Double crosslinked hydrogel based on calcium peroxide/polymer oxygen generating particles and preparation method of hydrogel

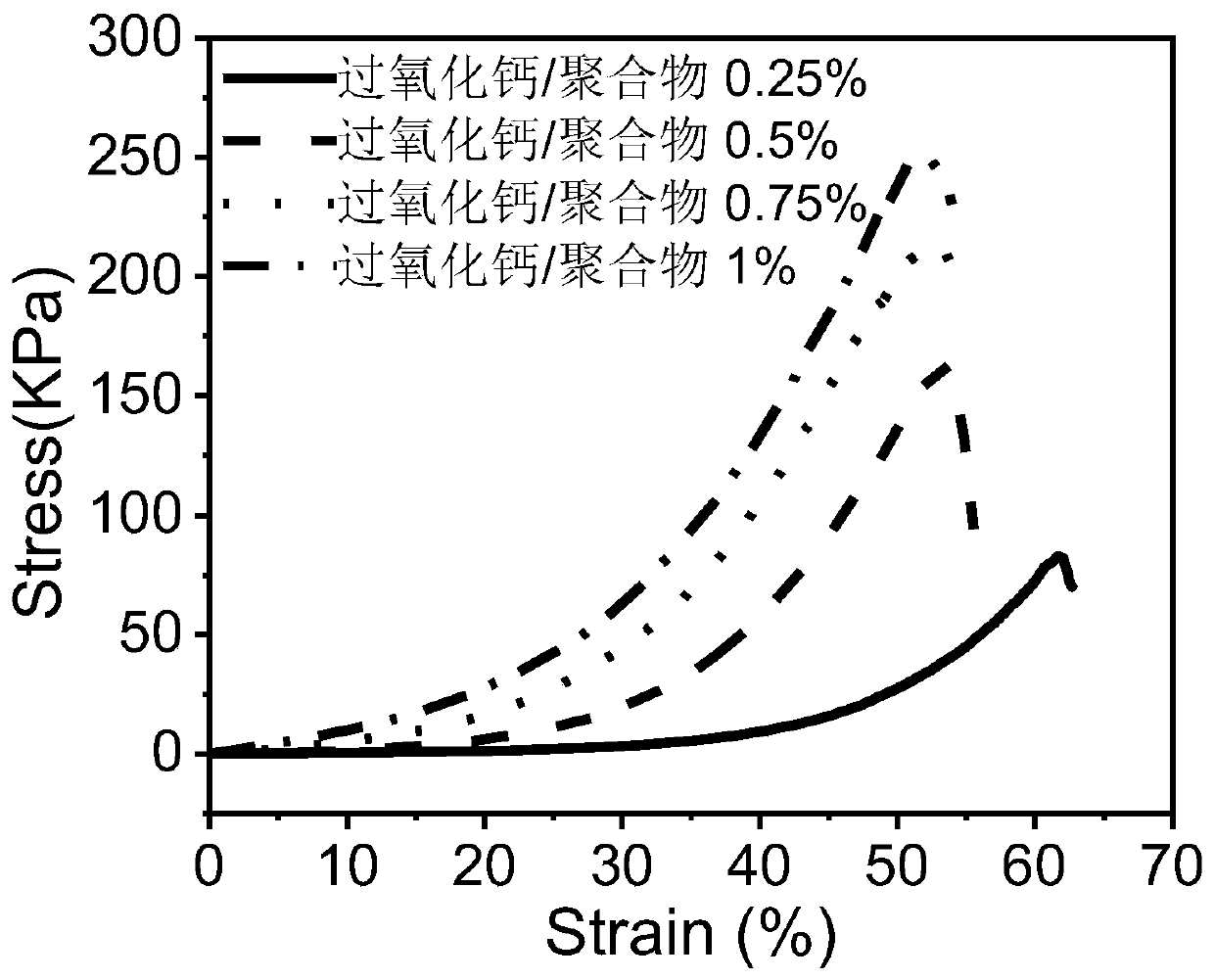

A calcium peroxide and polymer technology, applied in the field of medical biomaterials, can solve problems such as inconvenient use, insufficient mechanical strength, and short oxygen production time, and achieve the effect of slowing down the reaction and increasing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

