Device and method used for water electrolysis hydrogen production and CO2 methanation production of synthetic natural gas

A technology for synthesizing natural gas and electrolyzing water, applied in the direction of electrolysis process, electrolysis components, gas fuel, etc., can solve the problems of low energy conversion efficiency, complex process flow, limited application, etc., and achieve the goal of reducing preparation cost, pollution and energy The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

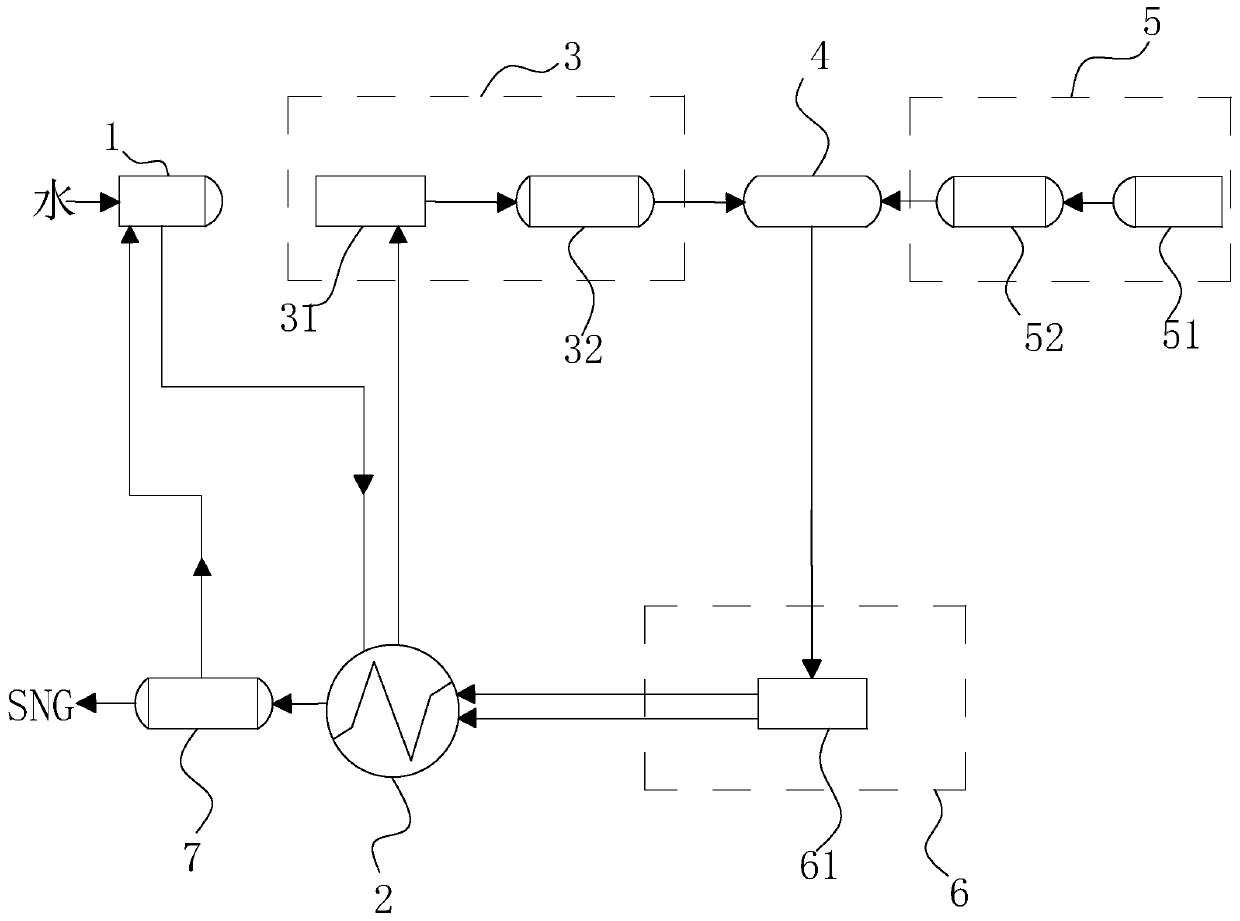

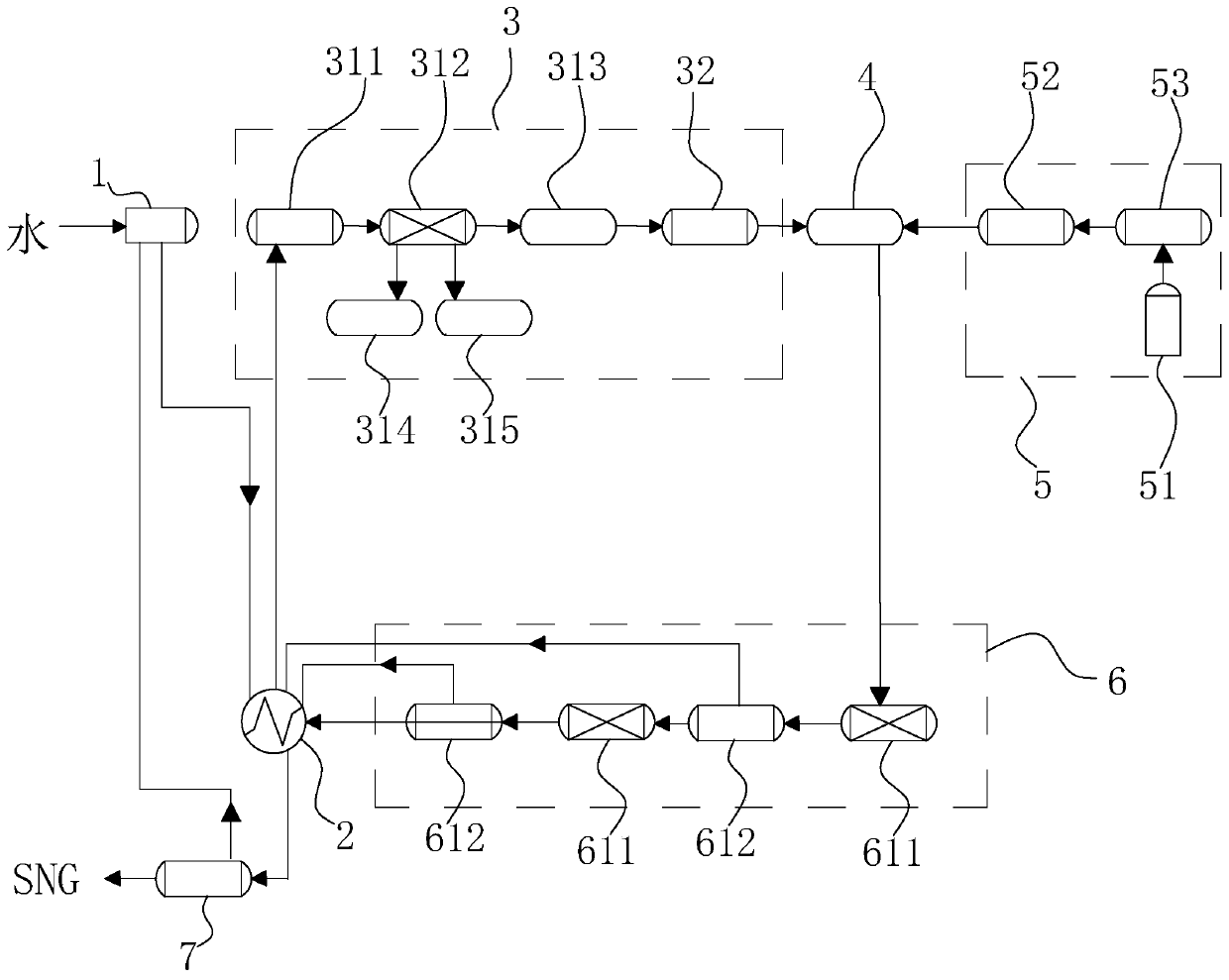

[0029] Such as Figure 1-3 As shown, a device for producing hydrogen by electrolysis of water and methanation of CO2 to produce synthetic natural gas includes a hydrogen production unit 3 by electrolysis of water, a carbon dioxide generation unit 5 and a methanation unit 6 .

[0030] The water outlet of the water tank 1 is connected to the electrolytic water hydrogen production unit 3 through the pipeline through the heat exchanger 2, the electrolytic water hydrogen production unit 3 and the carbon dioxide generation unit 5 are respectively connected to the gas mixer 4, and the mixed gas outlet of the gas mixer 4 is through a pipeline It is connected with the methanation unit 6, and the methanation unit 6 is connected with the heat exchanger 2 and the gas-liquid separation reactor 7 in sequence, and the liquid outlet of the gas-liquid separation reactor 7 is connected with the water tank through a pipeline.

[0031] The electrolytic water hydrogen production unit 3 includes an...

Embodiment 2

[0042] The device of this embodiment is as figure 1 shown.

[0043] The preparation steps are as follows:

[0044] A. After the water is pretreated by the water tank 1, it is treated by the heat exchanger 2 to become superheated steam and enters the electrolytic water hydrogen production device 31 in the electrolytic water hydrogen production unit 3, and the hydrogen produced enters the hydrogen purification device 32 and is purified. Enter gas mixer 4.

[0045] CO in the carbon source device 51 in B, carbon dioxide generating unit 5 2 After entering the carbon dioxide purification unit 52 for purification, enter the gas mixer 4, CO 2 The gas volume ratio with hydrogen is 1:4-6, fully mixed with hydrogen and heated to 250-450°C, the mixed gas enters the catalytic reaction kit 61 in the methanation unit 6, and obtains 275-375°C high-temperature methane gas and high-temperature water vapor.

