PVB adhesive film and preparation method thereof, and laminated safety glass

A film and compounding technology, applied in the direction of adhesives, film/sheet adhesives, film/sheet without carrier, etc., can solve the problem of excessive haze of PVB film, achieve good light transmission performance and insulation Thermal and sound insulation performance, good safety performance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

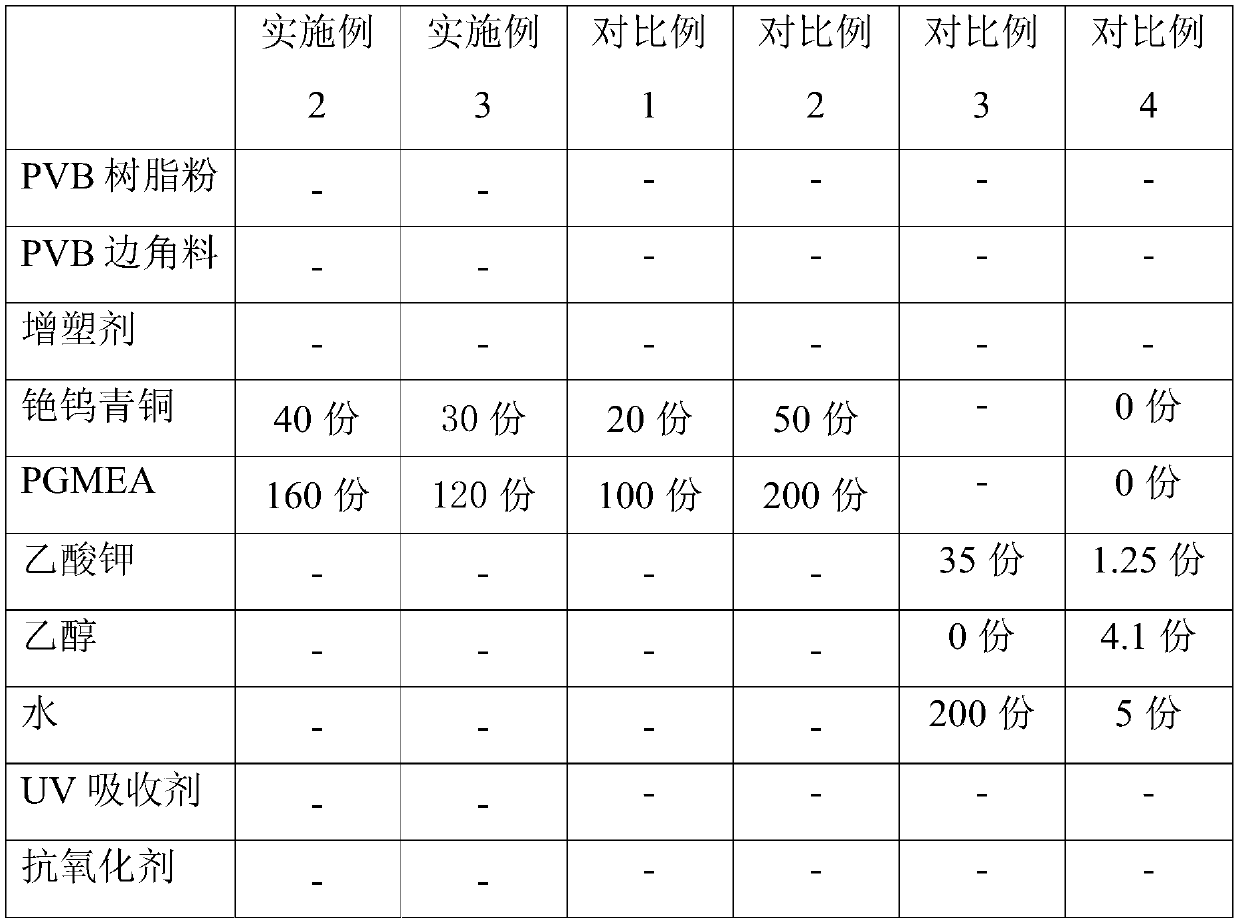

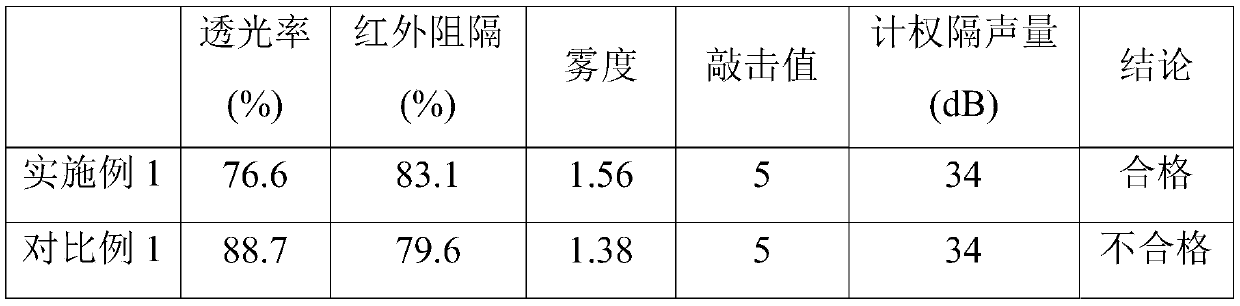

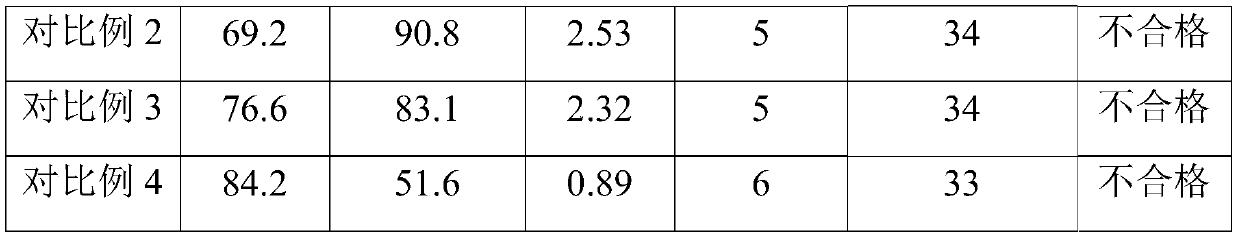

Examples

preparation example Construction

[0032] Correspondingly, a kind of preparation method of above-mentioned PVB film, comprises the following steps:

[0033] S01, performing a first mixed material treatment on the potassium acetate, the ethanol and the water to obtain a first mixed material;

[0034] S02, subjecting the cesium tungsten bronze, the propylene glycol methyl ether acetate, the plasticizer and the first mixture to a second mixture treatment to obtain a second mixture;

[0035] S03, subjecting the PVB resin and the second mixed material to a third mixed material to obtain a third mixed material;

[0036] S04, performing hot-melt extrusion on the third mixed material to form a film to obtain the PVB adhesive film.

[0037] The above-mentioned PVB adhesive film preparation method provided by the embodiment of the present invention is easy to operate, controllable in quality, and easy for mass production.

[0038] Specifically, in step S01, in the step of subjecting the potassium acetate, the ethanol, ...

Embodiment 1

[0047] The present embodiment has prepared a kind of PVB adhesive film, and concrete technological process is as follows:

[0048] S11. Weigh 35 parts of potassium acetate, 56 parts of ethanol and 140 parts of water, and stir the potassium acetate, ethanol and water at 370 rpm for 10 minutes in a mechanical mixer to obtain the first mixed material;

[0049] S12, take by weighing 34 parts of cesium tungsten bronze, 136 parts of propylene glycol methyl ether acetate and 7400 parts of plasticizer, place the first mixed material prepared by cesium tungsten bronze, propylene glycol methyl ether acetate, plasticizer and step S11 in the machine In the blender and stirred at 600rpm for 15min, the second mixture was obtained;

[0050] S13, take by weighing 20000 parts of PVB resin powder, 13500 parts of PVB leftover material, 66 parts of antioxidant and 46 parts of ultraviolet absorber, the second mixed material prepared by PVB resin powder, PVB leftover material, antioxidant, ultravio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com