Preparation method of cellulose whisker composite modified TPU cast film

A cellulose whisker and compound modification technology, applied in the field of new materials, can solve the problems of general and unsatisfactory tensile properties of TPU cast film, and achieve the goals of reducing water vapor transmission coefficient, strengthening force and promoting crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

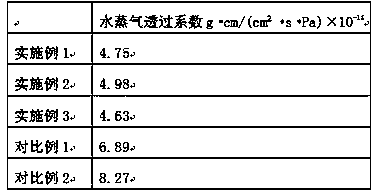

Embodiment 1

[0019] A preparation method of cellulose whisker composite modified TPU cast film, the particle microrods, cellulose whiskers are uniformly mixed with TPU particles in a twin-screw extruder under the promotion of coupling agent kh-540, After vacuum drying, the casting film is prepared by casting equipment;

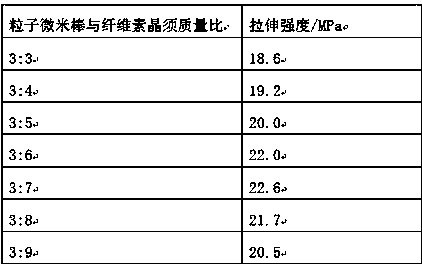

[0020] The mass ratio of the particle microrods to the cellulose whiskers is 3:6;

[0021] The mass ratio of the particle microrods to the coupling agent is 10:1;

[0022] The mass ratio of the particle microrods to the TPU particles is 1:70.

[0023] As a further solution, the method for preparing particle microrods includes the following steps:

[0024] Add 1 part of citric acid to 20 parts of ethanol solution in parts by weight, stir at 30°C for 15 minutes at a speed of 120r / min to obtain a mixed solution, add 5 parts of ethyl orthosilicate, 0.2 One part of hexamethylcyclotrisilazane and 9 parts of ammoniacal liquor, wherein the ammoniacal liquor was added dropwise, ...

Embodiment 2

[0032] A preparation method of cellulose whisker composite modified TPU cast film, the particle microrods, cellulose whiskers are uniformly mixed with TPU particles in a twin-screw extruder under the promotion of coupling agent kh-540, After vacuum drying, the casting film is prepared by casting equipment;

[0033] The mass ratio of the particle microrods to the cellulose whiskers is 3: 8;

[0034] The mass ratio of the particle microrods to the coupling agent is 10:1;

[0035] The mass ratio of the particle microrods to the TPU particles is 1:75.

[0036] As a further solution, the method for preparing particle microrods includes the following steps:

[0037] Add 1.2 parts of citric acid to 20 parts of ethanol solution in parts by weight, stir at 30°C for 20 minutes at a speed of 120r / min to obtain a mixed solution, add 5 parts of ethyl orthosilicate, 0.2 One part of hexamethylcyclotrisilazane and 9 parts of ammoniacal liquor, wherein the ammoniacal liquor was added dropwi...

Embodiment 3

[0045] A preparation method of cellulose whisker composite modified TPU cast film, the particle microrods, cellulose whiskers are uniformly mixed with TPU particles in a twin-screw extruder under the promotion of coupling agent kh-540, After vacuum drying, the casting film is prepared by casting equipment;

[0046] The mass ratio of the particle microrods to the cellulose whiskers is 3:7;

[0047] The mass ratio of the particle microrods to the coupling agent is 10:1;

[0048] The mass ratio of the particle microrods to the TPU particles is 1:72.

[0049] As a further solution, the method for preparing particle microrods includes the following steps:

[0050]Add 1.1 parts of citric acid to 20 parts of ethanol solution in parts by weight, stir at 30°C at a speed of 120r / min for 18min to obtain a mixed solution, add 5 parts of ethyl orthosilicate, 0.2 One part of hexamethylcyclotrisilazane and 9 parts of ammoniacal liquor, wherein the ammoniacal liquor was added dropwise, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com