Method for preparing zinc oxalate through zinc oxide dust and method for preparing nanometer zinc oxide

A technology of zinc oxalate and zinc oxide, applied in the directions of zinc oxide/zinc hydroxide, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of inability to realize iron recycling, complicated production operation, high production cost, and achieve recycling The effect of high added value of products, simple process and high efficiency recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

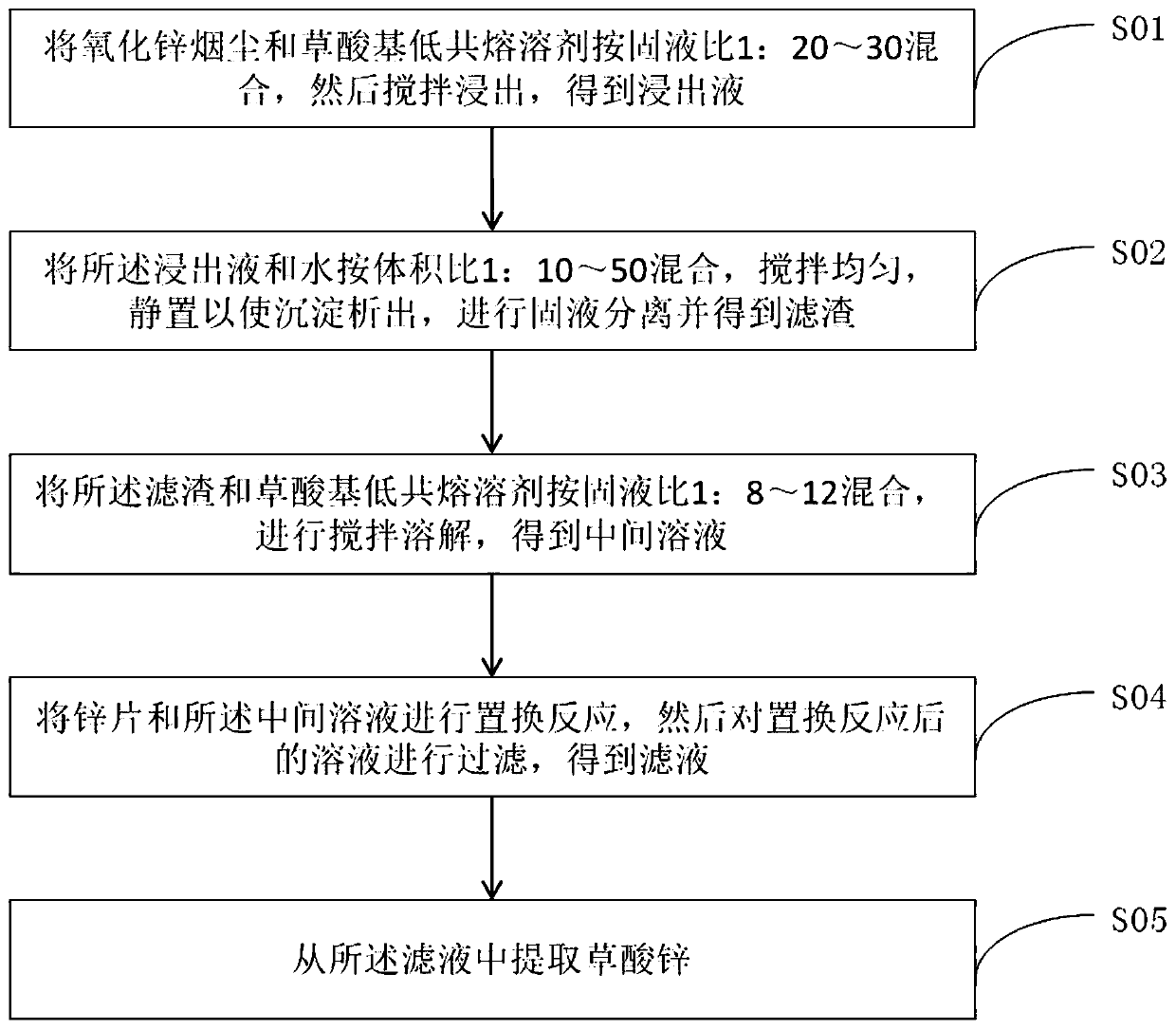

[0039] (1) Prepare quaternary ammonium salt and oxalic acid according to the molar ratio of 1:1 to make oxalic acid-based deep eutectic solvent.

[0040] (2) Add zinc oxide dust (51% zinc content) into the deep eutectic solvent prepared in step (1) according to the solid-to-liquid ratio of 1:20, stir and leaching at 50°C for 6 hours, and pour into the leaching solution Add distilled water, wherein the volume ratio of leachate and distilled water is 1:10, stir evenly and let it stand for 10 minutes, and obtain a filter residue rich in zinc oxalate through solid-liquid separation.

[0041] (3) Add the zinc oxalate-rich filter residue obtained in step (2) to the newly configured oxalic acid-based deep eutectic solvent at a ratio of 1:10, stir and dissolve at a temperature of 70°C for 2 hours, and then dissolve it at a temperature of 50°C Replace the copper and lead ions in the solution with zinc flakes, filter to obtain the metal mixture filter residue and filtrate of copper and ...

example 2

[0043] (1) Prepare quaternary ammonium salt and oxalic acid according to the molar ratio of 1:1 to make oxalic acid-based deep eutectic solvent.

[0044] (2) Add zinc oxide dust (61% zinc content) into the deep eutectic solvent prepared in step (1) according to the solid-to-liquid ratio of 1:20, stir and leach for 8 hours at 70°C, and add to the leachate Distilled water was added to the mixture, and the volume ratio of leachate and distilled water was 1:20. After stirring evenly, it was left to stand for 20 minutes, and a filter residue rich in zinc oxalate was obtained by solid-liquid separation.

[0045] (3) Add the zinc oxalate-rich filter residue obtained in step (2) into the newly prepared oxalic acid-based deep eutectic solvent at a ratio of 1:10, stir and dissolve at 70°C for 2 hours, and then add zinc oxalate at 50°C Replace the copper and lead ions in the solution, filter to obtain the copper and lead metal mixture filter residue and filtrate, add distilled water 5 ti...

example 3

[0047] (1) Prepare quaternary ammonium salt and oxalic acid according to the molar ratio of 1:1 to make oxalic acid-based deep eutectic solvent.

[0048] (2) Add zinc oxide dust (48% zinc content) into the deep eutectic solvent prepared in step (1) according to the solid-to-liquid ratio of 1:30, stir and leach for 6 hours at 80°C, and add to the leachate Distilled water was added to the mixture, and the volume ratio of leachate and distilled water was 1:20. After stirring evenly, let it stand for 10 minutes. After solid-liquid separation, a filter residue rich in zinc oxalate was obtained.

[0049] (3) Add the zinc oxalate-rich filter residue obtained in step (2) into the newly prepared oxalic acid-based deep eutectic solvent at a ratio of 1:10, stir and dissolve at 80°C for 1 hour, and then add zinc oxalate at 70°C Replace the copper and lead ions in the solution, filter to obtain the copper and lead metal mixture filter residue and filtrate, add distilled water 10 times its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com