Titanium niobate negative electrode material and preparation method thereof

A negative electrode material, titanium niobate technology, applied in negative electrodes, chemical instruments and methods, titanates, etc., can solve the problems of large negative electrode sheet, reduce the energy density of lithium batteries, etc., and achieve high production efficiency and excellent ion conductivity. rate, the effect of increasing the discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

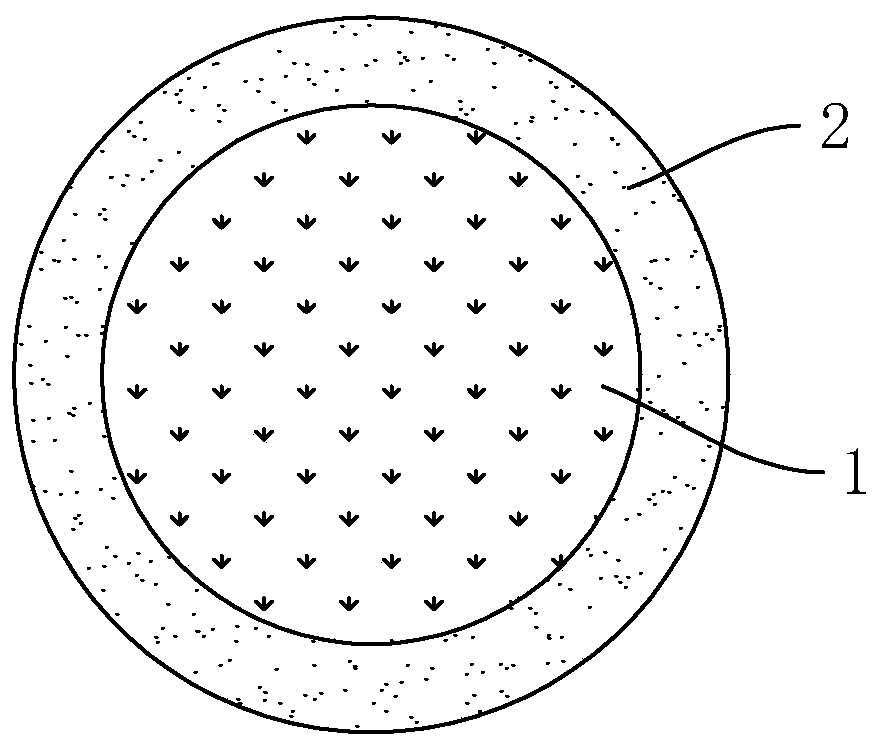

[0044] A kind of titanium niobate negative electrode material, see figure 1, including a core structure 1 and a shell structure 2 coated on the surface of the core structure 1, the core structure 1 is mainly composed of titanium niobate, and the shell structure 2 is mainly composed of lithium titanate.

