A kind of lithium battery cathode material precursor with mesoscopic structure and preparation method thereof

A positive electrode material and mesoscopic structure technology, applied in the field of lithium battery positive electrode material precursors and its preparation, can solve the problem of not being able to prepare lithium nickel cobalt manganese quaternary precursors with mesoscopic structure, and achieve the promotion of particle adhesion and crystallization effect, benefit to rate performance, effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

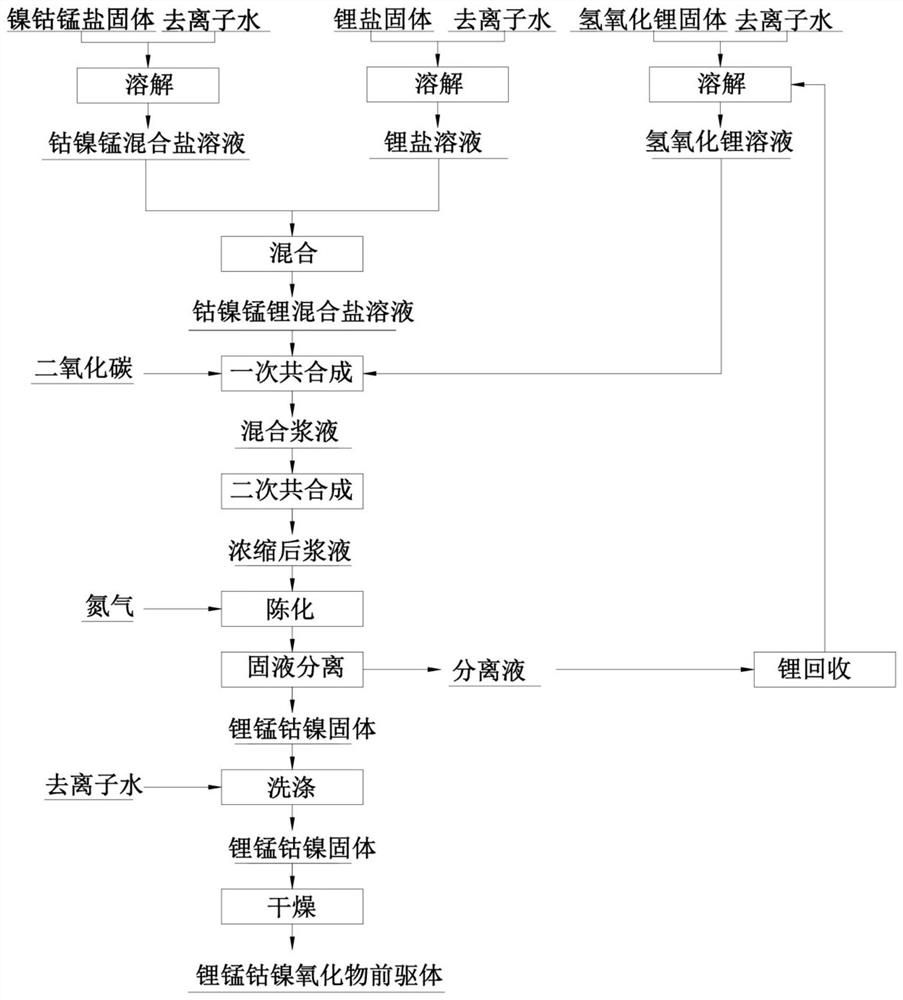

[0039] A preparation method of a lithium battery cathode material precursor with a mesoscopic structure, comprising the following steps:

[0040] (1) Solution deployment: the lithium sulfate solid soluble in water and deionized water are made into the lithium salt solution that concentration is 5mol / L; Lithium hydroxide solid and deionized water are made into the hydroxide that concentration is 5mol / L Lithium solution; water-soluble nickel sulfate, cobalt sulfate, manganese sulfate solid according to Ni 2+ :Mn 2+ :Co 2+ The molar ratio was 5:2:3, and then the mixture was dissolved in deionized water to form a mixed solution of manganese, cobalt and nickel salts with a concentration of 4 mol / L.

[0041] (2) One-time co-synthesis reaction: Add the mixed solution of nickel-cobalt-manganese salt and lithium salt solution obtained in step (1) into the synthesis reaction device with stirring and heating, and add the solution to the solution according to the 2m 3 The flow rate of / h...

Embodiment 2

[0048] A preparation method of a lithium battery cathode material precursor with a mesoscopic structure, comprising the following steps:

[0049] (1) Solution preparation: water-soluble lithium chloride solid and deionized water are made into lithium salt solution with a concentration of 9mol / L; lithium hydroxide solid and deionized water are made into hydrogen with a concentration of 6mol / L Lithium oxide solution; water-soluble nickel chloride, cobalt chloride, manganese chloride solid according to Ni 2+ :Mn 2+ :Co 2+ The molar ratio was 6:2:2, and then the mixture was dissolved with deionized water to form a mixed solution of manganese, cobalt and nickel salts with a concentration of 5 mol / L.

[0050] (2) One-time co-synthesis reaction: add the mixed solution of nickel-cobalt-manganese salt and lithium salt solution obtained in step (1) into the synthesis reaction device with stirring and heating, 3 The flow rate of / h is fed into carbon dioxide gas, and the pH automatic ...

experiment example

[0059] The precursors prepared in Example 1, Example 2 and Comparative Example were respectively used as raw materials to prepare lithium battery positive electrodes, and then according to the non-ferrous metal industry standard of the People's Republic of China (YST 798-2012), it was tested for charge and discharge performance. The results are shown in Table 1.

