Insulated electric wire, production method therefor, coil and coil production method using same

A technology of insulated wires and insulating coatings, applied in the direction of insulated cables, cable/conductor manufacturing, inductor/transformer/magnet manufacturing, etc., which can solve the problems of poor insulation or heat resistance, insufficient adhesion, and high manufacturing costs. Problems, to achieve the effect of excellent insulation properties or heat resistance, excellent adhesion, and maintain hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Next, examples of the present invention will be described in detail together with comparative examples.

[0067]

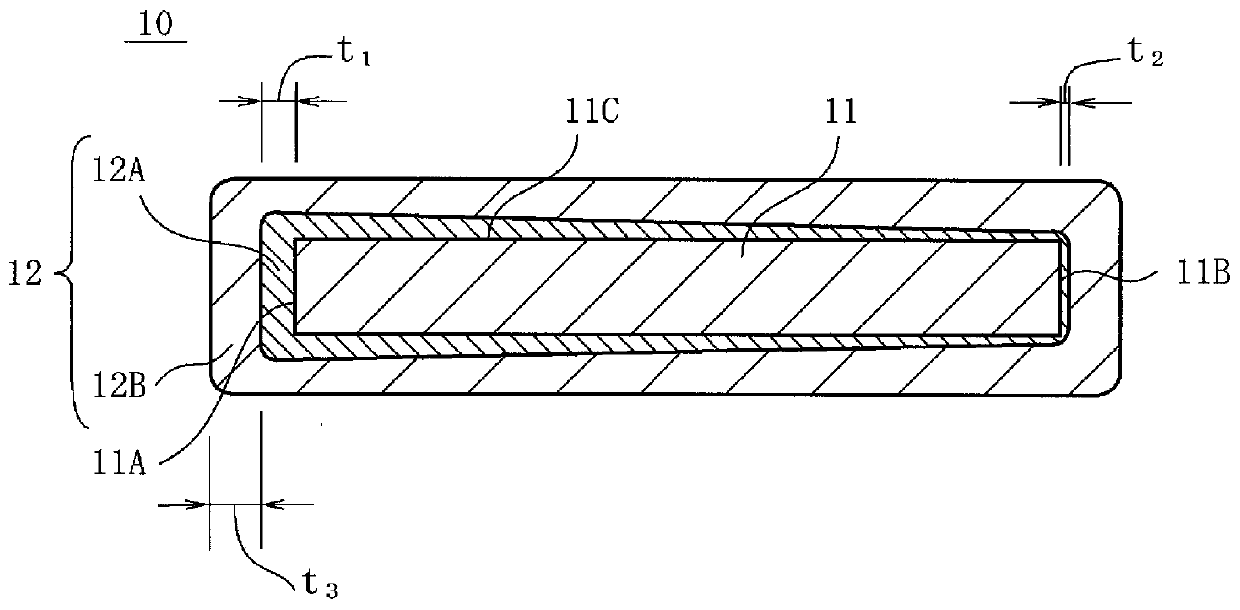

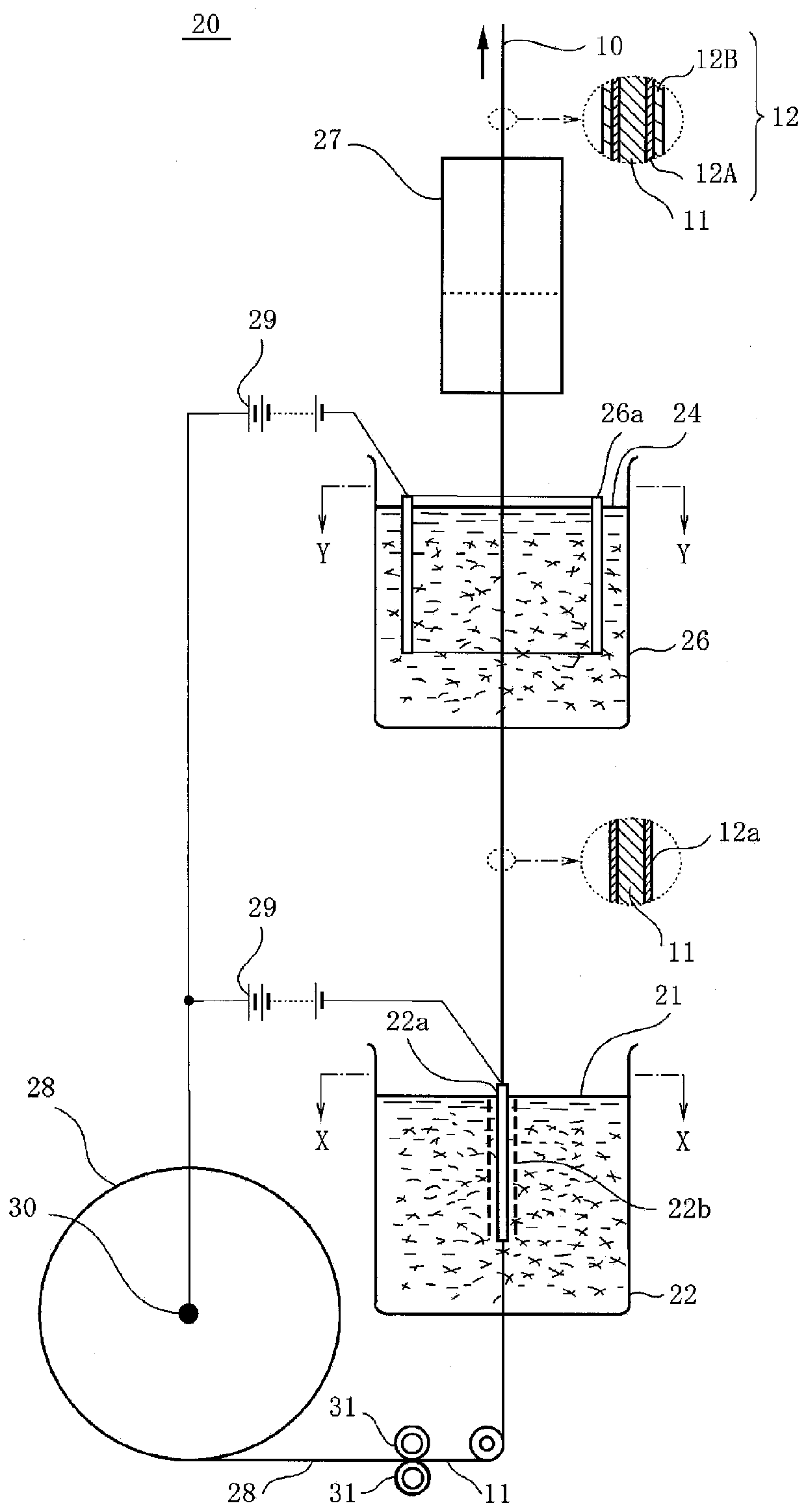

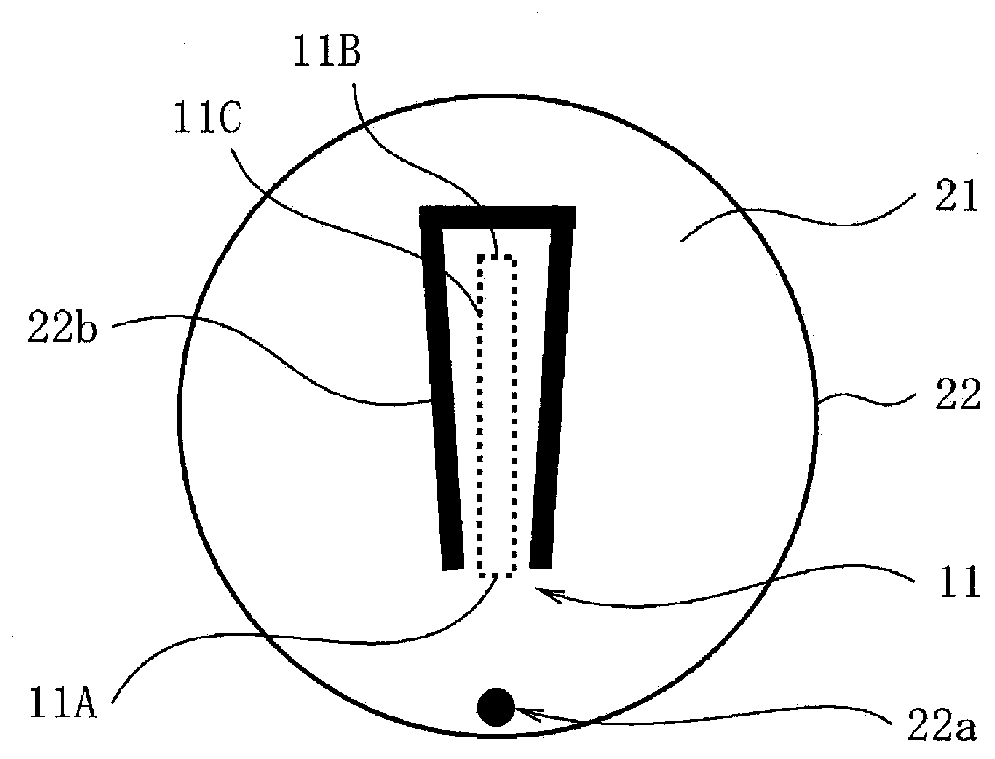

[0068] pass figure 2 In the illustrated electrodeposition coating apparatus, an insulating coating is applied to a flat copper wire having a thickness of 1.5 mm and a width of 6.5 mm as a conductor wire. As the first electrodeposition solution, a water-dispersed insulating electrodeposition paint containing polyamideimide (PAI) having a urethane skeleton of 2% by mass was prepared and stored in the first electrodeposition tank. In addition, a water-dispersed insulating electrodeposition paint containing 2% by mass of PAI was prepared as a second electrodeposition solution, and stored in a second electrodeposition tank. Such as image 3 As shown, a cathode rod is configured in the first electrodeposition tank, such as Figure 4 As shown, a semicylindrical cathode plate is disposed in the second electrodeposition tank. Such as image 3 and Figure 4 ...

Embodiment 2~6

[0070]

[0071] In addition to changing the main components of the first and second electrodeposition solutions, the long side / short side of the flat conductor wire, the diameter of the flat conductor wire converted to a round wire, and the manufacturing conditions of the insulated wire, as shown in Table 1 Outside In the same manner as in Example 1, insulated electric wires of Examples 2 to 6 and Comparative Examples 1 to 3 were produced. In Example 4, an insulated wire was produced using a water-dispersed insulating electrodeposition paint containing PI having a siloxane skeleton as the first electrodeposition liquid. In addition, in Comparative Examples 1 to 3, the flat conductor wire was not passed through the first electrodeposition solution, but only the second electrodeposition solution was passed to manufacture an insulated wire. At this time, the electrodeposition tank is as follows Figure 5 As shown, it is circular in plan view, and a cylindrical cathode plate 36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com