Genetically engineered bacterium of high-yield threonine and application method thereof

A technology of genetically engineered bacteria and threonine, which is applied in the fields of genetic engineering and fermentation engineering, can solve the problems of short fermentation period, low conversion rate and low conversion rate of Escherichia coli, reduce the synthesis of by-product acetic acid, increase production, Enhance the effect of metabolic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

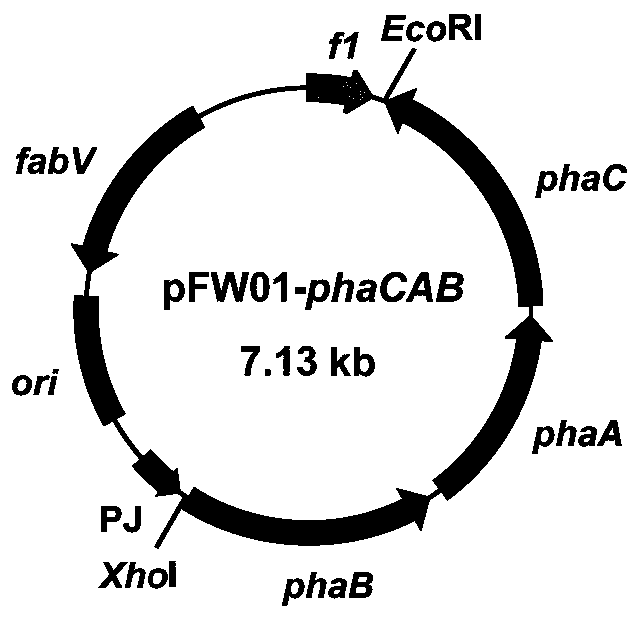

[0032] Example 1 Construction of Recombinant Bacteria TWF001 / pFW01-phaCAB

[0033] (1) Taking Eutropha rosenbergii genome NC_008313.1 as a template, primers phaCAB-F / phaCAB-R were used to amplify the phaCAB gene cluster, and the sequence of the primer phaCAB-F / phaCAB-R for amplifying the phaCAB gene cluster was

[0034] phaCAB-F: 5'-CTGCTCGAGAGAAGGAGAATCAAATCATGGCTACCGG-3'

[0035] phaCAB-R: 5'-CCG GAATTC AGGTCAGCCCATATGCAGG-3'

[0036](2) Digest the PCR product with restriction endonuclease XhoI and EcoRI, vector pFW01 (see the article "Increasing l-threonine production in Escherichia coli by engineering the glyoxylate shunt and the l-threonine biosynthesis pathway" for the construction method of vector pFW01) with EcoRI After digesting with XhoI and purifying the digested product, use T4 ligase to treat overnight at 22°C, transform into E. coli DH5α, and screen the correct transformants. For the obtained correct transformants, extract the plasmid and use 1.8kV, 5ms for el...

Embodiment 2

[0038] Example 2 Application of Escherichia coli Genetic Engineering Bacteria TWF001 / pFW01-phaCAB Shake Flask Fermentation to Produce PHB and L-Threonine (1) Shake Flask Fermentation of Recombinant Genetic Engineering Bacteria

[0039] Seed medium I: LB medium: 10g / L peptone, 5g / L yeast powder, 10g / L NaCl;

[0040] Shake flask fermentation medium I: 30g / L glucose, 25g / L (NH 4 ) 2 SO 4 , 7.5g / L KH 2 PO 4 , 2g / L yeast extract, 2g / L citric acid, 1g / L MgSO 4 ·7H 2 O, 5mg / L FeSO 4 ·7H 2 O, 5mg / L MnSO 4 4H 2 O, 20g / L CaCO 3 , pH 6.8 or pH 7.0;

[0041] Culture method: 37°C, 200rpm, culture for 36h.

