Biomass modification system for sludge dewatering and working method thereof

A sludge dehydration and working method technology, applied in the direction of dehydration/drying/concentrated sludge treatment, grain treatment, etc., can solve the problems of lack of reasonable and effective utilization methods, complicated process, difficult to degrade, etc., and achieve reasonable and effective utilization methods, Solve environmental pollution and improve dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

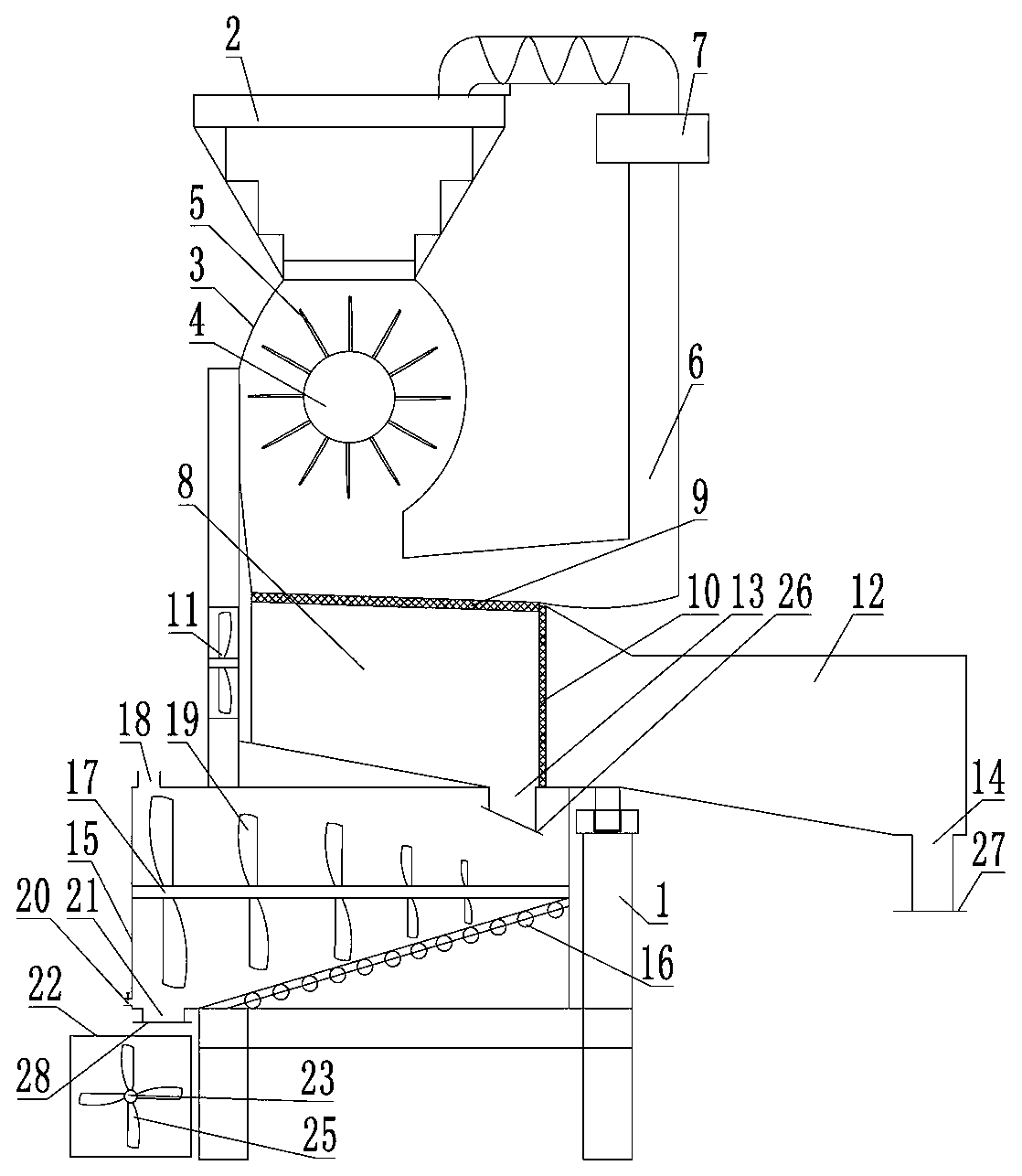

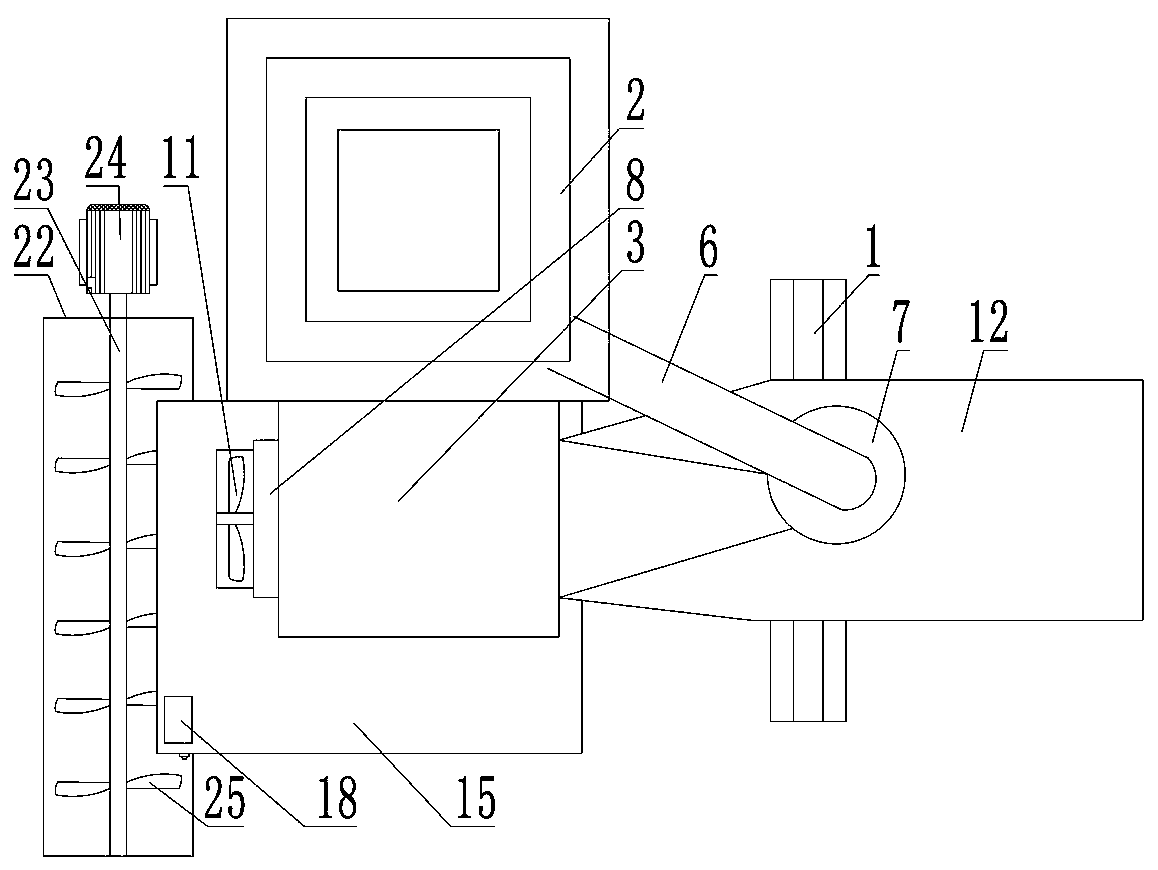

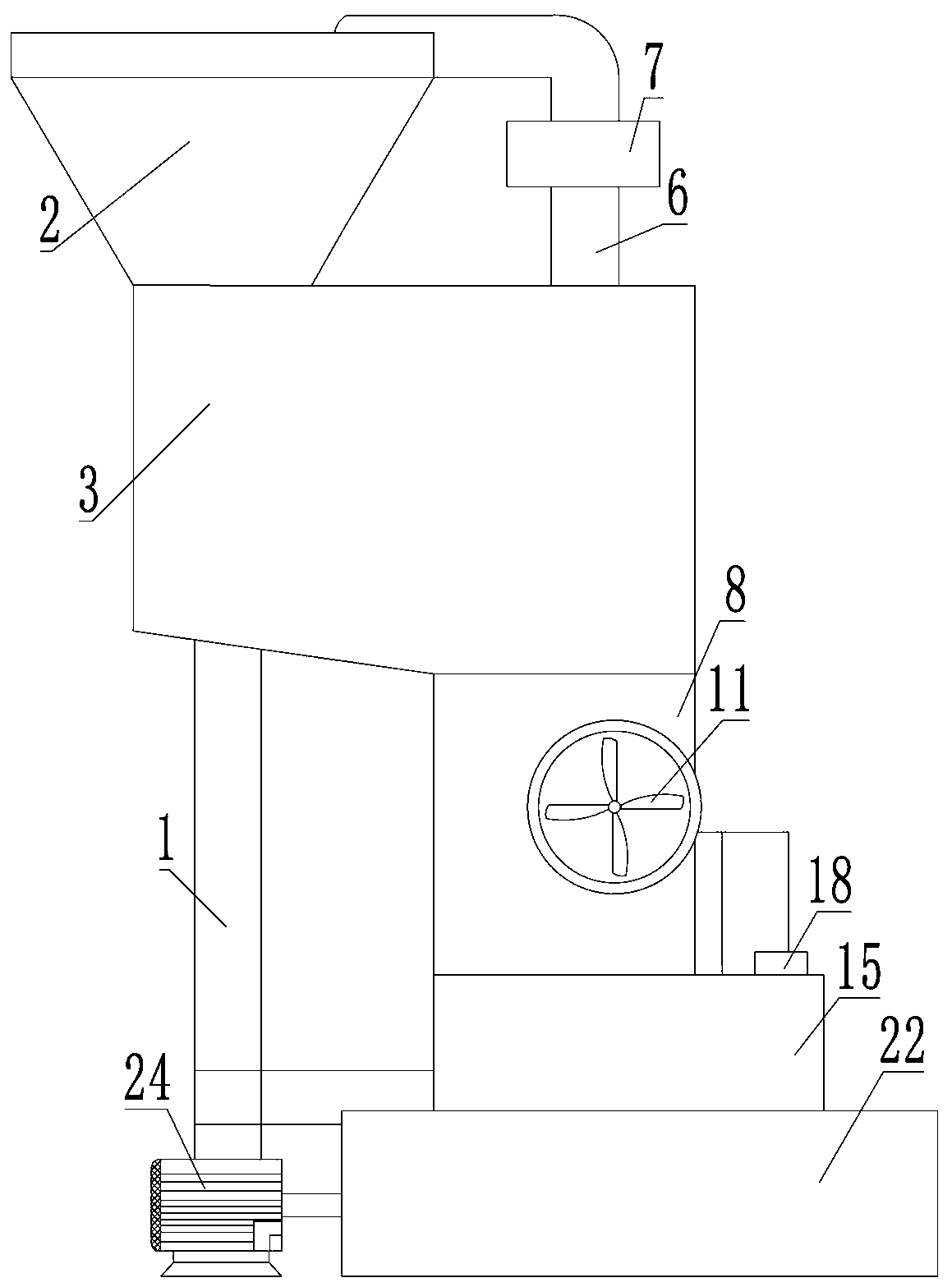

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-Figure 6 As shown, the biomass modification system for sludge dewatering includes a frame 1, and the frame 1 is sequentially provided with a crushing mechanism, a screening mechanism and a modification mechanism from top to bottom, and a machine located below the modification mechanism is arranged. The mixing mechanism on one side of frame 1; the bottom outlet of the crushing mechanism is connected to the top inlet of the screening mechanism, and the coarse material outlet at the bottom of the screening mechanism is connected to the feeding inlet on the top of the modification mechanism. The fine material discharge port on the side of the mechanism is connected to the collection bin 12, and the discharge port at the bottom of the modification mechanism is connected to the feed port at the top of the mixing mechanism.

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com