A degradable self-repairing water-retaining and sand-fixing agent and its preparation method

A sand-fixing agent and self-repairing technology, applied in chemical instruments and methods, other chemical processes, agriculture, etc., can solve the problems of chemical sand-fixing agents being difficult to degrade, pollution in desert areas, etc., achieving good sand-fixing effect, long-term sand-fixing time, wide Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

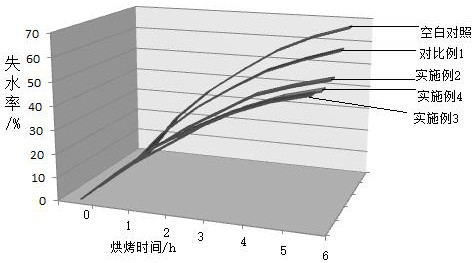

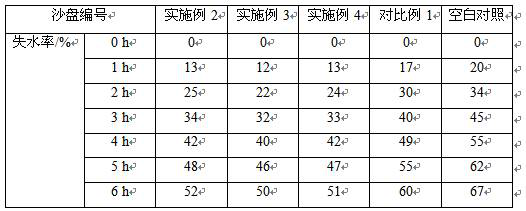

Examples

Embodiment 1

[0022] Step 1, a hydrogel: 10 parts by weight of acrylamide, 3 parts of yellow gum, 10 parts of acrylic, 100 parts of water, add 0.5% of the mixture of 0.5% to potassium sulfate, add 0.3%. Unitedial age N, N'-methylene bis acrylamide, stirred for 20 min to give hydrogel to be used;

[0023] Step 2, a microcapsule is prepared: mixing the aqueous polyurethane powder and the stearate ratio of 100: 5, and the vortex gas flow refinement machine rotational speed 300 rpm is treated, and the stearic acid is sufficiently encapsulated with aqueous polyurethane powder, and then the mass concentration is 8 % Of the germinated starch, refined the mass ratio of the modified waterborne polyurethane powder and the germinated starch fluid of 3: 2; spray drying at 100 ° C, i.e., microcapsules to be used;

[0024] Step 3, preparing degradable self-repairing watergaining agent: 30 parts by weight of the hydrogel in step one, 5 parts by weight of the microcapsules in step two, 5 parts by weight of the...

Embodiment 2

[0026] Step 1, preparing a hydrogel: 15 parts of the weight of the acrylamide, 5 parts of xanthan gum, 8 parts of acrylic, 110 parts of water, add 0.5% of the mixture of 0.5% to potassium sulfate, add 0.3%. UNDER N, N'-methylene biscrylamide, stirring at least 10 min to give hydrogel to be used;

[0027] Step 2, a microcapsule is prepared: mixing the aqueous polyurethane powder and the stearate ratio of 100: 5, and the vortex gas flow refinement machine rotational speed 300 rpm is treated, and the stearic acid is sufficiently encapsulated with aqueous polyurethane powder, and then the mass concentration is 8 % Of the germinated starch, refined the mass ratio of the modified waterborne polyurethane powder and the germinated starch fluid of 3: 2; spray drying at 100 ° C, i.e., microcapsules to be used;

[0028] Step 3, preparing degradable self-repairing water saffodil: 30 parts by weight of the hydrogel in step one, 8 parts by weight of the microcapsules in step second, 5 parts by ...

Embodiment 3

[0030] Step 1, a hydrogel: 15 parts of the weight of the acrylamide, 5 parts of xanthan gum, 10 parts of acrylic, 150 parts of water, add 0.5% of the mixture of 0.5% to potassium sulfate, add 0.3%. UNDER N, N'-methylene biscrylamide, stirring at least 10 min to give hydrogel to be used;

[0031] Step 2, microcapsules: mixing the aqueous polyurethane powder and the stearate mass ratio of 100: 5, treated with vortex gas generator rotational speed 500 rpm, so that the stearic acid is sufficiently wrapped in aqueous polyurethane powder, and then the mass concentration is 8 % Of the germinated starch, refined the mass ratio of the modified waterborne polyurethane powder and the germinated starch fluid of 3: 2; spray drying at 100 ° C, i.e., microcapsules to be used;

[0032] Step three, preparing degradable self-repairing watergaining agent: 25 parts by weight of the hydrogel in step one, 9 parts by weight of the microcapsules in step second, 3 parts by weight of zeolite powder, to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com