[0046] C. High-temperature methane gas and high-temperature water vapor enter the ...

Embodiment 3

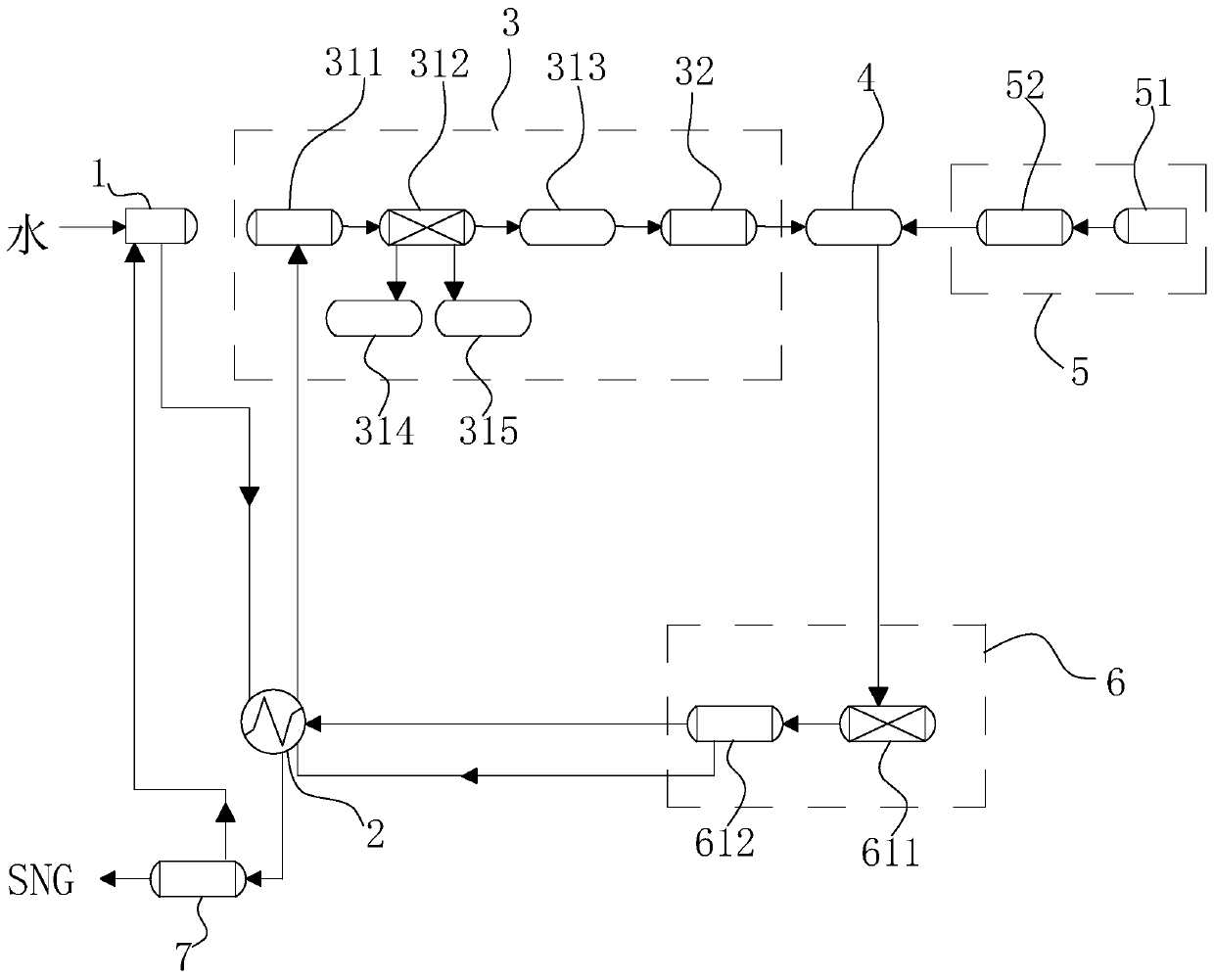

[0051] The device of this embodiment is as figure 2 shown.

[0052] The preparation steps are as follows:

[0053] A. After the water is pretreated by the water tank 1, it is treated by the heat exchanger 2 to become superheated steam and enters the electrolytic water hydrogen production device 31 in the electrolytic water hydrogen production unit 3, and is further processed by the steam treatment device 311 and mixed with a small amount of hydrogen. The gas after the steam treatment device enters the electrolysis water hydrogen production equipment 312 for the electrolysis water hydrogen production reaction, the hydrogen produced by the reaction enters the hydrogen gas collection device 313, the oxygen produced by the reaction enters the oxygen collection device 314, and the waste gas generated by the reaction enters the waste gas collection device 315. The hydrogen in the hydrogen collecting device 313 enters the hydrogen purifying device 32 for purification and then enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com