High-strength tempered glass cover plate chemical polishing reagent and polishing method

A chemical polishing and tempering glass technology, applied in the field of chemical polishing, can solve the problems of fast reaction speed, large environmental pollution, difficult control, etc., and achieve the effects of improving production efficiency, improving hydrophilicity, increasing strength and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

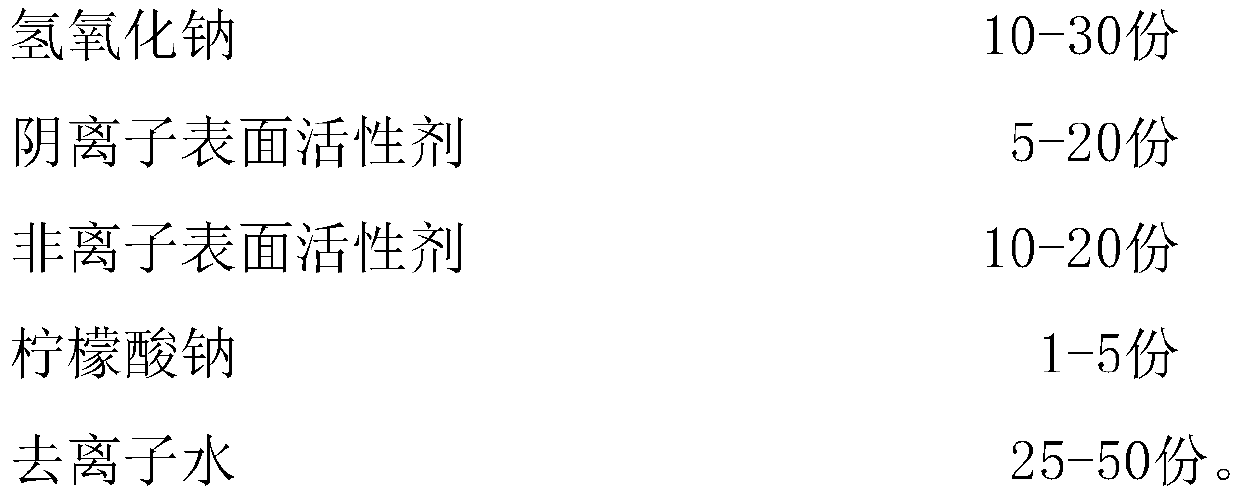

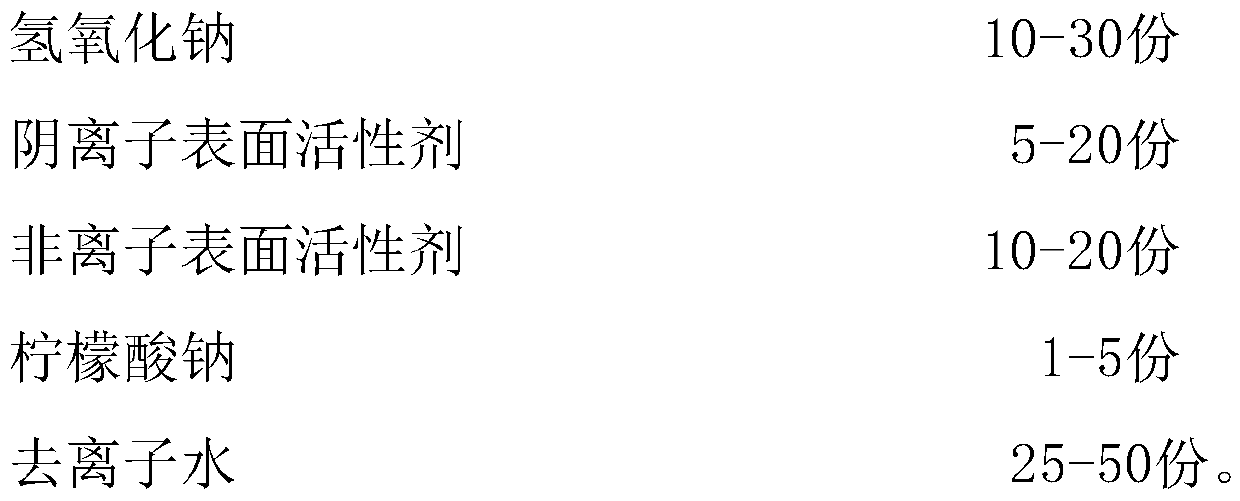

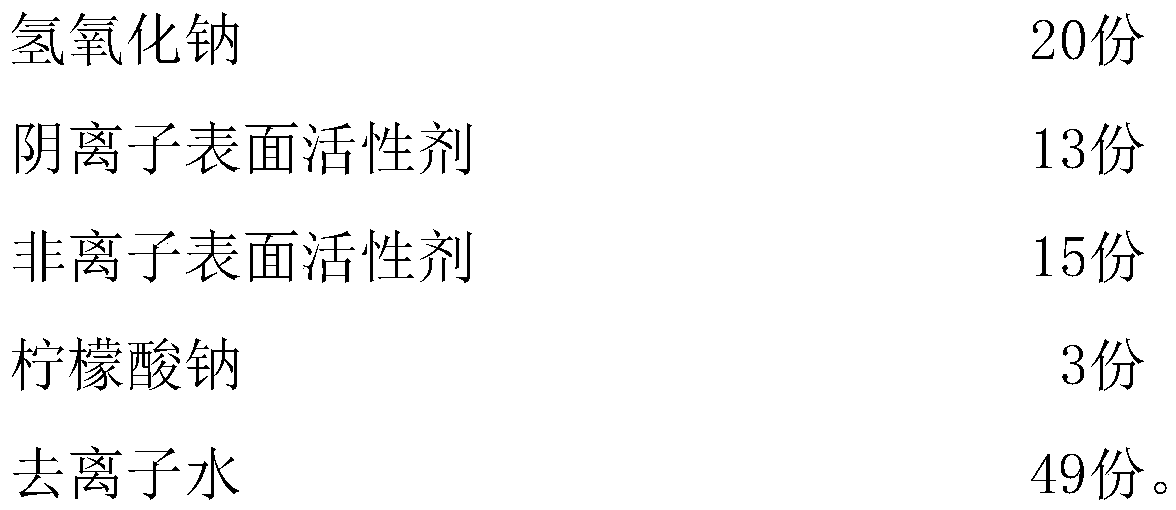

[0037] A high-strength tempered glass cover plate chemical polishing agent, which includes the following raw materials in parts by weight:

[0038]

[0039] The anionic surfactant is sodium dodecylsulfonate; the nonionic surfactant is AEO-9.

[0040] The preparation method of the above-mentioned chemical polishing reagent is as follows: according to the parts by weight of each raw material, first mix each raw material, then raise the temperature of the mixed solution to 40°C, and finally stir at a speed of 200r / min for 17.5min to obtain the chemical polishing reagent. Polishing reagent.

[0041] The method for chemically polishing the high-strength tempered glass cover includes the following preparation steps:

[0042] A. Cutting, cut a large piece of glass into small pieces of glass; then carry out CNC edge grinding and drilling on the glass, laminate and polish the CNC processed glass, so that the rough surface produced by CNC on the edge of the glass is polished, The s...