[0060] Table 1 Lithium battery cathode charging performance

[0061]

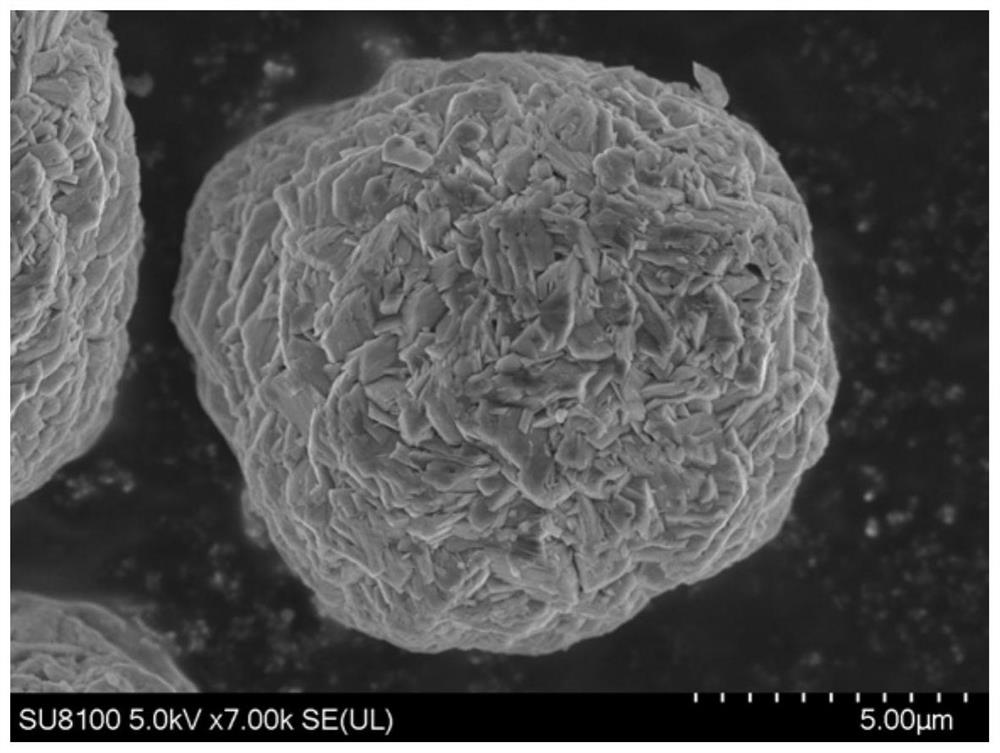

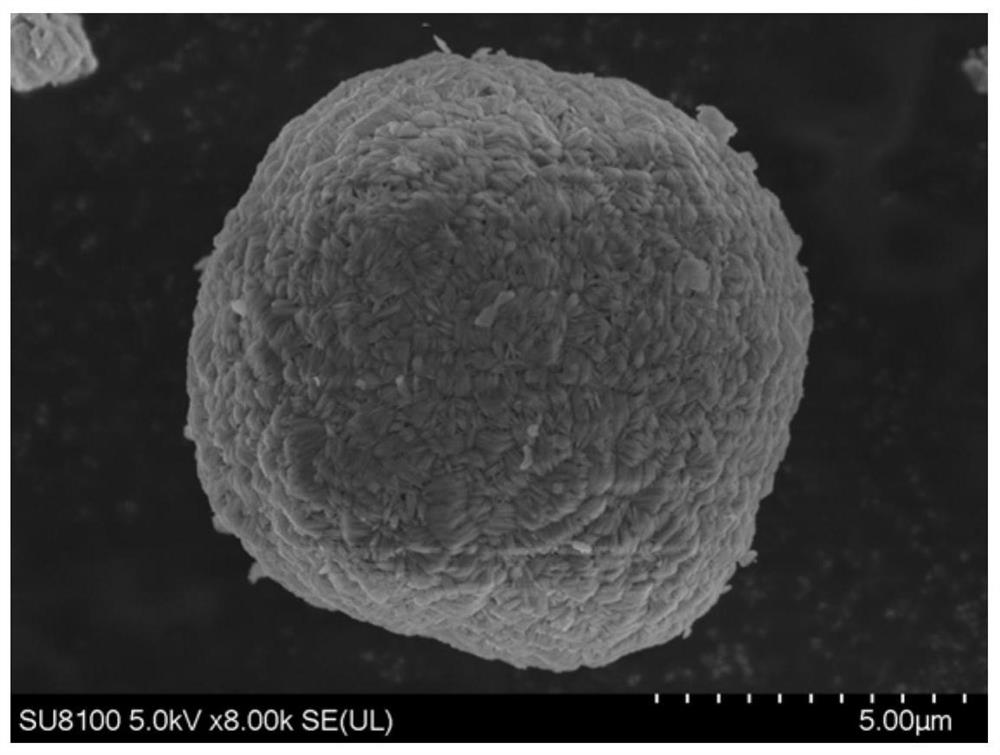

[0062] From the data in Table 1, it can be seen that the performance of the positive electrodes of lithium batteries prepared using the precursors prepared in Example 1 and Example 2 of the present invention as raw materials is almost the same, and both are higher than the industry standard, and are far better than the comparative example, which shows that , only with the cooperation of the method and process conditions of the present invention, can the lithium-nickel-cobalt-manganese quaternary precursor with nanoscale and mesoscopic structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com