Waterproof glue and water seepage timely maintenance and construction method for hotel toilet

A technology of toilet and waterproof glue, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of water seepage and water leakage in toilets, and achieve the effect of excellent waterproof performance, broad market, enhanced bonding performance and waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

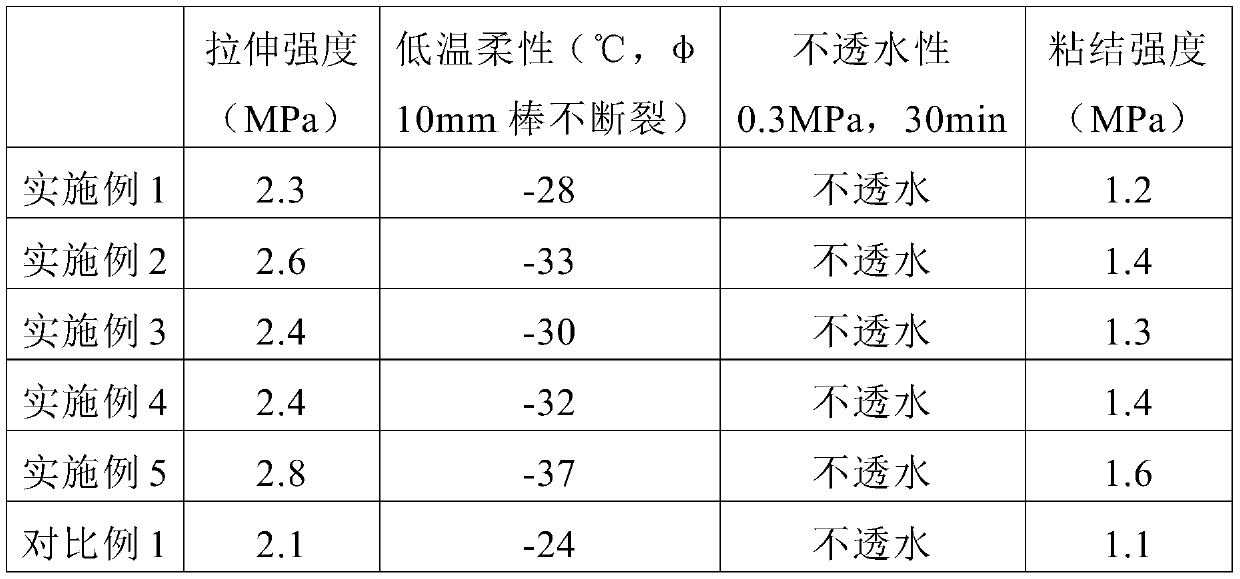

Examples

Embodiment 1

[0028] Waterproof glue for hotel toilets is prepared from the following raw materials in parts by weight: 100 parts of polyurethane modified acrylic emulsion, 5 parts of alcohol ester twelve, 5 parts of nano-titanium dioxide, 1 part of ethylene glycol, 0.2 parts of defoaming agent, 0.9 parts of leveling agent, 2 parts of thickener.

[0029] The defoamer is tributyl phosphate.

[0030] The preparation method of the polyurethane modified acrylic emulsion is as follows: (1) 100 parts by weight of deionized water, 5.5 parts by weight of sodium lauryl sulfate, 2.5 parts by weight of nonylphenol polyoxyethylene ether, and 30 parts by weight of styrene, 150 parts by weight of methyl methacrylate, 18 parts by weight of butyl acrylate, and 2 parts by weight of acrylic acid were stirred at a speed of 300 r / min for 20 minutes to obtain a pre-emulsion; 300 parts by weight of deionized water were added to the reactor, heated to 80°C, and Pre-emulsion with 10% of the total weight of the pr...

Embodiment 2

[0038] Waterproof glue for hotel toilets, prepared from the following raw materials in parts by weight: 100 parts of polyurethane modified acrylic emulsion, 5 parts of alcohol ester twelve, 5 parts of functionalized nano-titanium dioxide, 1 part of ethylene glycol, and 0.2 parts of defoaming agent , 0.9 parts of leveling agent, 2 parts of thickener.

[0039] The defoamer is tributyl phosphate.

[0040] The preparation method of the polyurethane modified acrylic emulsion is as follows: (1) 100 parts by weight of deionized water, 5.5 parts by weight of sodium lauryl sulfate, 2.5 parts by weight of nonylphenol polyoxyethylene ether, and 30 parts by weight of styrene, 150 parts by weight of methyl methacrylate, 18 parts by weight of butyl acrylate, and 2 parts by weight of acrylic acid were stirred at a speed of 300 r / min for 20 minutes to obtain a pre-emulsion; 300 parts by weight of deionized water were added to the reactor, heated to 80°C, and Pre-emulsion with 10% of the tota...

Embodiment 3

[0060] Waterproof glue for hotel toilets, prepared from the following raw materials in parts by weight: 100 parts of polyurethane modified acrylic emulsion, 5 parts of alcohol ester twelve, 5 parts of functionalized nano-titanium dioxide, 1 part of ethylene glycol, and 0.2 parts of defoaming agent , 0.9 parts of leveling agent, 2 parts of thickener.

[0061] The defoamer is tributyl phosphate.

[0062] The preparation method of the polyurethane modified acrylic emulsion is as follows: (1) 100 parts by weight of deionized water, 5.5 parts by weight of sodium lauryl sulfate, 2.5 parts by weight of nonylphenol polyoxyethylene ether, and 30 parts by weight of styrene, 150 parts by weight of methyl methacrylate, 18 parts by weight of butyl acrylate, and 2 parts by weight of acrylic acid were stirred at a speed of 300 r / min for 20 minutes to obtain a pre-emulsion; 300 parts by weight of deionized water were added to the reactor, heated to 80°C, and Pre-emulsion with 10% of the tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com