Graphene oxide/tungsten disulfide composite coating and preparation method and application thereof

A technology of tungsten disulfide and composite coating, which is applied in the direction of coating, metal material coating technology, etc., to achieve the effect of reducing consumption, good bonding force and stable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Dissolve the graphene oxide powder in deionized water, and ultrasonically disperse it in an ultrasonic disperser with a power of 50W for 2h to obtain a stable dispersion with a graphene oxide concentration of 0.1g / L.

[0033] 2. Then add tungsten chloride and thioacetamide to the dispersion, wherein the concentration of tungsten chloride is 1mmol / L, the concentration of thioacetamide is 1mmol / L, and ultrasonically stirred for 30min (power is 50W).

[0034] 3. Transfer the mixed liquid after ultrasonic stirring to the hydrothermal reaction kettle, and put the brass base material in the reaction kettle at the same time. The reaction kettle was placed in a drying oven, reacted at 180°C for 8 hours, and cooled naturally to room temperature to prepare a graphene oxide / tungsten disulfide composite coating on a brass substrate.

Embodiment 2

[0036] 1. Dissolve the graphene oxide powder in deionized water, and ultrasonically disperse it in an ultrasonic disperser with a power of 80W for 2h to obtain a stable dispersion with a graphene oxide concentration of 0.2g / L.

[0037] 2. Then add tungsten chloride and thioacetamide to the dispersion, wherein the concentration of tungsten chloride is 5mmol / L, the concentration of thioacetamide is 5mmol / L, and ultrasonically stirred for 30min (power is 80W).

[0038] 3. Transfer the mixed liquid after ultrasonic stirring to the hydrothermal reaction kettle, and put the brass base material in the reaction kettle at the same time. The reaction kettle was placed in a drying oven, reacted at 220°C for 16h, and cooled naturally to room temperature to prepare a graphene oxide / tungsten disulfide composite coating on a brass substrate.