Embodiment 2

[0048] A high-strength tempered glass cover plate chemical polishing reagent, the difference between embodiment 2 and embodiment 1 is that the anionic surfactant is sodium dodecylsulfonate, sodium dodecylbenzenesulfonate by weight ratio of 1:1 composition mixture.

[0049] The nonionic surfactant is a mixture of AEO-9 and glycerol polyoxyethylene polyoxypropylene ether in a weight ratio of 1:1.

[0050] The preparation method of the chemical polishing reagent for the high-strength tempered glass cover plate and the chemical polishing method for the high-strength tempered glass cover plate in Example 2 are the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0052] A high-strength tempered glass cover plate chemical polishing reagent, the difference between embodiment 3 and embodiment 1 is that the anionic surfactant is sodium dodecylsulfonate, sodium dodecylbenzenesulfonate, isooctyl alcohol A mixture of ether phosphates in a weight ratio of 1:1:1.

[0053] The nonionic surfactant is a mixture of AEO-9, glycerol polyoxyethylene polyoxypropylene ether, and alkylphenol polyoxyethylene ether in a weight ratio of 1:1:1.

[0054] The preparation method of the chemical polishing agent for the high-strength tempered glass cover plate and the chemical polishing method for the high-strength tempered glass cover plate in Example 3 are the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com