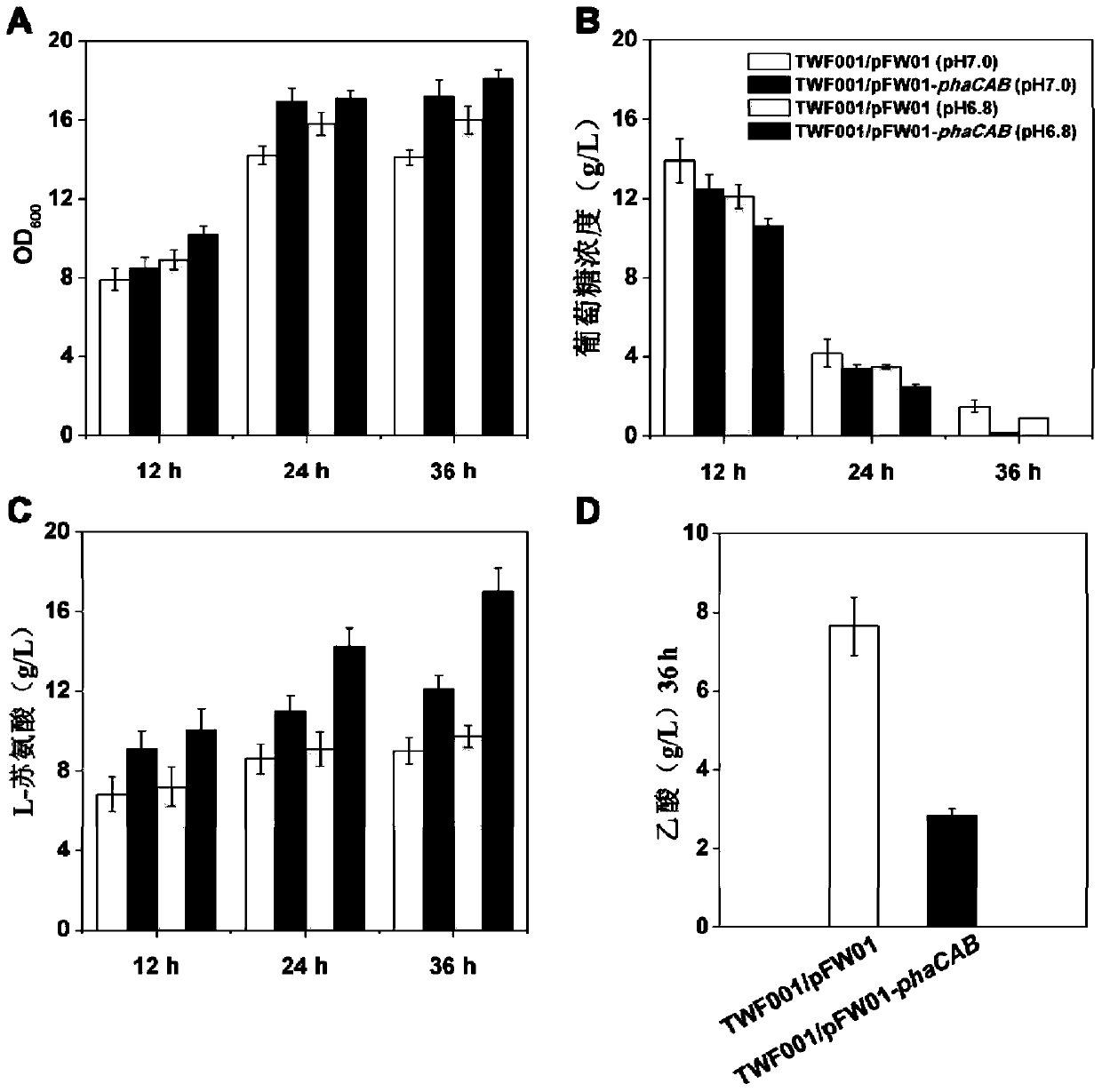

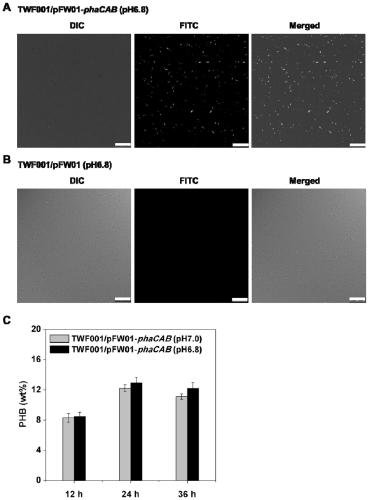

[0042] After the fermentation, under the condition of pH 6.8, more threonine was synthesized. The genetically engineered bacteria TWF001 / pFW01-phaCAB synthesized threonine 17.0g / L, the conversion coefficient of glucose was 0.57g / g, and the synthesis of acetic acid was 2.83g / L ; while the control bacteria TWF001 / pFW01 synthesized 9.72g / L threonine, the conversion coefficient...

Embodiment 4

[0061] (1) Determination of intracellular acetyl-CoA in recombinant bacteria TWF001 / pFW01-phaCAB and TWF001 / pFW01

[0062] Collect the OD prepared by step (1) in 2mL embodiment 2 600= 9.0 or so fermentation broth, put it on ice, and use the kit Acetyl-CoA Assay Kit (Solarbio, Beijing, China) to extract and measure acetyl-CoA, measure the light absorption value at 340nm, and the synthesis amount of acetyl-CoA By the formula Acetyl-CoA (nmol / g wetcell)=(1640*ΔA+0.012) / (OD 600 *1.7*0.002); ΔA=A 80s -A 20s Calculated, where A 80s OD of 80s after adding working solution 340nm , where A 20s OD 20s after adding working solution 340n .

[0063] The amount of acetyl-CoA synthesized by the genetically engineered bacteria TWF001 / pFW01-phaCAB per gram of wet cells was 4.51 μmol / g, while the amount of acetyl-CoA synthesized by the control bacteria TWF001 / pFW01 per gram of wet cells was 1.43 μmol / g;

[0064] (2) Determination of intracellular malic acid in recombinant bacteria TWF00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com