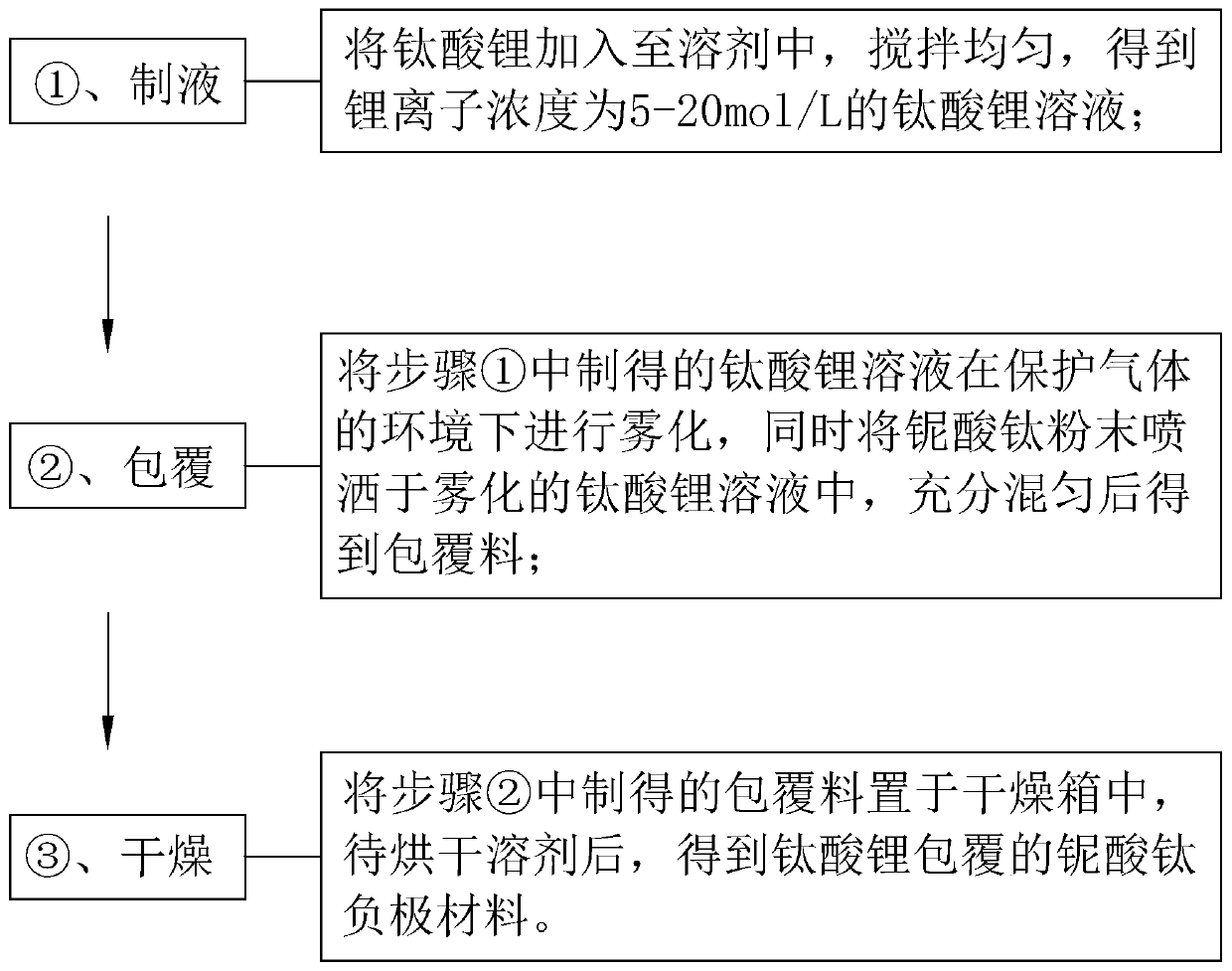

[0045] The preparation method of the above-mentioned titanium niobate negative electrode material comprises the following steps:

[0046] ①. Liquid preparation: add lithium titanate to ethanol, stir evenly to obtain a lithium titanate-ethanol solution with a lithium ion concentration of 15 mol / L.

[0047] ②, Coating: Pour the lithium titanate-ethanol solution prepared in step ① into the atomization device, and atomize it in a nitrogen environment, and at the same time, spray titanium niobate powder on the atomized lithium titanate-ethanol solution, mixed thoroughly to obtain the coating material. Wherein, the weight ratio of titanium niobate to lithium titanate is 1:0.2, and...

Embodiment 2- Embodiment 6

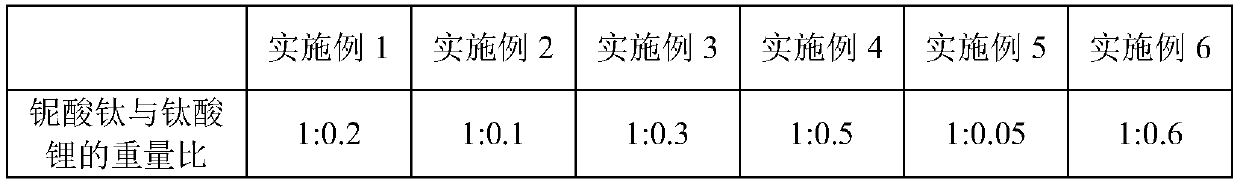

[0050] Embodiment 2-Example 6 are all based on the method of Example 1, and the weight ratio of titanium niobate to lithium titanate is adjusted, and the specific adjustment is shown in Table 1 below.

[0051] Table 1 The weight ratio of titanium niobate and lithium titanate in Example 1-Example 6

[0052]

Embodiment 7- Embodiment 11

[0054] Example 7-Example 11 are all based on the method of Example 1, and the particle size ratio of titanium niobate to lithium titanate is adjusted. For specific adjustments, see Table 2 below.

[0055] Table 2 The particle size ratio of titanium niobate and lithium titanate in Example 1, Example 7-Example 11

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com