Method for preparing prefabricated kerbs through asphalt pavement surface layer milling material regeneration

A technology for asphalt pavement and milling material, which is applied in the direction of side ditch/curb stone, road, road, etc., can solve the problems of reducing the cost of curb stone engineering, poor corrosion resistance and durability, difficult maintenance and replacement, etc., to save The effect of sand and gravel materials and asphalt resources, excellent salt corrosion resistance, easy installation, construction and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing prefabricated curbs by regenerating asphalt pavement surface milling material, which is prepared from the following components, by weight: 30 parts of RAP material (0-5mm), 30 parts of RAP material (5-10mm) , 20 parts of RAP material (10-20mm), 0.5 parts of regeneration agent, 8 parts of fiber reinforcement, 6 parts of stabilizer, 2 parts of new asphalt, 8 parts of rubber powder, 20 parts of corrosion resistance agent, 2.5 parts of waterproof and oil resistance agent, rosin 5.2 parts and 7.5 parts of inorganic nano-ceramic thermal insulation coating. The regenerant is the road-specific regenerant RA-5 produced by Hubei Dingshun Petrochemical Co., Ltd. The fiber reinforcing agent is Shenzhen Haichuan De Lanite Co., Ltd. AS polyacrylonitrile fiber reinforcement. The stabilizer is lignin fiber for Kentley road. The new asphalt is road petroleum asphalt, the label is No. 90, the place of production is Liaohe, Panjin, the softening point is ≥ 45°C...

Embodiment 2

[0049] The difference from Example 1 is that the components are by weight: 35 parts of RAP material (0-5mm), 38 parts of RAP material (5-10mm), 25 parts of RAP material (10-20mm), 0.3 part of regeneration agent , 4.2 parts of fiber reinforcing agent, 4.6 parts of stabilizer, 2.3 parts of new asphalt, 12 parts of rubber powder, 22 parts of corrosion resistant agent, 2.8 parts of waterproof and oil resistant agent, 6.5 parts of rosin, 8 parts of inorganic nano-ceramic thermal insulation coating. The distribution ratio is: in step two, regeneration agent (0.1 parts), fiber reinforcement (2 parts), stabilizer (2.2 parts); in step three, regeneration agent (0.2 parts), fiber reinforcement (2.2 parts), stabilizer agent (2.4 parts).

Embodiment 3

[0051] The difference from Example 1 is that the components are by weight: RAP material (0-5mm): 42 parts, RAP material (5-10mm) 40 parts, RAP material (10-20mm) 28 parts, regeneration agent 0.33 6 parts, 6 parts of fiber reinforcement, 5 parts of stabilizer, 3.5 parts of new asphalt, 15 parts of rubber powder, 25 parts of anti-corrosion agent, 3 parts of waterproof and oil-resistant agent, 7.2 parts of rosin, 10 parts of inorganic nano-ceramic thermal insulation coating. The distribution ratio is: in step two, regeneration agent (0.1 parts), fiber reinforcement (2.2 parts), stabilizer (2.3 parts); in step three, regeneration agent (0.23 parts), fiber reinforcement (3.8 parts), stabilizer agent (2.7 parts).

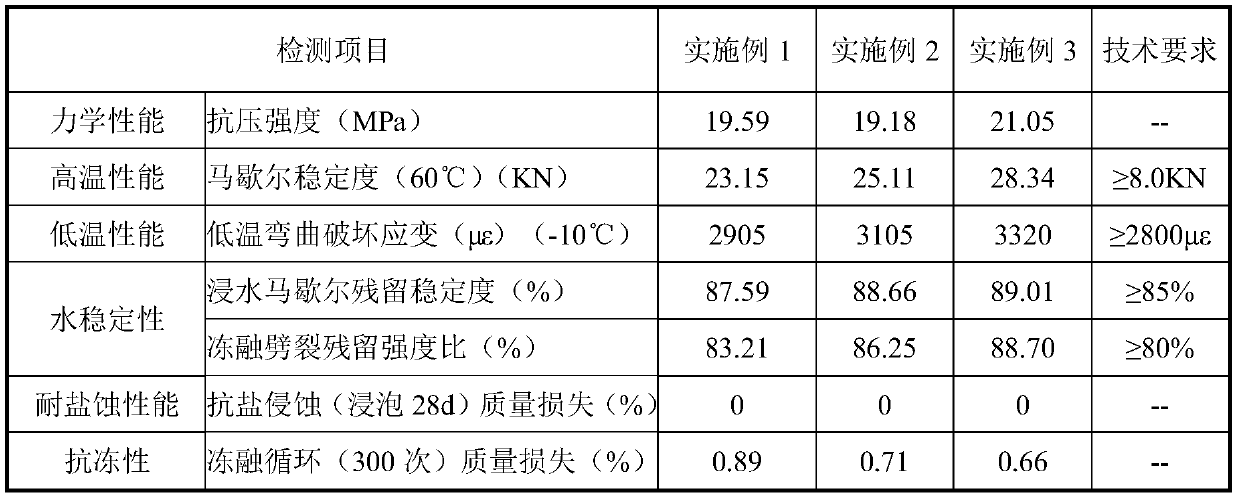

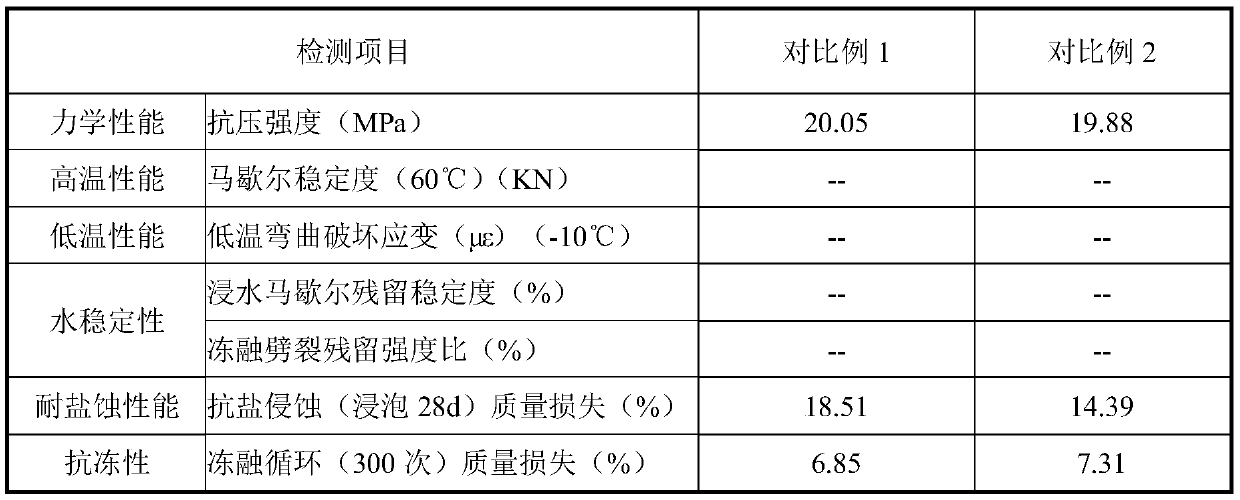

[0052] Examples 1-3 Asphalt pavement surface layer milling material recycled prefabricated curb road performance testing results are shown in Table 1:

[0053] Table 1

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com