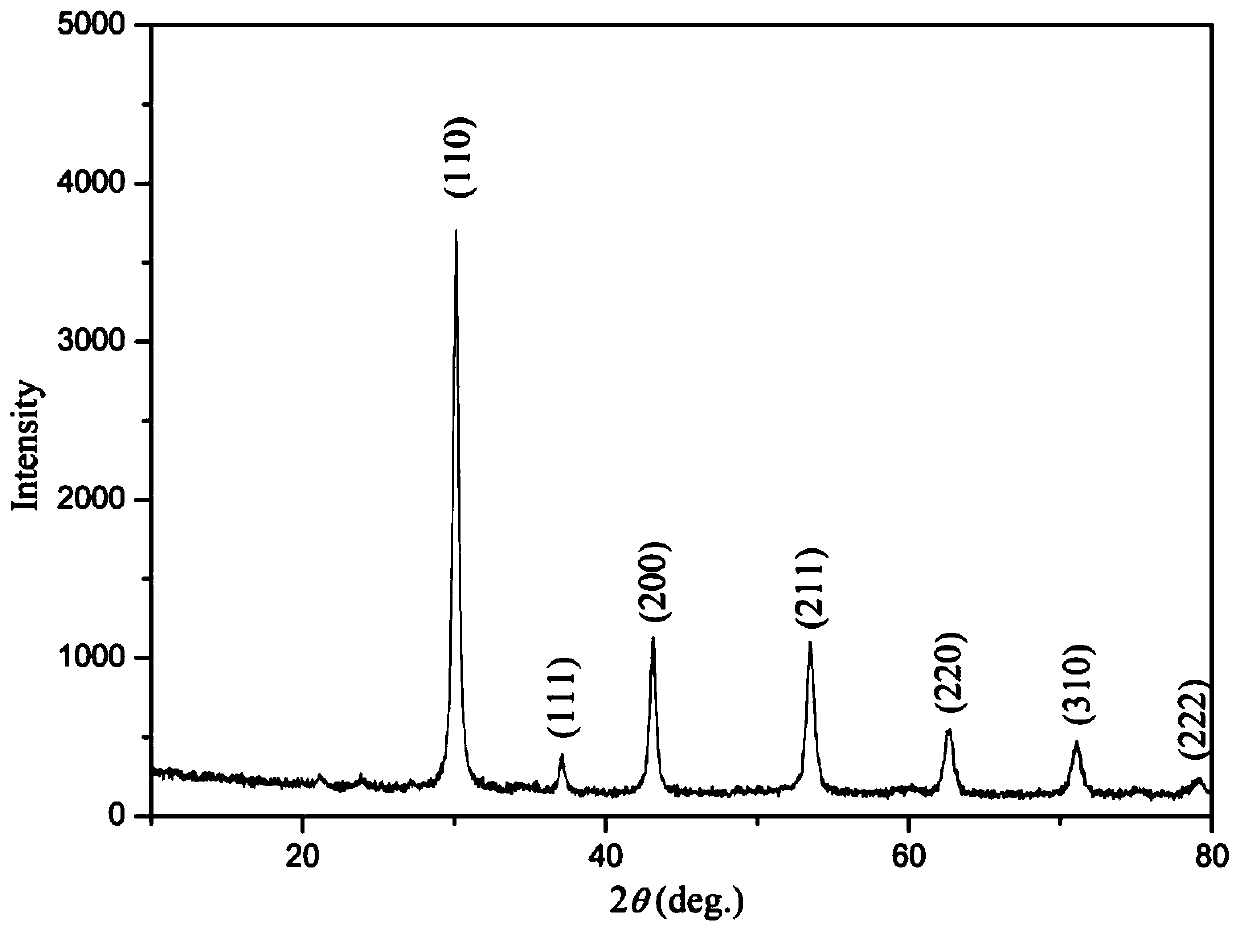

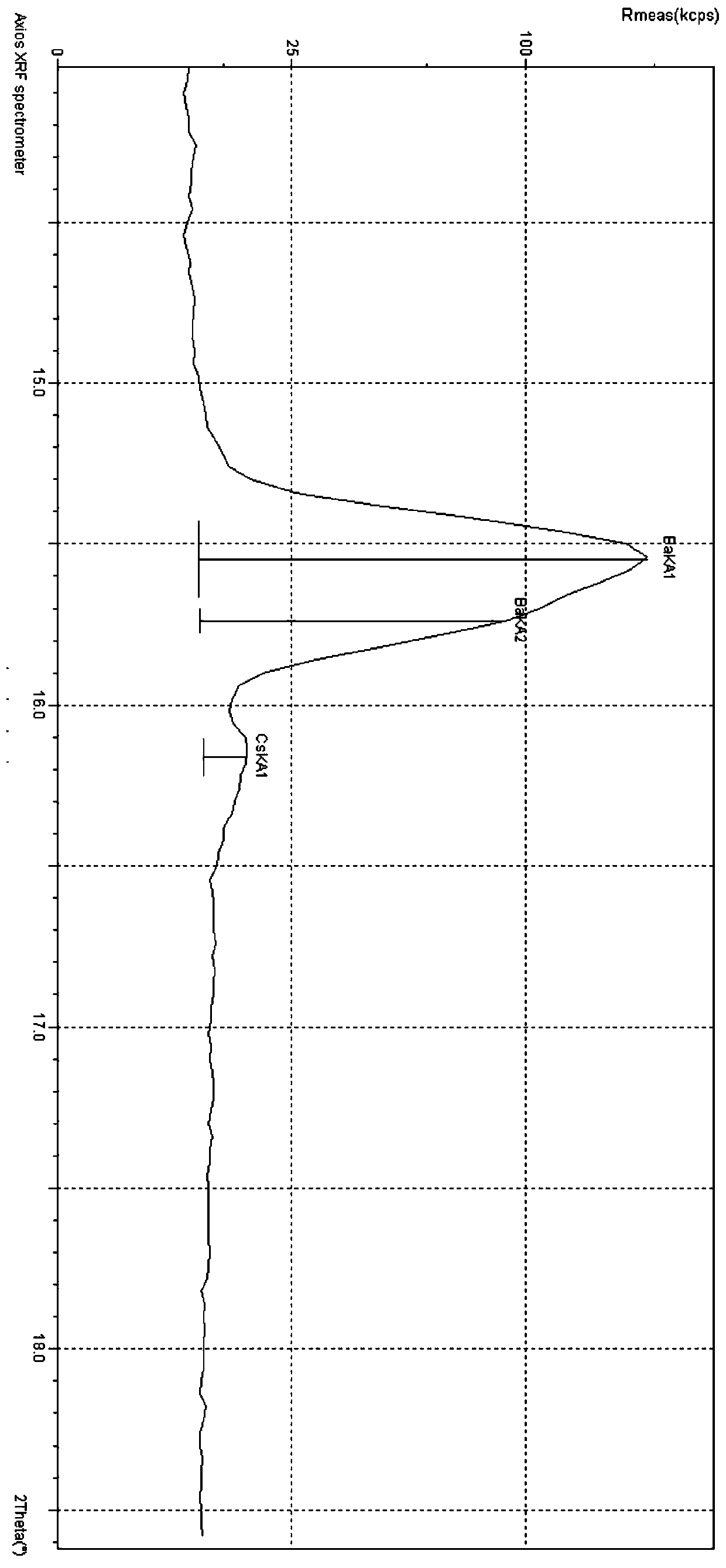

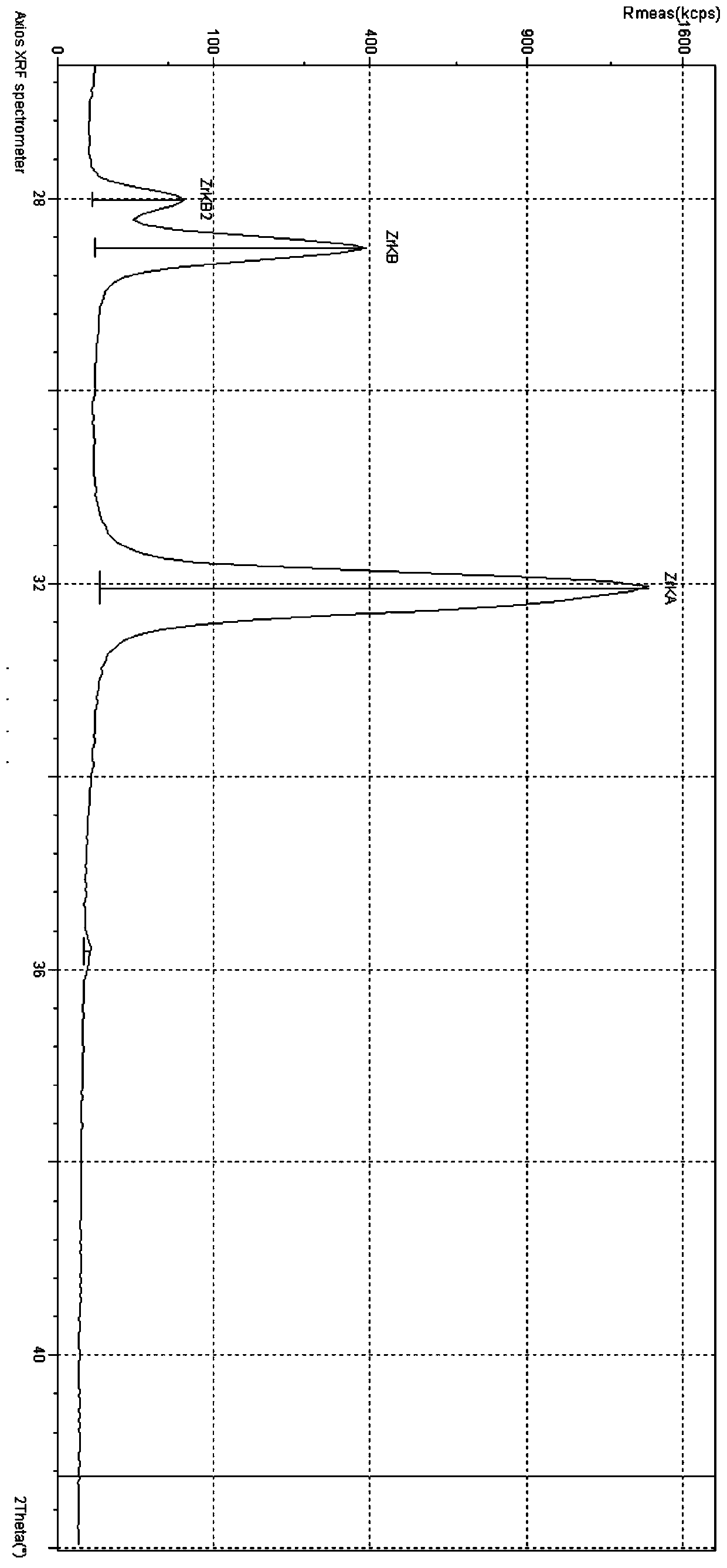

Method for solidifying radioactive nuclide fission product cesium by perovskite structure oxide

A radionuclide and perovskite structure technology is applied in the field of solidifying radionuclide fission products by using perovskite structure oxides, which can solve the problems of Cs volatilization, long preparation time, Cs element volatilization, etc. The effect of low leaching rate and strong self-adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for solidifying radionuclide fission product cesium by using a perovskite structure oxide, comprising the following steps:

[0028] Step 1, take the Ba(NO with a molar ratio of 0.9:0.1:1 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 O is added to deionized water, and stirred at a speed of 300r / min for 10min; the deionized water and Zr(NO 3 ) 2 ·5H 2 The molar ratio of O is 1:1;

[0029] Step 2, add citric acid in the solution after step 1 stirring, stir and chelate with the speed of 300r / min 1h; Described citric acid and Ba(NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2The molar ratio of the total cations of O is 3:1;

