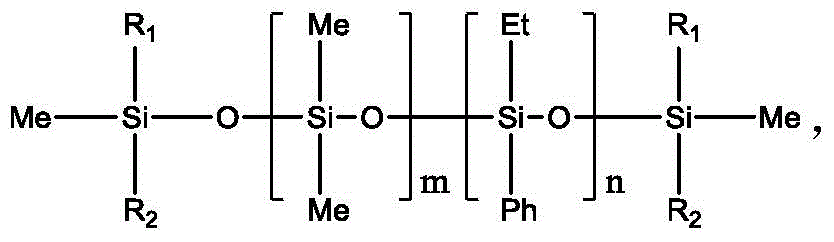

A kind of siloxane copolymer containing ethylphenyl siloxane chain unit and preparation method thereof

A technology of siloxane copolymer and ethylphenyldialkoxysilane, which is applied in the field of siloxane copolymer containing ethylphenylsiloxane chain members and its preparation, can solve the problem of separation difficulty and polymer performance Unfavorable, complex composition and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

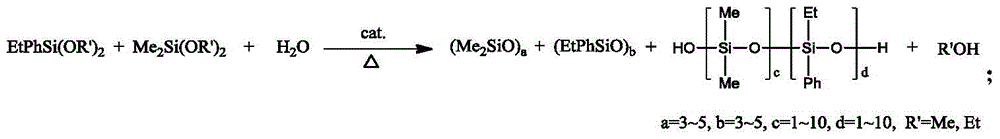

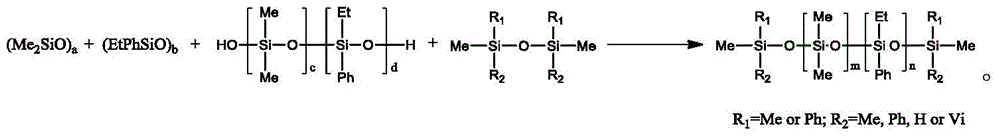

Method used

Image

Examples

Embodiment 1

[0063] Add 8.02g (0.0357mol) ethylphenyldiethoxysilane, 500.5g (3.3754mol) dimethyldiethoxysilane, 130g (7.2222mol) deionized water and 5g (0.2088mol) lithium hydroxide In a 1000mL four-necked round-bottomed flask equipped with a thermometer, constant pressure dropping funnel, mechanical stirring and distillation device, slowly raise the temperature until the material in the flask boils and refluxes, adjust the reflux ratio of the distillation device, and partially receive the overhead fraction, while opening the constant pressure drop The feed valve of the liquid funnel was used to slowly add deionized water dropwise to maintain the liquid level of the material in the round bottom flask basically unchanged. As the hydrolysis process proceeds, the temperature is gradually raised to keep the material in the round bottom flask always in a reflux state. The refractive index (nD 25 ), when the instantaneous refractive index of the sample (n D 25 ) close to 1.3325 (1.3325-1.3330...

Embodiment 2

[0066] 25g (0.1114mol) ethylphenyldiethoxysilane, 17.5g (0.1180mol) dimethyldiethoxysilane, 82.5g (4.5833mol) deionized water and 1.1g (0.0459mol) lithium hydroxide Add it into a 250mL four-neck round bottom flask equipped with a thermometer, constant pressure dropping funnel, mechanical stirring and distillation device, slowly raise the temperature until the material in the flask boils and reflux, adjust the reflux ratio of the distillation device, partially receive the overhead fraction, and open the constant pressure at the same time The feeding valve of the dropping funnel is used to slowly add deionized water dropwise to maintain the liquid level of the material in the round bottom flask basically unchanged. As the hydrolysis process proceeds, the temperature is gradually raised to keep the material in the round bottom flask always in a reflux state. The refractive index (n D 25 ), when the instantaneous refractive index of the sample (n D 25 ) close to 1.3325 (1.3325...

Embodiment 3

[0069] 10.8g (0.055mol) ethylphenyldimethoxysilane, 17.5g (0.1180mol) dimethyldiethoxysilane, 31.5g (1.75mol) deionized water and 0.05g (0.0009mol) hydroxide Potassium was added to a 250mL four-necked round-bottomed flask equipped with a thermometer, a constant pressure dropping funnel, mechanical stirring and a distillation device, and the temperature was slowly raised until the material in the flask boiled and refluxed, and the reflux ratio of the distillation device was adjusted to partially receive the overhead fraction. Press the feeding valve of the dropping funnel, and slowly add deionized water dropwise to keep the liquid level of the material in the round bottom flask basically unchanged. As the hydrolysis process proceeds, the temperature is gradually raised to keep the material in the round bottom flask always in a reflux state. The refractive index (n D 25 ), when the instantaneous refractive index of the sample (n D 25 ) close to 1.3325 (1.3325-1.3330), stop t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com