A kind of preparation method of azo oxide and azo stilbene dye

A technology of azo oxide and stilbene, which is applied in the field of dyes, can solve the problems of non-separation, inconvenient dyes, and unusability, and achieve good cellulose affinity, simple process steps, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

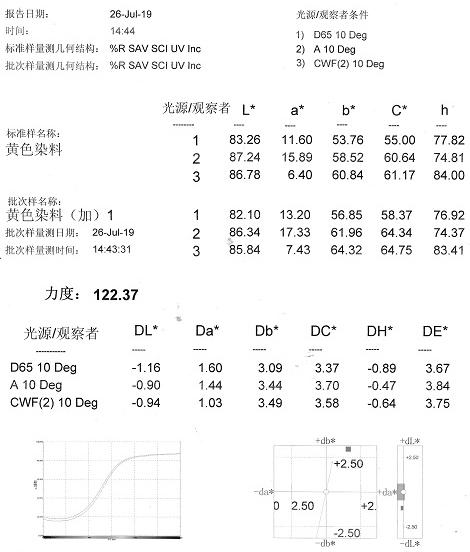

[0036] The preparation method of dye Direct Yellow 11 is as follows:

[0037] Slowly add 11.9 parts of 4-nitrotoluene-2-sulfonic acid to 44 parts of 25% tetramethylammonium hydroxide aqueous solution (40°C), and stir to form a blue-purple solution. At 70°C, the reaction was stirred for 5h. After the reaction, a reddish-brown transparent solution was formed, and 4.7 parts of 30% hydrochloric acid was added to the solution to adjust the pH to 8 to obtain a yellow solution with a maximum absorption wavelength of 414 nm.

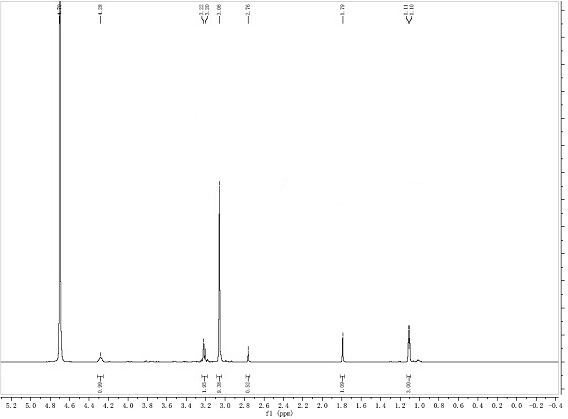

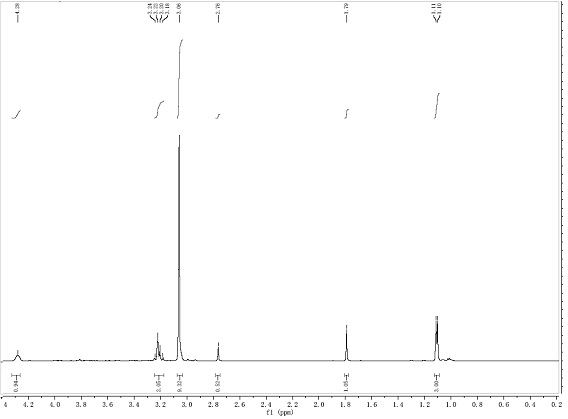

[0038] Dye structural formula I, as shown in the figure below:

[0039] (I)

[0040] Among them, X represents the group N ⊕ (CH 3 ) 4 .

Embodiment 2

[0042] The preparation method of dye Direct Yellow 11 is as follows:

[0043] Slowly add 4-nitrotoluene-2-sulfonic acid to 15% tetramethylammonium hydroxide aqueous solution, the molar ratio of 4-nitrotoluene-2-sulfonic acid to tetramethylammonium hydroxide is 1:2, Stir to form a blue-violet solution. At 65°C, the reaction was stirred for 8h. After the reaction, a reddish-brown transparent solution was formed, and hydrochloric acid was added to the solution to adjust the pH to 7 to obtain a yellow solution with a maximum absorption wavelength of 410 nm.

[0044] Structure is with embodiment 1.

Embodiment 3

[0046] The preparation method of dye Direct Yellow 11 is as follows:

[0047]Slowly add 4-nitrotoluene-2-sulfonic acid to 30% tetramethylammonium hydroxide aqueous solution (40°C), the molar ratio of 4-nitrotoluene-2-sulfonic acid to tetramethylammonium hydroxide 1:5, stirring to form a blue-purple solution. The reaction was stirred at 85 °C for 4 h. After the reaction, a reddish-brown transparent solution was formed, and hydrochloric acid was added to the solution to adjust the pH to 9 to obtain a yellow solution with a maximum absorption wavelength of 416 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com