Synthesis method of multi-stage pore structure zeolite nanosheet

A synthesis method and nanosheet technology, applied in the direction of crystalline aluminosilicate zeolite, mercerized crystalline aluminosilicate zeolite, chemical instruments and methods, etc., can solve the problem of expensive template agent, low integrity of nanosheets, stripping and purification process Complicated and other issues, to achieve the effects of reduced preparation costs, good mechanical stability, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) 2.57g tetrapropylammonium hydroxide solution (25wt.%) was mixed with 12.475g deionized water, and stirred evenly to obtain solution A (the concentration of tetrapropylammonium hydroxide was 0.21M);

[0055] (2) Add 0.2 g of a pure silicon-type MFI zeolite molecular sieve precursor with a c-axis size of 0.4 μm to the above-mentioned solution A, and after uniform dispersion, a solution B is obtained;

[0056] (3) Put solution B into a crystallization kettle, and conduct a hydrothermal reaction at 170°C for 18 hours;

[0057] (4) After the step (3) is completed, the obtained solid product is centrifuged, washed with water, dried at 100°C for 12h, and calcined at 550°C for 6h to obtain MFI zeolite nanosheets with a c-axis size of 0.3μm. .

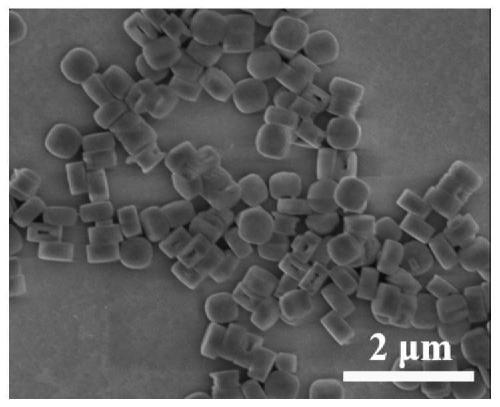

[0058] The scanning electron microscope characterization of pure silicon type MFI zeolite molecular sieve is as follows: figure 2 As shown, the morphology of the molecular sieve is coffin-shaped, and the particle size (0.4 μm) is ...

Embodiment 2

[0060] (1) Mix 4.6g of tetrapropylammonium hydroxide solution (25wt.%) with 22.329g of deionized water, and stir evenly to obtain solution A (the concentration of tetrapropylammonium hydroxide is 0.21M);

[0061] (2) Add 0.4 g of the pure silicon-type MFI zeolite molecular sieve precursor with a c-axis size of 0.4 μm to the above solution A, and obtain solution B after uniform dispersion;

[0062] (3) Put solution B into a crystallization kettle, and conduct a hydrothermal reaction at 170°C for 18 hours;

[0063] (4) After the step (3) is completed, the obtained solid product is centrifuged, washed with water, dried at 100°C for 12h, and calcined at 550°C for 6h to obtain MFI zeolite nanosheets with a c-axis size of 0.3μm. .

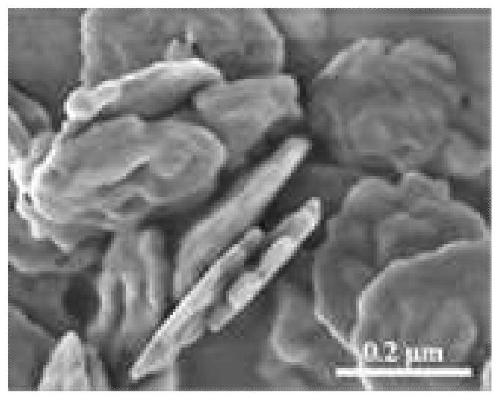

[0064] The scanning electron microscope characterization of the obtained nanosheets is as follows: Figure 4 As shown, the nanosheets are also monodisperse sheet-like structures.

Embodiment 3

[0066] (1) 2.91g tetrapropylammonium hydroxide solution (25wt.%) was mixed with 13.585g deionized water, and stirred evenly to obtain solution A (the concentration of tetrapropylammonium hydroxide was 0.217M);

[0067] (2) Add 0.2 g of the pure silicon-type MFI zeolite molecular sieve precursor with a c-axis size of 1.2 μm to the above solution A, and obtain solution B after uniform dispersion;

[0068] (3) Put solution B into a crystallization kettle, and conduct a hydrothermal reaction at 170°C for 18 hours;

[0069] (4) After the step (3) is completed, the obtained solid product is centrifuged, washed with water, dried at 100°C for 12 hours, and calcined at 550°C for 6 hours to obtain MFI zeolite nanosheets with a c-axis size of 1.0 μm. .

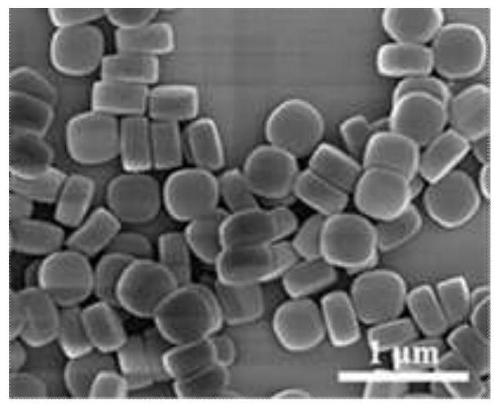

[0070] The scanning electron microscope characterization of pure silicon type MFI zeolite molecular sieve is as follows: Figure 5 As shown, the shape of the molecular sieve is coffin-shaped, and the particle size (0.9×0.45×1.2μm 3 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com