[0030] Step 3, add acrylamide to the solution after stirring and chelating in step 2, then stir at a speed of 300r / min for 0.5h, then slowly heat up to 120°C until the sol becomes a gel; the acrylamide and Ba(NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 The molar ratio of the total cations of O is 9:1;

[0031] Step 4. Dry the prepared gel in a ...

Embodiment 2

[0038] A method for solidifying radionuclide fission product cesium by using a perovskite structure oxide, comprising the following steps:

[0039] Step 1, take the Ba(NO with a molar ratio of 0.8:0.2:1 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 O is added to deionized water, and stirred at a speed of 300r / min for 10min; the deionized water and Zr(NO 3 ) 2 ·5H 2 The molar ratio of O is 1:1;

[0040] Step 2, add citric acid in the solution after step 1 stirring, stir and chelate with the speed of 300r / min 1h; Described citric acid and Ba(NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 The molar ratio of the total cations of O is 3:1;

[0041] Step 3, add polyvinyl alcohol to the solution after stirring and chelating in step 2, then slowly heat up to 120°C after stirring at a speed of 300r / min for 0.5h, until the sol becomes a gel; the polyvinyl alcohol and Ba( NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 The molar ratio of the total cations of O is 9:1;

[0042] Step 4. Dry ...

Embodiment 3

[0046] A method for solidifying radionuclide fission product cesium by using a perovskite structure oxide, comprising the following steps:

[0047] Step 1, take the Ba(NO with a molar ratio of 0.7:0.3:1 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 O is added to deionized water, and stirred at a speed of 300r / min for 10min; the deionized water and Zr(NO 3 ) 2 ·5H 2 The molar ratio of O is 1:1;

[0048] Step 2, add citric acid in the solution after step 1 stirring, stir and chelate with the speed of 300r / min 1h; Described citric acid and Ba(NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 The molar ratio of the total cations of O is 3:1;

[0049] Step 3, add polyacrylic acid to the solution after stirring and chelating in step 2, then stir at a speed of 300r / min for 0.5h and then slowly heat up to 120°C until the sol becomes a gel; the polyacrylic acid and Ba(NO 3 ) 2 , CsNO 3 and Zr(NO 3 ) 2 ·5H 2 The molar ratio of the total cations of O is 9:1;

[0050] Step 4. Dry the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com