Integrated biochemical treatment method for high-salt wastewater

A technology for biochemical treatment and high-salt wastewater, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problems of poor biochemical treatment of saline wastewater, frequent equipment maintenance, high operating costs, etc. problems, to achieve obvious energy-saving effects, speed up domestication, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

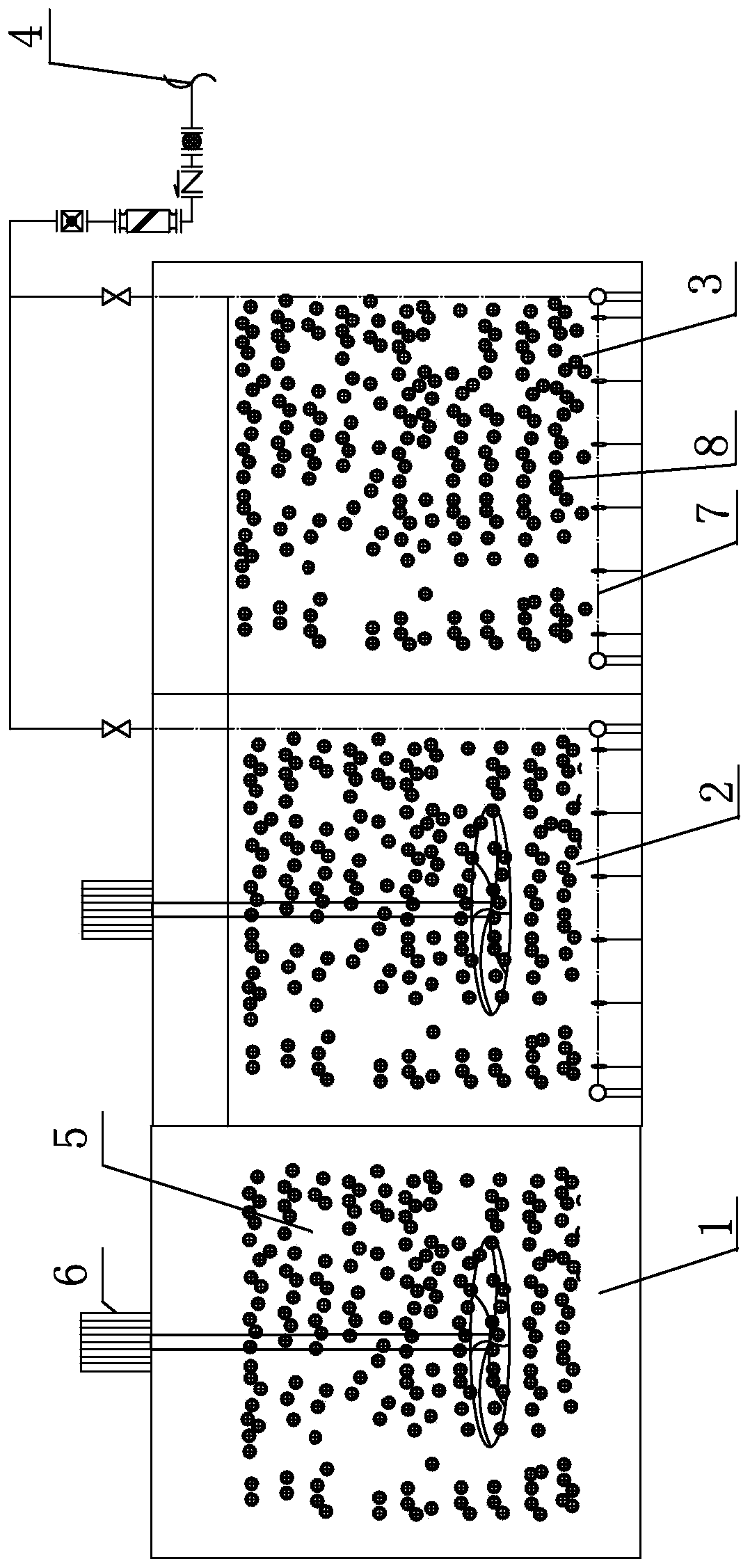

Embodiment 1

[0033] For a spice synthesis chemical project, the treated water volume is 1200t / d, the influent CODcr, ammonia nitrogen, and salinity are respectively 10,000mg / L, 120mg / L, and 2% (mixed salt mainly composed of sodium sulfate and sodium acetate), and the effluent CODcr and ammonia nitrogen are required to reach 400mg / L and 30mg / L respectively, and high-salt combined biochemical process (anaerobic + facultative + aerobic) is used for treatment, in which the salt-tolerant bacteria are added externally, and the total amount of dosage is about 200mg / L, and added 2g / L biochemical sludge, adopting batch dosing method, adopting 3000mg / L step-up domestication method; the system uses microporous aeration plate for aeration, uses sedimentation tank to intercept sludge, and does not use carrier Filler, by adjusting pH (6-8.5), DO (DO in the anaerobic section is about 0.05mg / L, DO in the anoxic section is 0.15mg / L, and DO in the aerobic section is about 3mg / L), ORP (anoxic section range ...

Embodiment 2

[0035] For a new material production project, the water treatment volume is 1000t / d, the influent CODcr, ammonia nitrogen, and salinity are 4000mg / L, 50mg / L and 3% (mixed salt mainly composed of sodium sulfate and sodium chloride), and the effluent CODcr , ammonia nitrogen are required to reach 300mg / L and 25mg / L respectively, and are treated with a high-salt combined biochemical process (facultative oxygen + aerobic) treatment, in which the salt-tolerant bacteria are added externally, and the total dosage is about 100mg / L. Added 1.5g / L biochemical sludge, adopted batch dosing method, and adopted 4000mg / L step-up domestication method; (6.5-8.5), DO (the DO in the anoxic section is 0.25mg / L, and the DO in the aerobic section is about 2mg / L), ORP (-200mV in the anoxic section), temperature (18-35℃), and combined The dosing of key activation elements (the dosing concentrations of iron, cobalt, and nickel are 2mg / L, 0.4mg / L, and 0.4mg / L respectively, and the dosing ratio of C, N, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com