Method for preparing ternary precursor of lithium battery by cyclic electrolysis

A precursor, lithium battery technology, applied in electrical components, electrolysis process, electrolysis components, etc., can solve the problems of high production cost, nickel-cobalt-manganese-containing waste water, poor product morphology and performance consistency, etc. The effect of simplifying the reaction control and reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

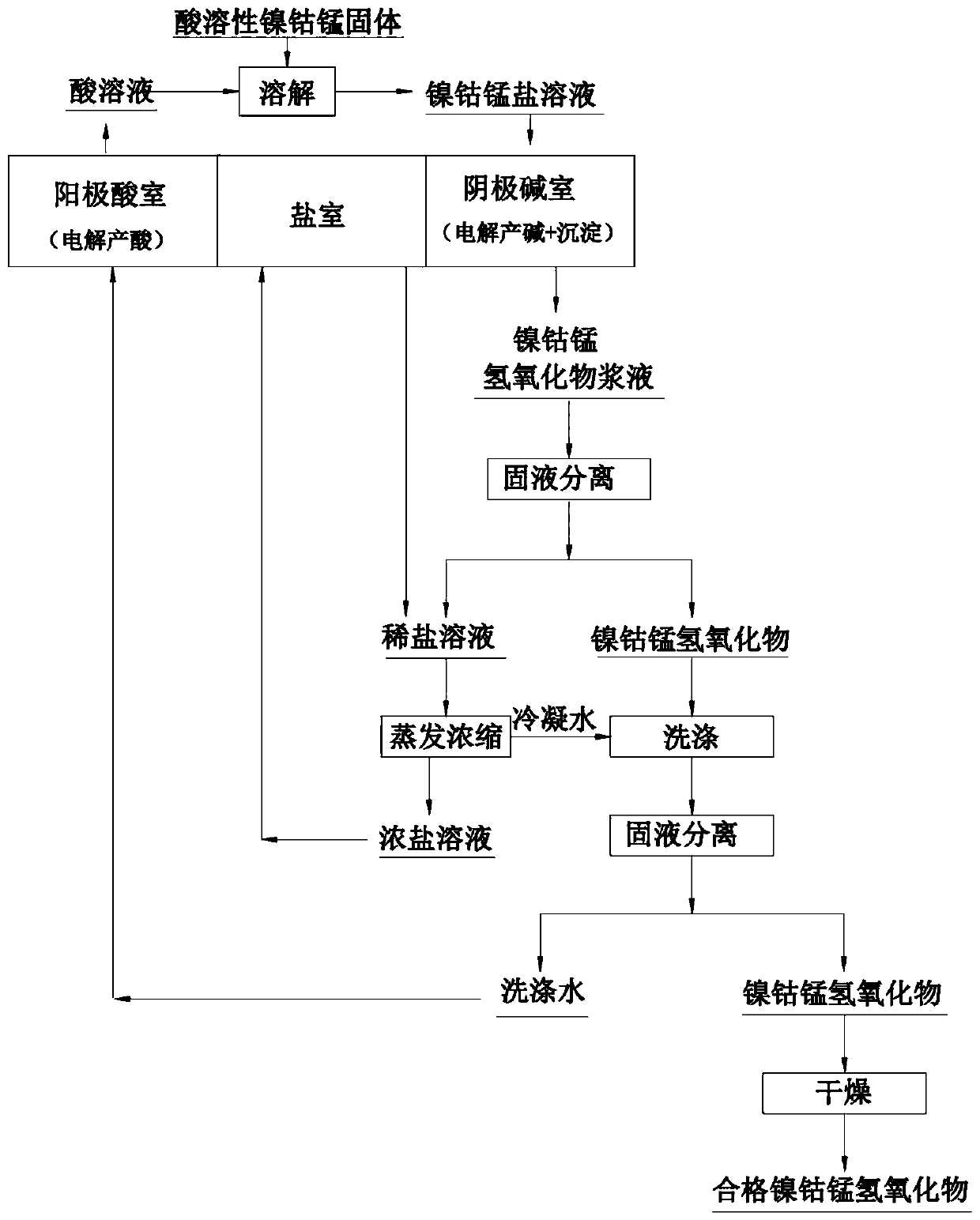

[0034] A method for preparing a lithium battery ternary precursor by cyclic electrolysis, comprising the following steps:

