Coal economizer water temperature adjusting system under full-load denitration working condition

A technology of water temperature adjustment and economizer, which is applied to feed water heaters, preheating, steam generation, etc., can solve the problems of difficult implementation, difficult piping layout and construction of the heat recovery system, etc., and achieves convenient implementation of renovation projects and small renovation workload. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

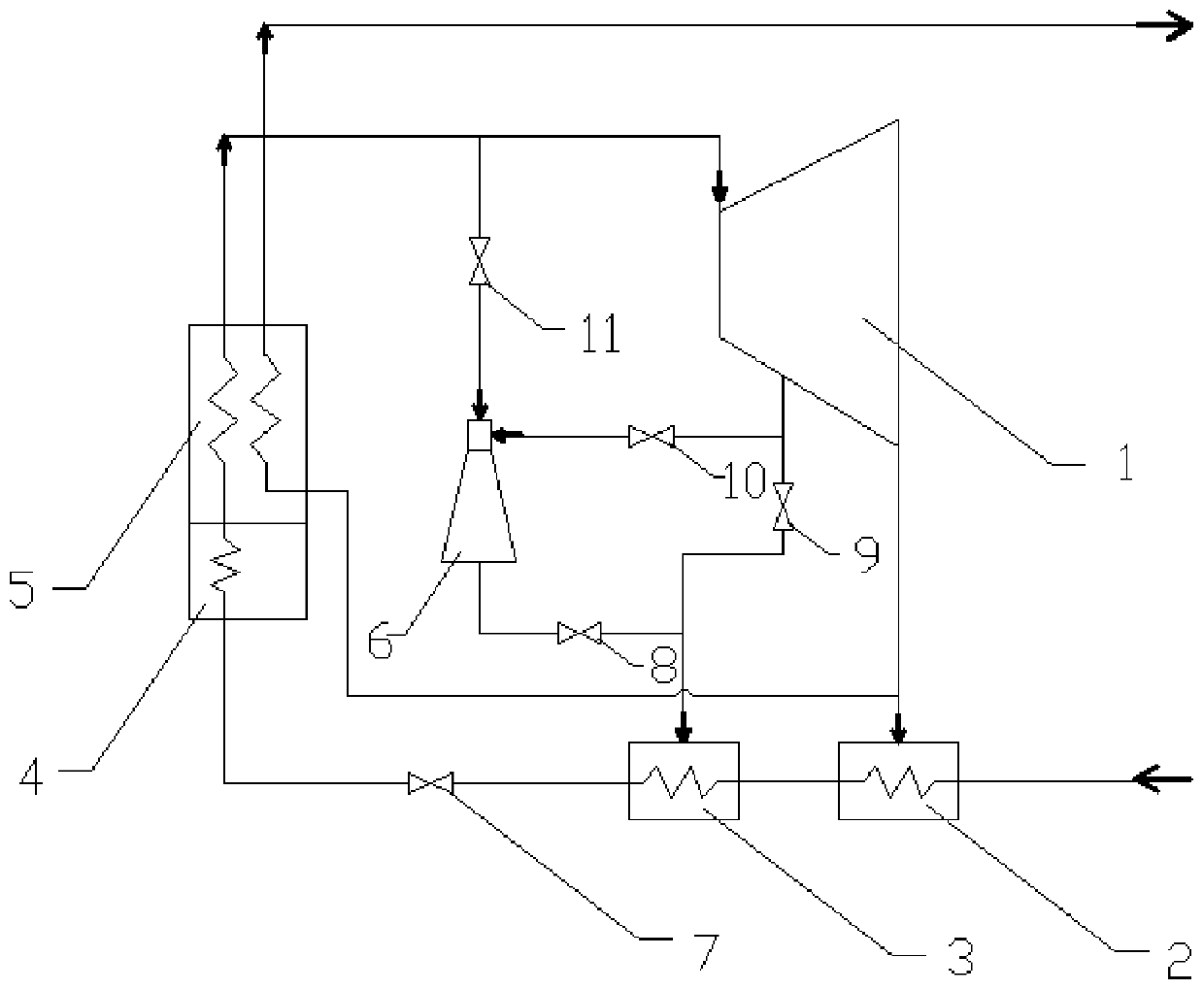

Method used

Image

Examples

Embodiment

[0029] A power plant is a 2×300MW subcritical direct air cooling unit. SCR denitration device is installed on the boiler flue gas system. The minimum load of the unit is 30%. When the operating load of the unit is greater than or equal to 70%, the SCR inlet flue gas temperature is greater than 290°C, and the SCR device can operate normally. When the operating load of the unit is less than 70%, the SCR inlet flue gas temperature is less than 290°C, and the SCR device cannot operate normally.

[0030] The steam booster system is connected in parallel on the steam extraction pipeline of the first stage of the high pressure cylinder. No. 1 extraction system and steam booster system share the same high-pressure heater. The two systems can be switched between high and low loads. When the unit is under high load, the original No. 1 steam extraction system operates, and the steam booster system is not put into operation; when the unit is under low load, the steam booster system op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com