Activated carbon composite material, preparation method and application thereof

A technology of composite materials and activated carbon, which is applied in the direction of chemical instruments and methods, alkali metal compounds, and other chemical processes, to achieve effective removal, good effect, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] This embodiment provides a kind of activated carbon composite material, is prepared by the following method:

[0086] 1) 28g of columnar activated carbon was placed in 500mL of ferrous sulfate solution with a concentration of 1mol / L and stirred for two hours;

[0087] 2) After cleaning the activated carbon particles obtained in step 1), put them in about 300mL of ultrapure water and stir them, and at the same time, add 100mL of potassium borohydride solution with a concentration of 1.08mol / L dropwise, and continue to stir for 24 hours after the dripping, and then dissolve the The prepared material was freeze-dried at -80°C for 8 hours in a freeze dryer to obtain the obtained product.

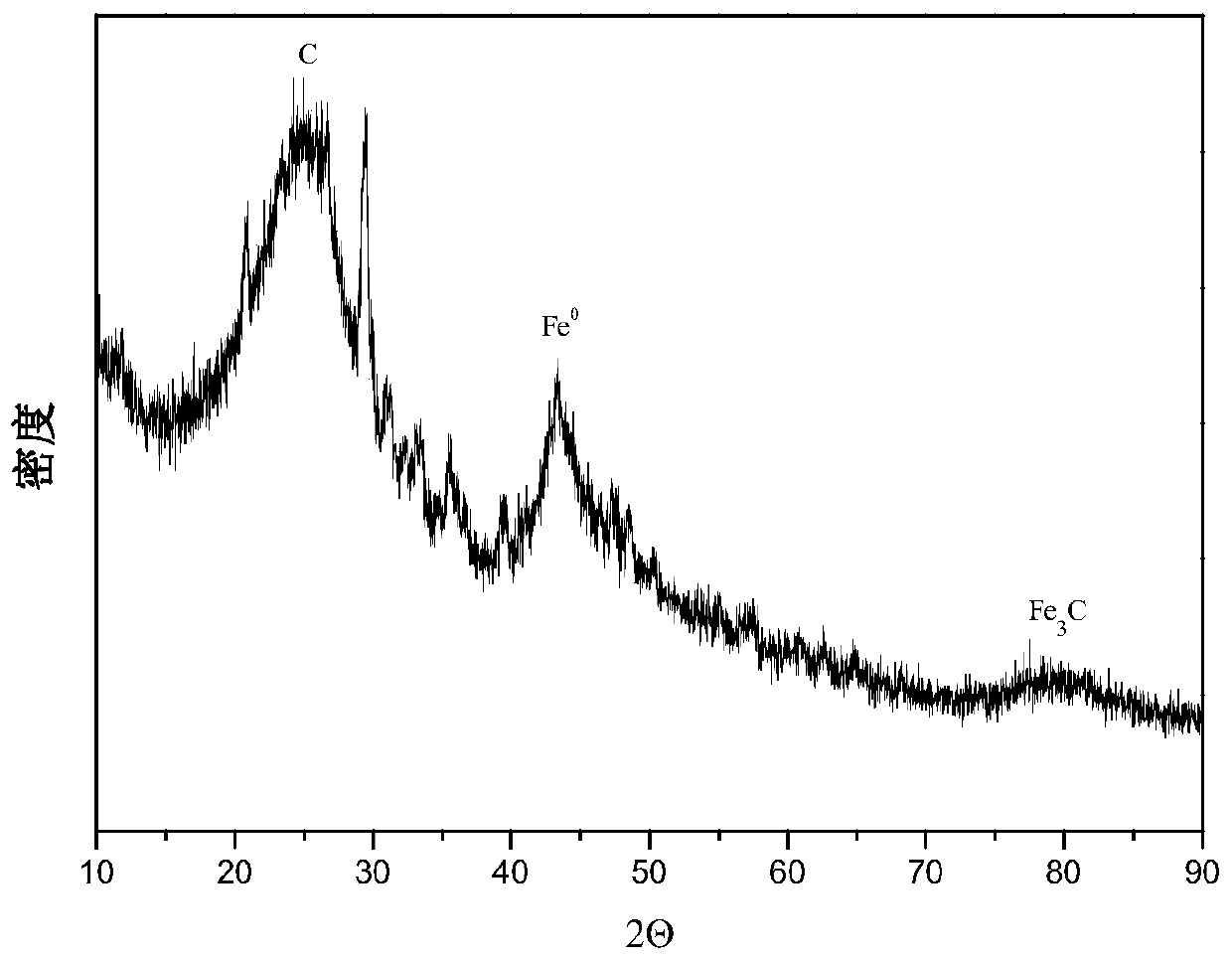

[0088] Characterized as Figure 1-1 to Figure 5 Shown:

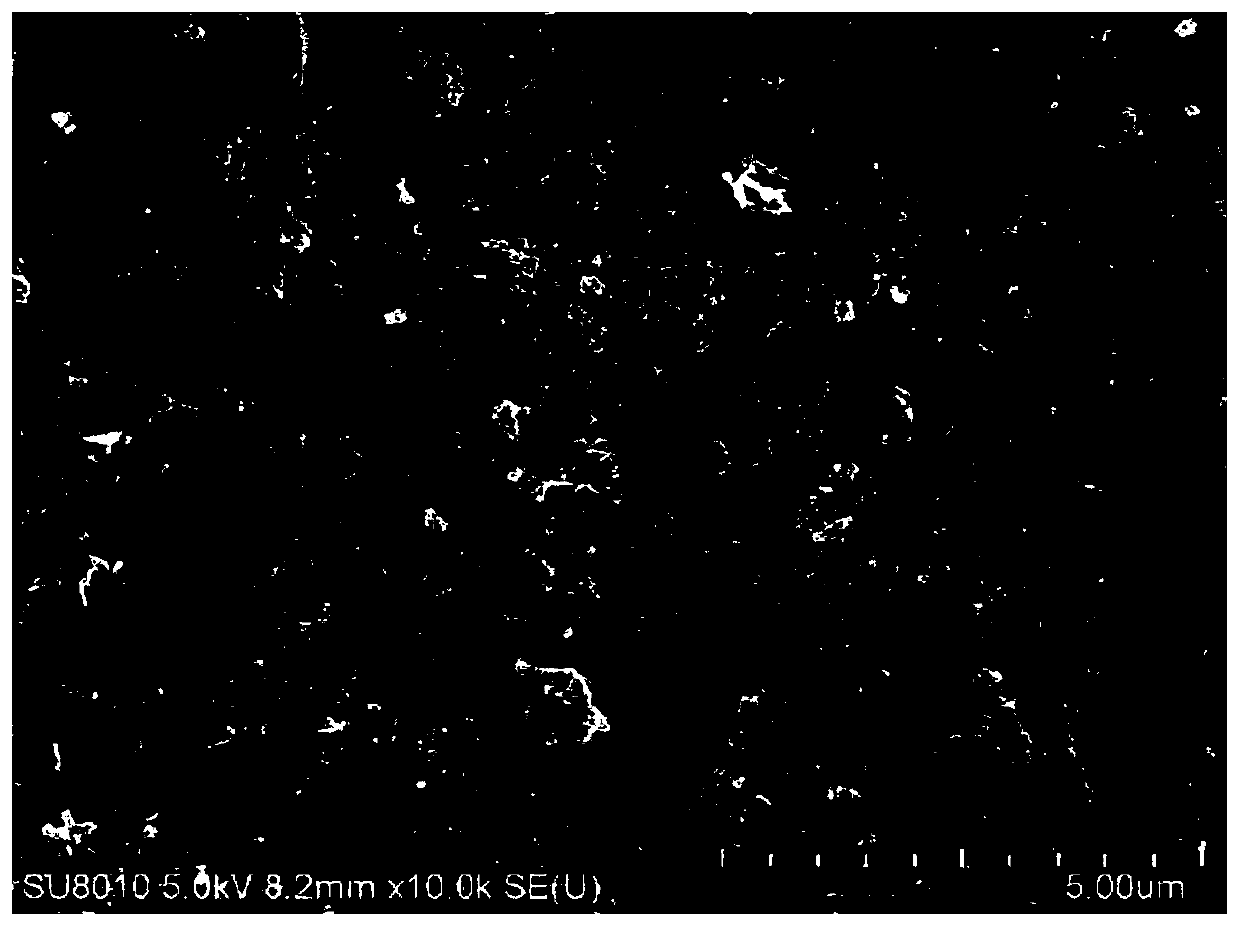

[0089] Reference attached Picture 1-1 And attached Figure 1-2 , is a scanning electron microscope image of the activated carbon composite material of the present invention, it can be seen that the surface of the activated carbo...

Embodiment 2

[0095] This embodiment provides a kind of activated carbon composite material, and the difference with embodiment 1 is:

[0096] The ratio of iron to carbon is 1:2.

Embodiment 3

[0098] This embodiment provides a kind of activated carbon composite material, and the difference with embodiment 1 is:

[0099] The ratio of iron to carbon is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com