[0035] (1) Preparation of lithium sulfate solution

[0036] Configuration concentration is the lithium sulfate solution of 4mol / L, then adds a certain amount of ethanol, obtains the qualified lithium sulfate solution that lithium sulfate concentration is 4mol / L, ethanol volume concentration is 0.1%;

[0037] (2) Preparation of nickel-cobalt-manganese salt solution

[0038] Nickel carbonate, cobalt carbonate and manganese carbonate solid matter according to Ni 2+ :Co 2+ :Mn 2+ Molar ratio is that 5:2:3 ratio is mixed, then it is mixed with sulfuric acid solution, obtains mass concentration and is the cobalt nickel manganese sulfate solution of 20%; Simultaneously, the sulfuric acid solution that follow-up step (3) electrolysis obtains can be returned to Used in step (2);

[0039] (3) Three-chamber membrane electrolysis reaction

[0040] At a voltage ...

Embodiment 2

[0052] A method for preparing a lithium battery ternary precursor by cyclic electrolysis, comprising the following steps:

[0053] (1) Preparation of lithium sulfate solution

[0054] Configuration concentration is the lithium sulfate solution of 5mol / L, then adds a certain amount of acetaldehyde, obtains the qualified lithium sulfate solution that lithium sulfate concentration is 5mol / L, acetaldehyde volume concentration is 0.15%;

[0055] (2) Preparation of nickel-cobalt-manganese salt solution

[0056] Nickel carbonate, cobalt carbonate and manganese carbonate solid matter according to Ni 2+ :Co 2+ :Mn 2+ The molar ratio is mixed in a ratio of 6:2:2, and then it is mixed with sulfuric acid solution to obtain a cobalt-nickel-manganese sulfate solution with a mass concentration of 20%; meanwhile, the sulfuric acid solution obtained by subsequent step (3) electrolysis can be returned to To use in step (2);

[0057] (3) Three-chamber membrane electrolysis reaction

[0058...

Embodiment 3

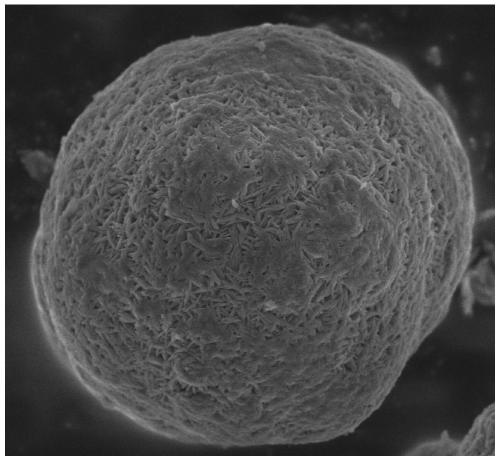

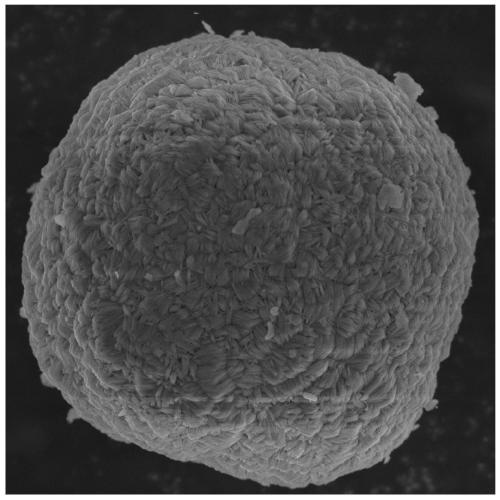

[0070] Under the same conditions, the chemical composition, tap density and other performance parameters of the precursors prepared in Example 1 and Example 2 were tested respectively, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com