Rapid disassembling type supporting device and using method thereof

A support device and quick-release technology, which is applied to formwork/formwork/work frame, joints of formwork/formwork/work frame, preparation of building components on site, etc., can solve the inconvenience of concrete formwork support at the opening, The construction quality cannot be guaranteed, and problems such as position deviation are prone to occur, so as to achieve the effects of safe and reliable project quality, reduced project cost, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

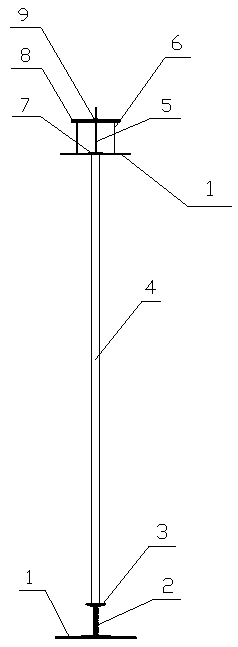

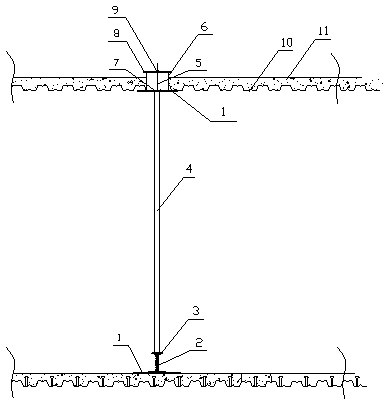

[0031] The quick-detachable supporting device of the present invention is used for pre-embedded casing pipe holes, reserved holes, and holes of profiled steel plate floor slabs, and includes a base, a vertical pole, and a hole-blocking cover.

[0032] see now figure 1 , figure 1 It is a structural schematic diagram of the supporting device of the embodiment of the present invention. As shown in the figure, the base is a top wire 2, and the top wire is vertically arranged on the template 1 on the upper surface of the profiled steel plate floor plate, and the top of the top wire is provided with a top wire adjusting nut 3.

[0033] Described upright bar is common scaffolding steel pipe 4, and the bottom end of upright bar is supported on jackscrew adjusting nut, and the top of upright bar bears against the formwork 1 below the hole that covers upper laminated steel plate floor plate.

[0034] The hole cover includes an inverted T-shaped bracket, a rubber plug 6, and a cover pl...

Embodiment 2

[0036] The method for using the quick-detachable support device of the present invention comprises the following steps:

[0037] a. Use a plasma cutting machine to cut out the holes that need to be left on the upper laminated steel plate.

[0038] b. Use ordinary scaffolding steel pipes and adjustable top wires to support the 40cm*40cm waste formwork at the bottom of the hole in the profiled steel plate to prevent the steel plate from collapsing due to hole cutting.

[0039] c. Weld an inverted T-shaped piece by using waste pull-up screws and grounded galvanized flat steel waste, drill 4 holes in the flat steel of the inverted T-shaped piece, and fix it on the formwork with nails or screws.

[0040] d. Use a rubber tube with a thickness of 4mm to stuff it into the cut hole, use the waste template to punch a round hole in the center to make a pressure plate device for pressing and fixing the rubber tube, and fix the pull screw and the compression screw to make the hole pre-buri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com