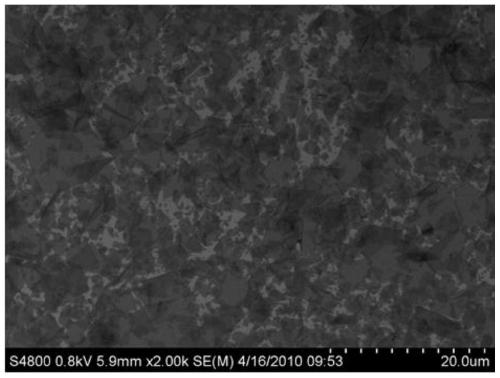

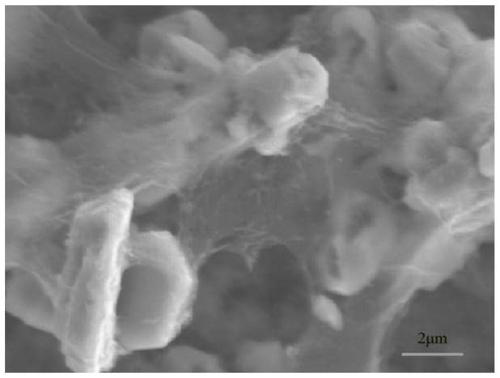

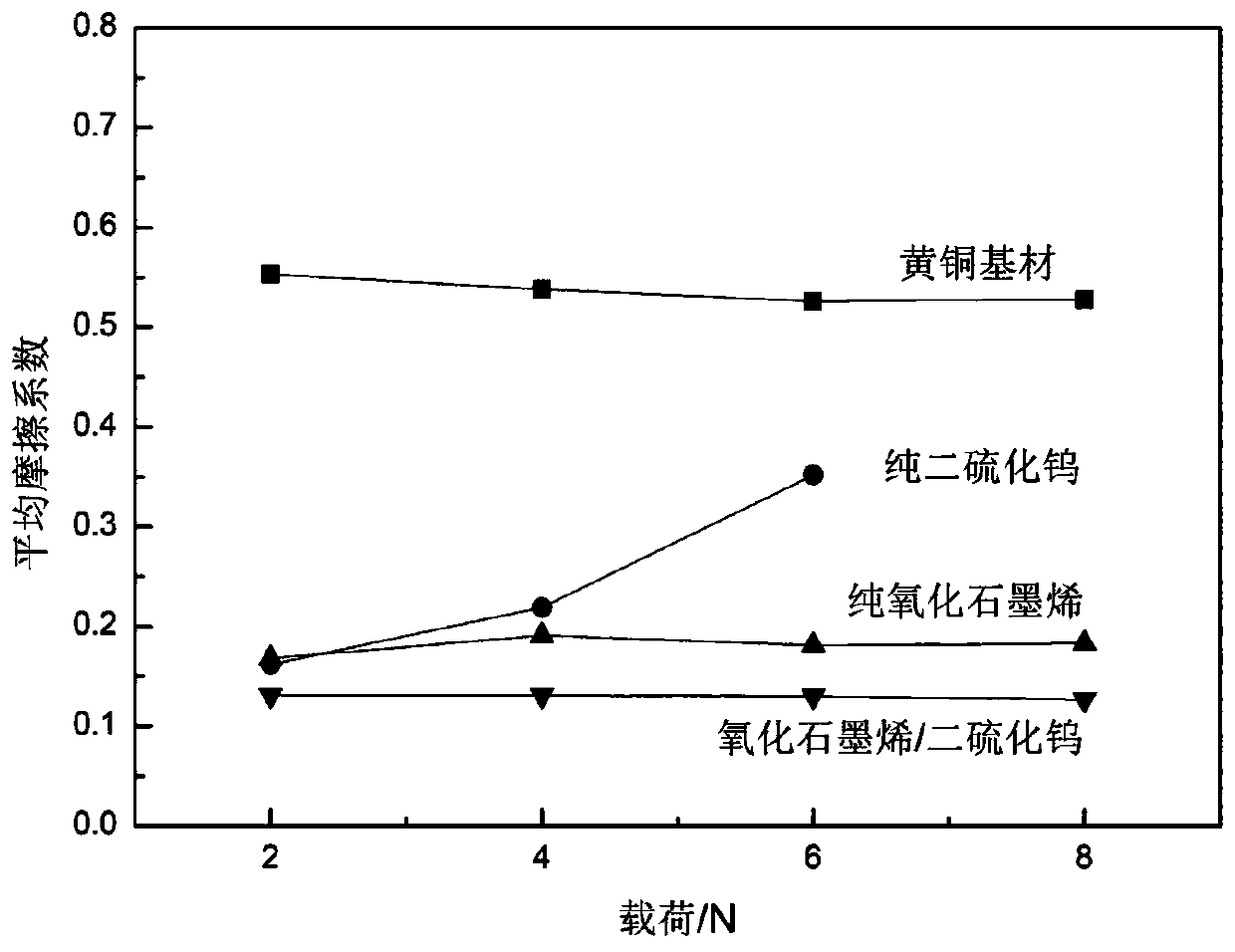

[0039] figure 1 SEM photo of the graphene oxide prepared in this embodiment. from figure 1 It can be seen from the figure that the graphene oxide s...

Embodiment 3

[0050] 1. Dissolve the graphene oxide powder in deionized water, and ultrasonically disperse it in an ultrasonic disperser with a power of 100W for 2h to obtain a stable dispersion with a graphene oxide concentration of 0.5g / L.

[0051] 2. Then add tungsten chloride and thioacetamide to the dispersion, wherein the concentration of tungsten chloride is 10mmol / L, the concentration of thioacetamide is 10mmol / L, and ultrasonically stirred for 30min (power is 80W).

[0052] 3. Transfer the mixed liquid after ultrasonic stirring to the hydrothermal reaction kettle, and put the brass base material in the reaction kettle at the same time. The reaction kettle was placed in a drying oven, reacted at 220°C for 20h, and cooled naturally to room temperature to prepare a graphene oxide / tungsten disulfide composite coating on a brass substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com