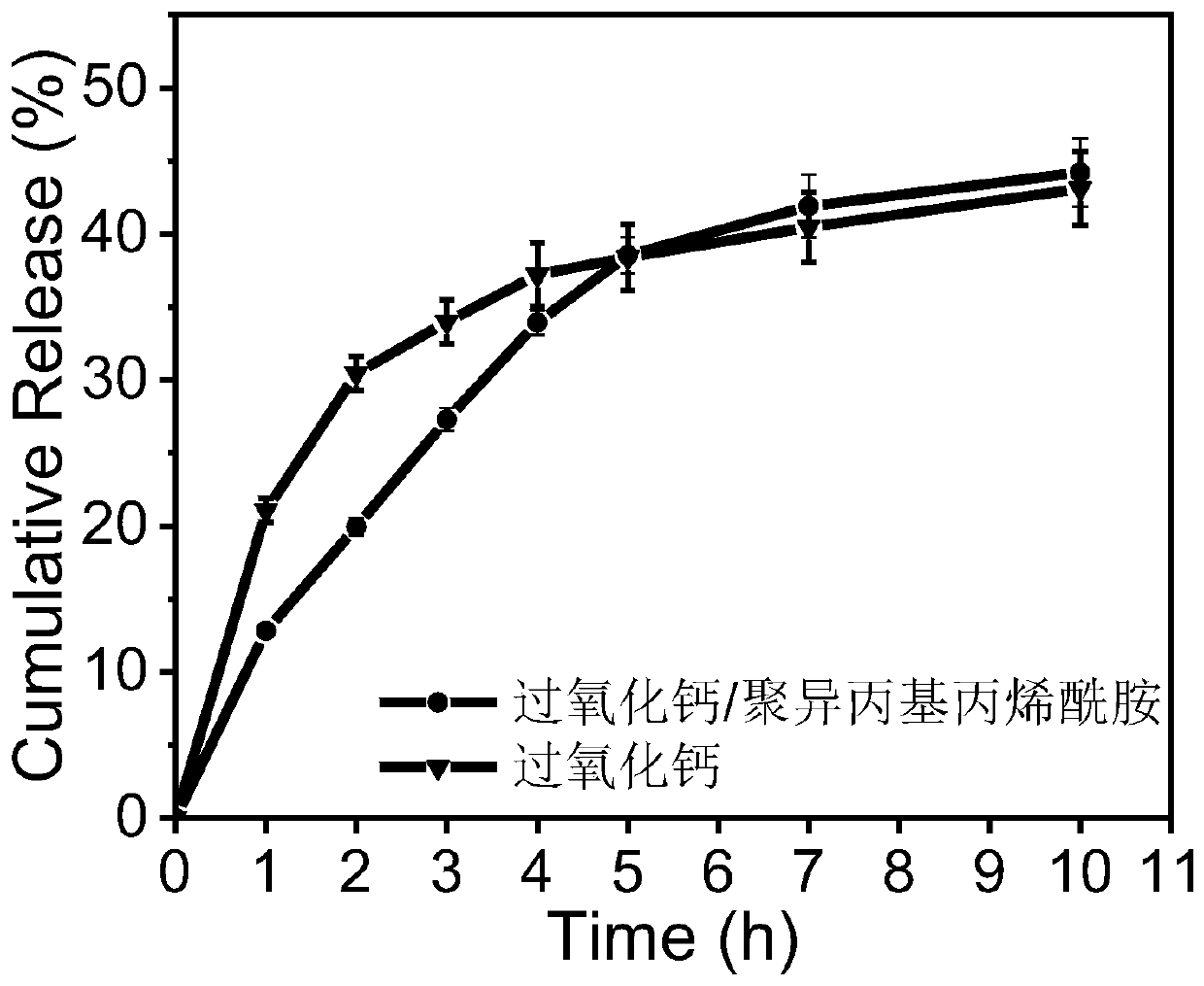

[0029] Example 1: Preparation of calcium peroxide / polyisopropylacrylamide oxygen-generating particles

[0030]Weigh 3g of anhydrous calcium chloride, dissolve 6g of polyisoacrylacrylamide in 130mL of deionized water, stir until it is completely dissolved, then add 15mL of 25% ammonia water to the mixed solution, stir for 1 hour, and then add 20mL of 30% hydrogen peroxide was added dropwise into the reaction solution, and the stirring speed was 100 r / min. After reacting at room temperature for 4 hours, then add 0.1mol / L sodium hydroxide solution until the pH value of the solution reaches 11, centrifuge at a speed of 1000r / min for 5 minutes to separate the precipitate, wash the resulting precipitate with alkali three times, and then use The precipitate was washed with deionized water until the pH of the filtrate was 8.0. Then vacuum-dry at 45° C. for 48 hours to obtain calcium peroxide / polyisopropylacrylamide oxygen-generating particles.

Embodiment 2

[0031] Example 2: Preparation of calcium peroxide / polycaprolactam oxygen-generating particles

[0032] Weigh 3g of anhydrous calcium chloride, dissolve 30g of polycaprolactam in 130mL of deionized water, stir until it is completely dissolved, then add 15mL of 25% concentrated ammonia water to the mixed solution, stir for 2 hours, and then add 20mL of 30% polycaprolactam Hydrogen peroxide was added dropwise into the reaction solution, and the stirring speed was 500r / min. After reacting at room temperature for 6 hours, then add 0.1mol / L sodium hydroxide solution until the pH value of the solution reaches 11.5, centrifuge at a speed of 5000r / min for 5 minutes to separate the precipitate, wash the resulting precipitate with alkali three times, and then use The precipitate was washed with deionized water until the pH of the filtrate was 8.5. Then vacuum-dry at 50° C. for 36 hours to obtain calcium peroxide / polycaprolactam oxygen-generating particles.

Embodiment 3

[0033] Example 3: Preparation of Calcium Peroxide / Polyethylene Glycol Oxygen Particles

[0034] Weigh 3g of anhydrous calcium chloride, dissolve 60g of polyethylene glycol in 130mL of deionized water, stir until it is completely dissolved, then add 15mL of 25% concentrated ammonia water into the mixed solution, stir for 4 hours, and then add 20mL of 20mL with a mass fraction of 30 % hydrogen peroxide was added dropwise into the reaction solution, and the stirring speed was 1000r / min. After reacting at room temperature for 8 hours, add 0.1mol / L sodium hydroxide solution until the pH value of the solution reaches 12, centrifuge at a speed of 10000r / min for 5 minutes to separate the precipitate, wash the obtained precipitate with alkali three times, and then use deionized The precipitate was washed with water until the pH of the filtrate was 9. Then vacuum-dry at 60° C. for 24 hours to obtain calcium peroxide / polyethylene glycol oxygen-generating particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com