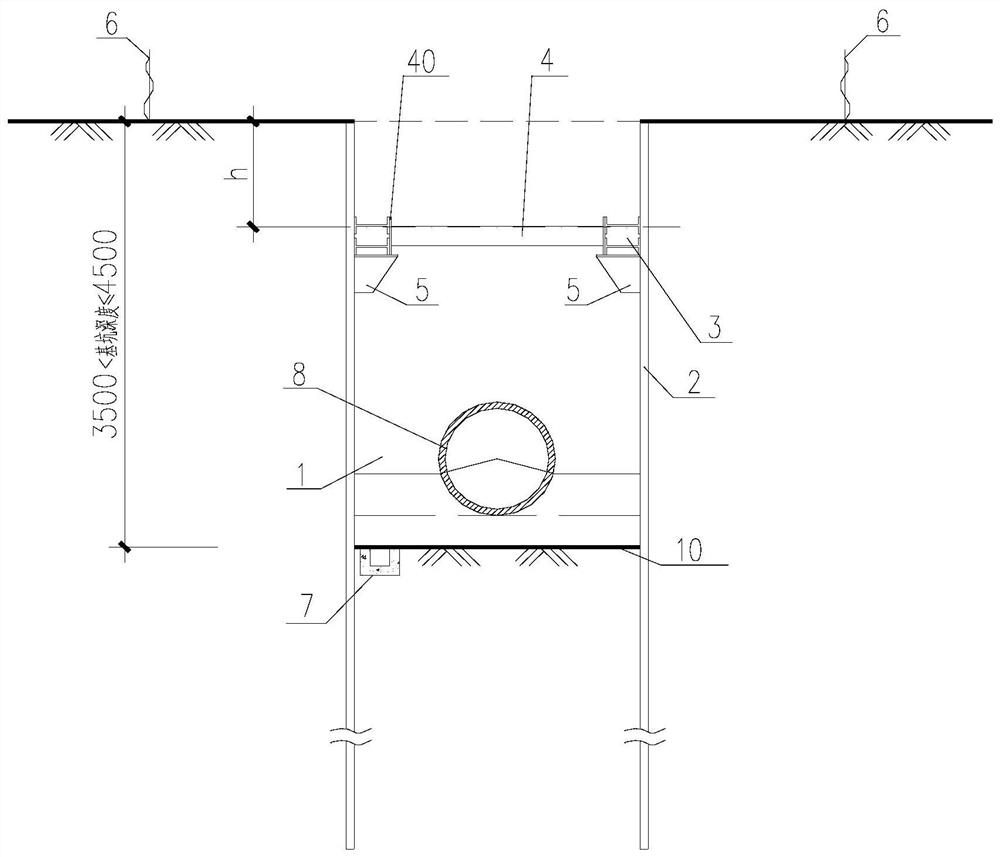

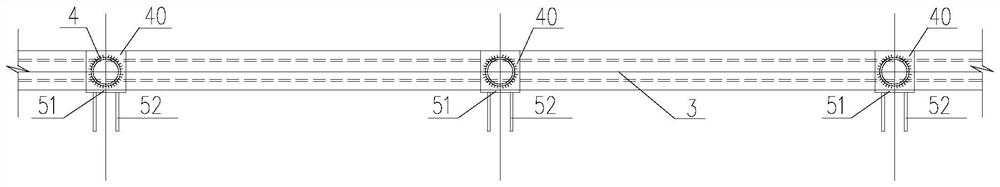

[0056] see Figure 1 to Figure 3 , the construction method of a kind of sewage pipeline of the present invention comprises the following processes: GPS positioning and lofting, road surface cutting and breaking, pipeline trench support and excavation, pipeline foundation construction, inspection well installation, pipeline installation, pipeline trench backfilling and road surface recover;

[0057] When carrying out the GPS positioning and stakeout process, according to the pipeline coordinate data provided by the design, carry out the stakeout of the sewage pipeline axis in the construction section, use GPS combined with the total station for detailed measurement and stakeout work, and determine the specific location of the construction according to the released well position;

[0058] When carrying out the pavement cutting and demolition process, follow the steps below: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com