Soil remediation agents and soil remediation methods

A soil remediation agent and soil technology, which is applied in the field of soil remediation agent and soil remediation, and can solve the problems of low curing efficiency and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

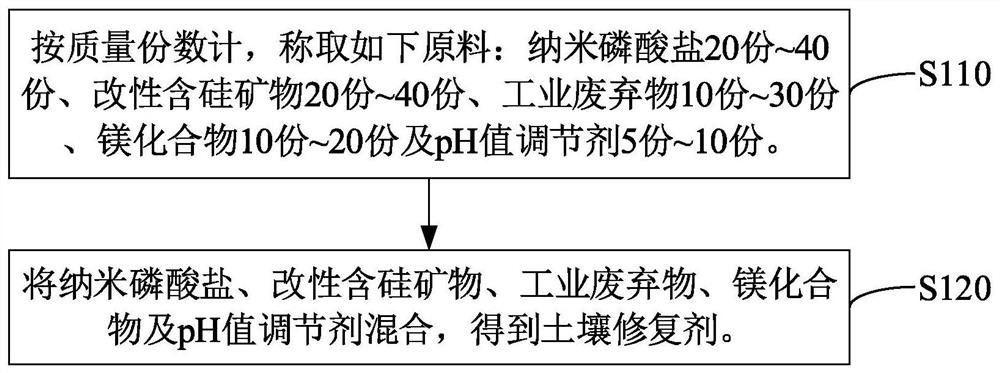

[0038] see figure 1 , the preparation method of the soil remediation agent of one embodiment, is a kind of preparation method of above-mentioned soil remediation agent, comprises the following steps:

[0039] Step S110: Weigh the following raw materials in parts by mass: 20-40 parts of nano-phosphate, 20-40 parts of modified silicon-containing minerals, 10-30 parts of industrial waste, 10-20 parts of magnesium compound And 5-10 parts of pH regulator.

[0040] Wherein, the preparation process of nano-phosphate comprises: adding the solution containing calcium source into ammonium hydrogen phosphate solution or phosphoric acid solution to obtain nano-phosphate. Specifically, the calcium source is selected from one of calcium hydroxide, calcium chloride and calcium nitrate. Further, after the step of adding the solution containing the calcium source into the ammonium hydrogen phosphate solution or the phosphoric acid solution, the steps of adjusting pH, stirring, standing for a...

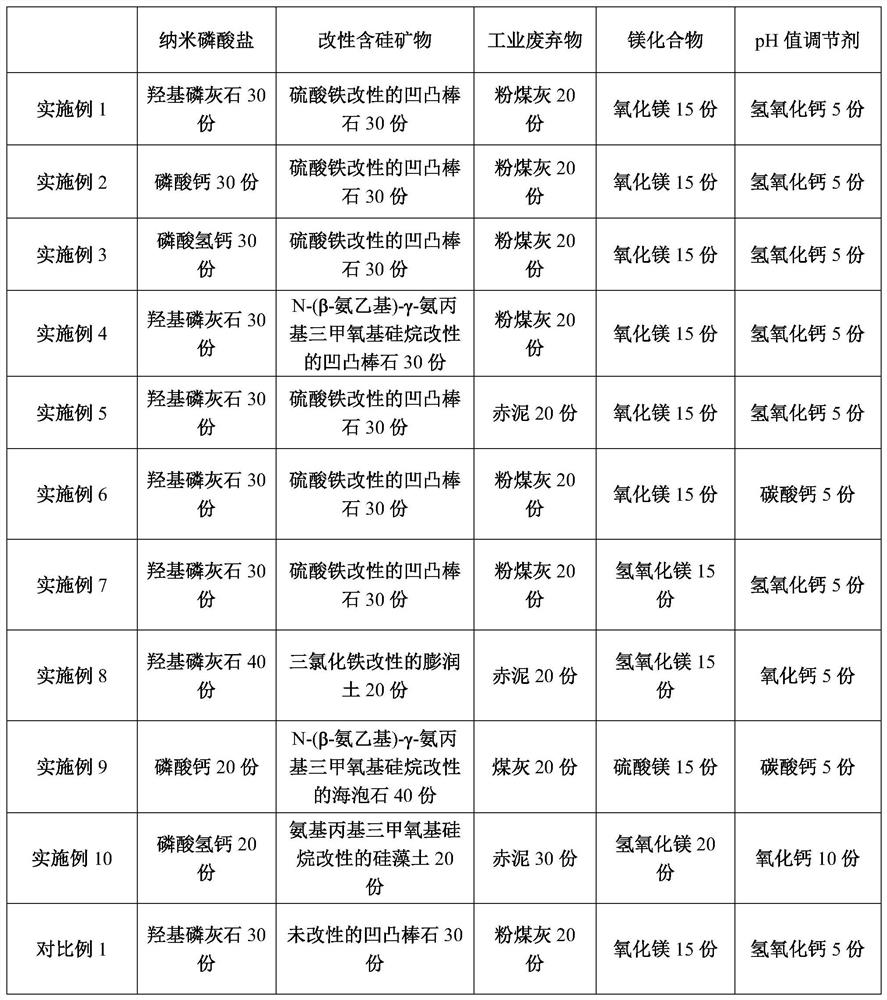

Embodiment 1

[0065] The preparation process of the soil remediation agent of the present embodiment is specifically as follows:

[0066] (1) Weigh 200 g of calcium hydroxide (industrial grade, calcium hydroxide content ≥ 96%) and place it in a 2000 mL beaker, add 1000 mL of deionized water, and stir magnetically to form a uniform solution. Measure 100mL of industrial-grade phosphoric acid solution (phosphoric acid content ≥ 85%) and place it in a 5000mL beaker, add 1000mL of deionized water to dilute the phosphoric acid, control the dropping rate to 30mL / min, and add the uniform solution dropwise to the diluted phosphoric acid solution In the process, the pH value of the reaction was controlled at 10-12 by adding ammonia water dropwise, then stirred at 160r / min and reacted at room temperature for 4 hours, and then left to age for 2 hours. After collecting the supernatant, the precipitate was filtered and washed twice. After drying, the obtained product is nano-hydroxyapatite.

[0067] (2)...

Embodiment 2

[0070] The preparation process of the soil remediation agent of the present embodiment is specifically as follows:

[0071](1) Weigh 200 g of calcium hydroxide (industrial grade, calcium hydroxide content ≥ 96%) and place it in a 2000 mL beaker, add 1000 mL of deionized water, and stir magnetically to form a uniform solution. Measure 106.5mL of 85% industrial-grade phosphoric acid solution in a 5000mL beaker, add 1000mL deionized water to dilute the phosphoric acid, control the rate of addition to 30mL / min, add the uniform solution dropwise to the diluted phosphoric acid solution, and Add ammonia water to control the reaction pH value at 6-8, then react at room temperature for 4 hours with stirring at 160r / min, and then let it stand and age for 2 hours. After collecting the supernatant, filter the precipitate, wash it twice, and dry it to obtain the product It is nano calcium phosphate.

[0072] (2) Weigh 10g of ferric sulfate and place it in a 1000mL beaker, add 500mL of dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com