Method for one-step preparation of ceramic microfiltration membrane on basis of cross-linking reaction and product prepared by using same

A ceramic microfiltration and cross-linking reaction technology, applied in the field of ceramic membranes, can solve the problems of difficult control of membrane defects, increased separation resistance, low permeability of pure water, etc., and achieves controllable membrane thickness, good bonding, and simplification. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a method for preparing a ceramic microfiltration membrane in one step based on a cross-linking reaction, the steps are as follows:

[0029] (1) Preparation of separation membrane coating solution

[0030] The raw material composition of the separation membrane coating solution is: α-Al with a particle size D50 of 0.2 μm 2 o 3 25wt% powder, 30wt% PVA solution with a concentration of 12%, 45w% water, and dispersant DOLAPIX CE64 in an amount of 0.2wt% of the total amount of the above composition; first add the above dispersant to water, and then add α-Al 2 o 3 After the powder forms a mixed liquid, ultrasonically disperse for 1 h; then add the above PVA solution at room temperature to form a suspension; disperse the suspension by ball milling for 5 h to obtain a separation membrane coating liquid;

[0031] (2) Support body pretreatment

[0032] Immerse the flat ceramic membrane support body in a borax solution with a concentration of 0.5% for 2 seco...

Embodiment 2

[0037] In this embodiment, a method for preparing a ceramic microfiltration membrane in one step based on a cross-linking reaction, the steps are as follows:

[0038] (1) Preparation of separation membrane coating solution

[0039] The raw material composition of the separation membrane coating solution is: α-Al with a particle size D50 of 0.3 μm 2 o 3 20wt% powder, 30wt% PVA solution with a concentration of 12%, 50w% water, and the dispersant DOLAPIX CE64 in an amount of 0.3wt% of the total amount of the above composition; first add the above dispersant to the water, and then add α-Al 2 o 3 After the powder forms a mixed liquid, ultrasonically disperse for 2 hours; then add the above PVA solution at room temperature to form a suspension; disperse the suspension by ball milling for 3 hours to obtain a separation membrane coating liquid;

[0040] (2) Support body pretreatment

[0041] Immerse the flat ceramic membrane support body in a borax solution with a concentration of...

Embodiment 3

[0045] In this embodiment, a method for preparing a ceramic microfiltration membrane in one step based on a cross-linking reaction, the steps are as follows:

[0046] (1) Preparation of separation membrane coating solution

[0047] The raw material composition of the separation membrane coating solution is: ZrO with a particle size D50 of 0.4 μm 230wt% powder, 25wt% PVA solution with a concentration of 12%, 45w% water, and dispersant DOLAPIX CE 64 in an amount of 0.1wt% of the total amount of the above composition; first add the above dispersant to water, then add ZrO 2 After the powder forms a mixed liquid, ultrasonically disperse for 1.5 hours; then add the above PVA solution at room temperature to form a suspension; disperse the suspension by ball milling for 4 hours to obtain a separation membrane coating liquid;

[0048] (2) Support body pretreatment

[0049] Immerse the flat ceramic membrane support body in a borax solution with a concentration of 1% for 2 seconds, tak...

PUM

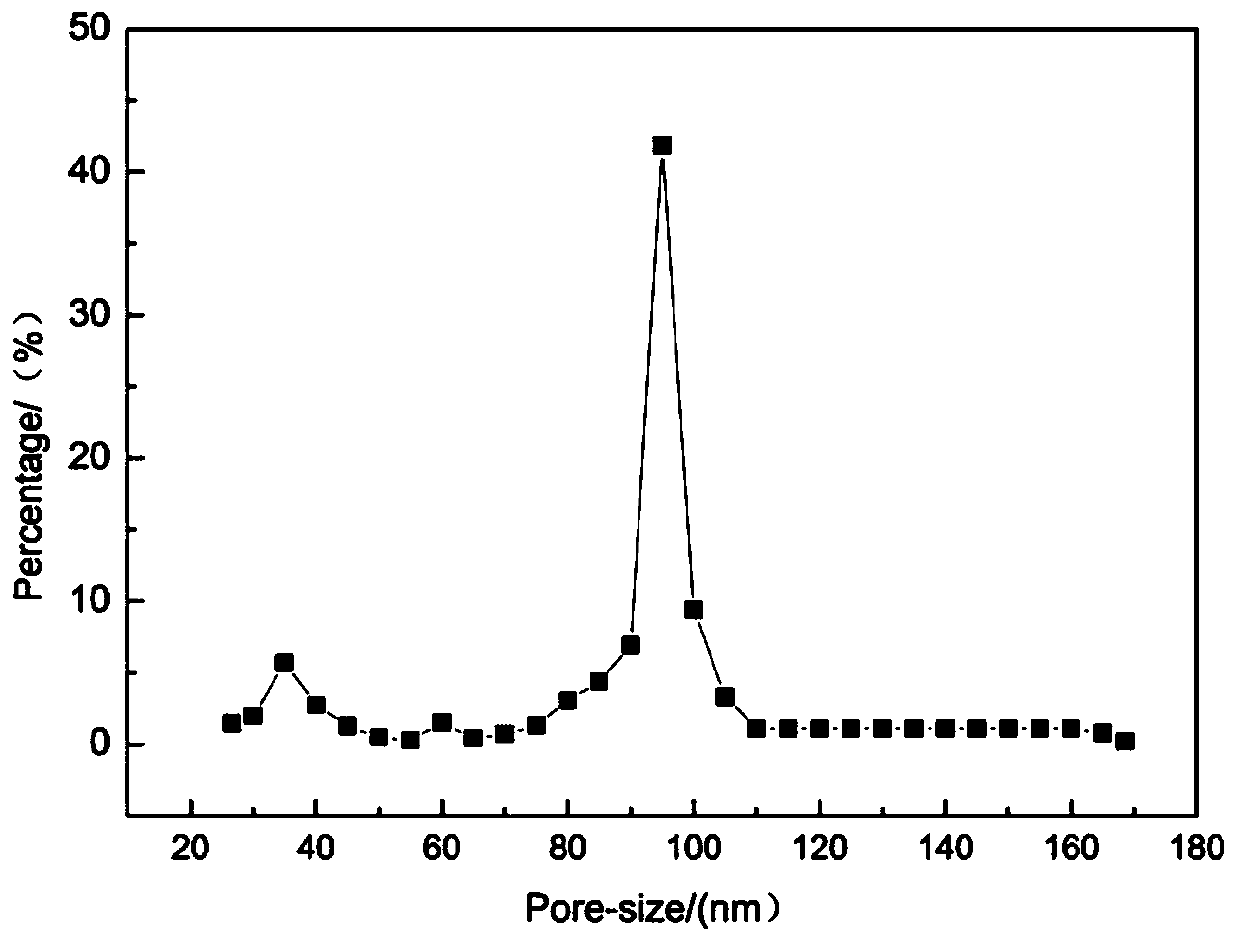

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com