A Method for Reconstructing Internal Defects of Three-pillar Insulators Based on the Principle of Ultrasonic Scanning

A technology for ultrasonic scanning and internal defects, which can be used in the processing of detection response signals, analysis of solids using sound waves/ultrasonic waves/infrasonic waves, and material analysis using sound waves/ultrasonic waves/infrasonic waves. Shape, bulky, defect visualization and other problems, to achieve the effect of intuitive identification and positioning and defect quantification, high detection accuracy and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

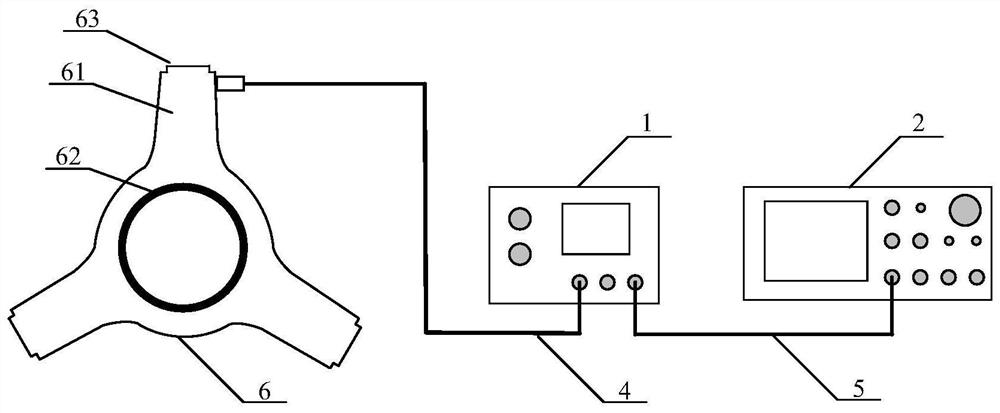

[0040] Such as figure 1 Shown is an ultrasonic testing system, including an ultrasonic pulse generator 1, an oscilloscope 2, a narrow pulse ultrasonic straight probe 3, a probe adapter line 4, and a high-impedance transmission line 5. The system detects a three-pillar insulator 6.

[0041] The three-post insulator 6 consists of a solid epoxy 61 , a center conductor 62 and a ground insert 63 . The solid epoxy part consists of three cylinders, each of which is combined with a grounding insert, and defects such as air gaps and shelling are most likely to occur at the joint between the grounding insert and the column foot. The central conductor is a ring-shaped structure made of aluminum. The size of the three-post insulator varies with the GIL voltage level.

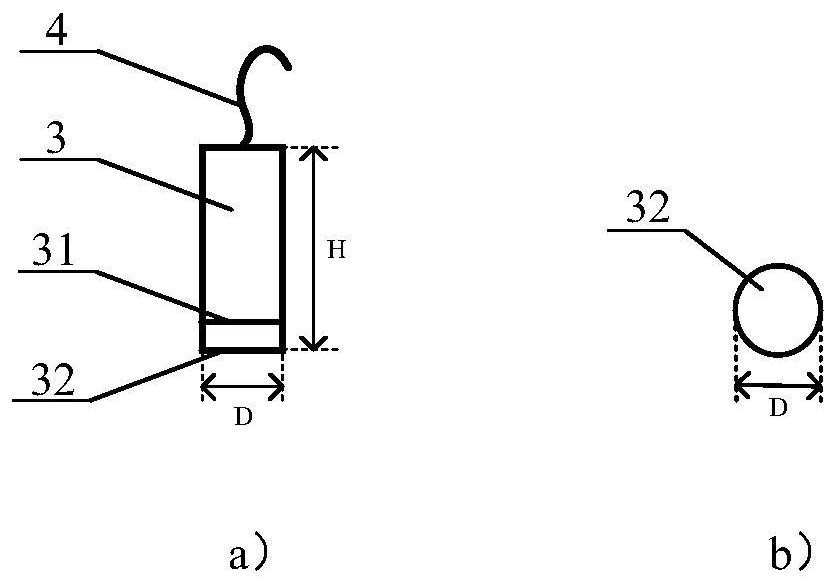

[0042] Such as figure 2 Shown is a schematic diagram of the structure of a narrow-pulse ultrasonic straight probe. The narrow-pulse ultrasonic straight probe adopts a circular composite piezoelectric chip, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com