Double layer overpressure resistant cabin body of great depth underwater vehicle and molding method thereof

A technology for underwater vehicles and pressure chambers, applied to underwater ships, underwater operating equipment, coatings, etc., can solve problems such as anti-corrosion problems, achieve excellent seawater resistance, increase strength and stiffness, and good insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

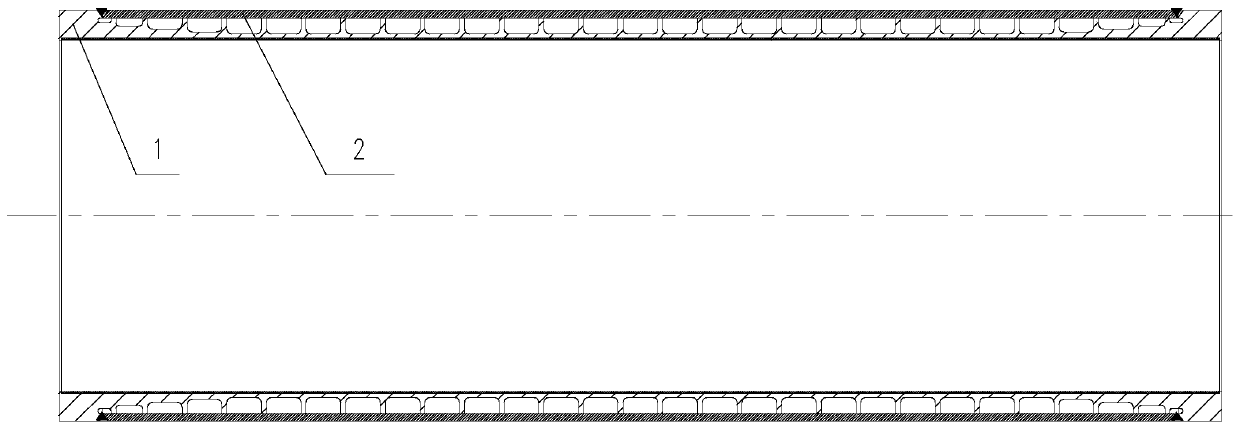

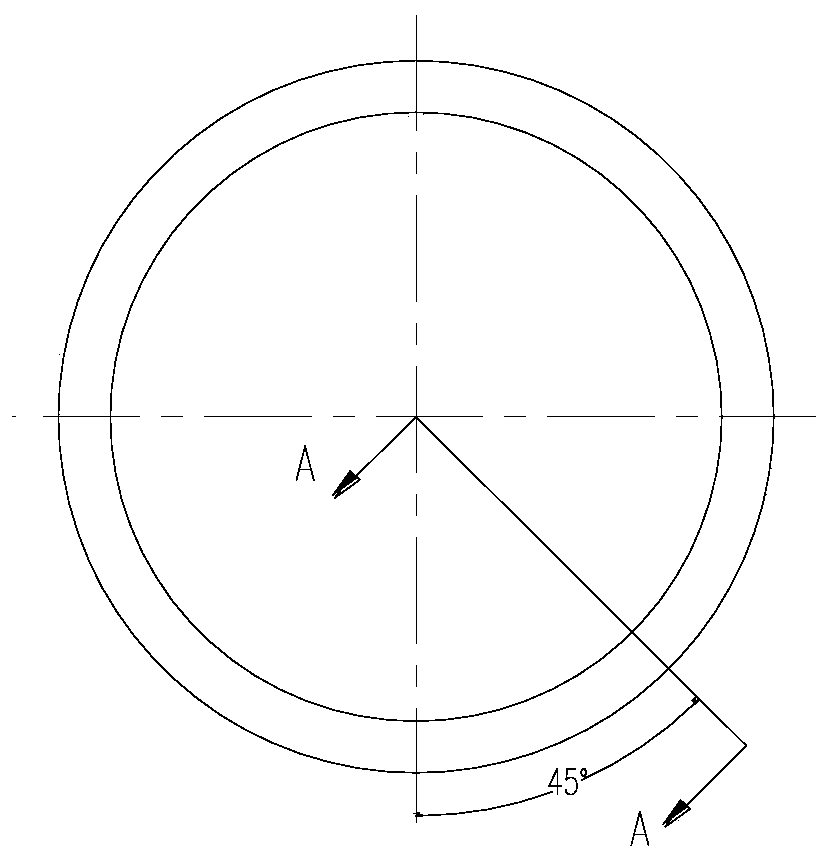

[0089] Step 1. Processing the inner shell and the ring rib on the inner shell requires the first machining allowance to be left on the outer surface and inner surface of the inner shell respectively;

[0090] Preferably, the inner shell is made of a thick-walled extruded tube as a blank, and the ring rib of the inner shell is processed to a preset size by mainly using a turning machining process;

[0091] Preferably, the first machining allowance is 3mm; preferably, the inner shell is 7A05 aluminum alloy;

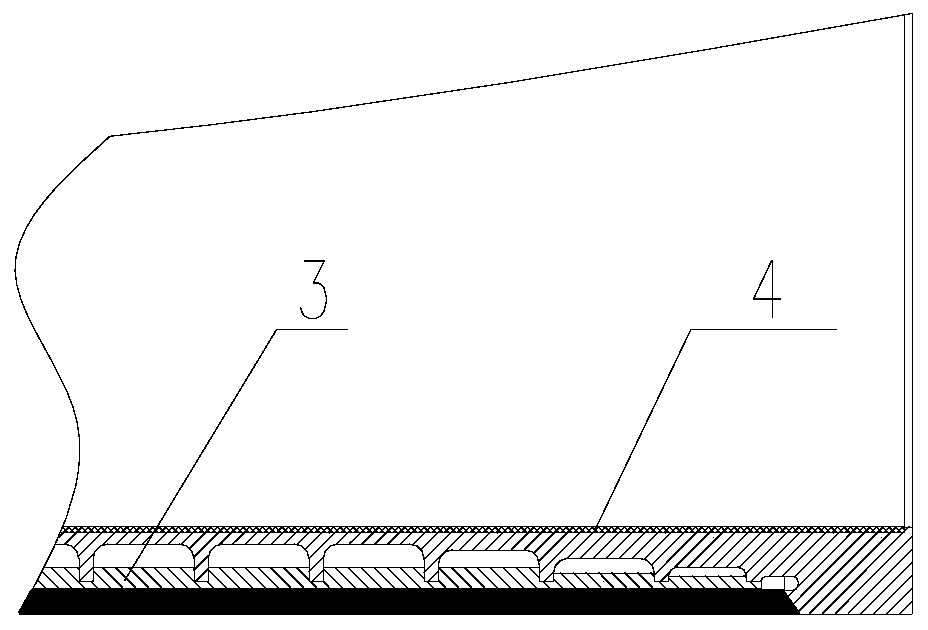

[0092] Step 2, processing and installing the groove of the longitudinal weld backing plate 3 on the ring rib of the inner shell, and installing the longitudinal weld backing plate 3 on the ring rib of the inner shell;

[0093] Step 3. The shell is rolled into a circle with a plate 4mm thicker than the preset wall thickness, and the longitudinal weld after the circle is formed by friction stir welding;

[0094] Preferably, the shell is made of 5A06 aluminum alloy;

[0095]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com