Pulse electroplating agent capable of plating high-aspect-ratio through holes and blind holes, and preparation method thereof

A high aspect ratio, pulse electroplating technology, applied in the field of pulse electroplating, can solve the problems of uncontrollable coating quality and low production efficiency at blind hole positions, and achieve the effects of improving coating positioning, improving stability, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

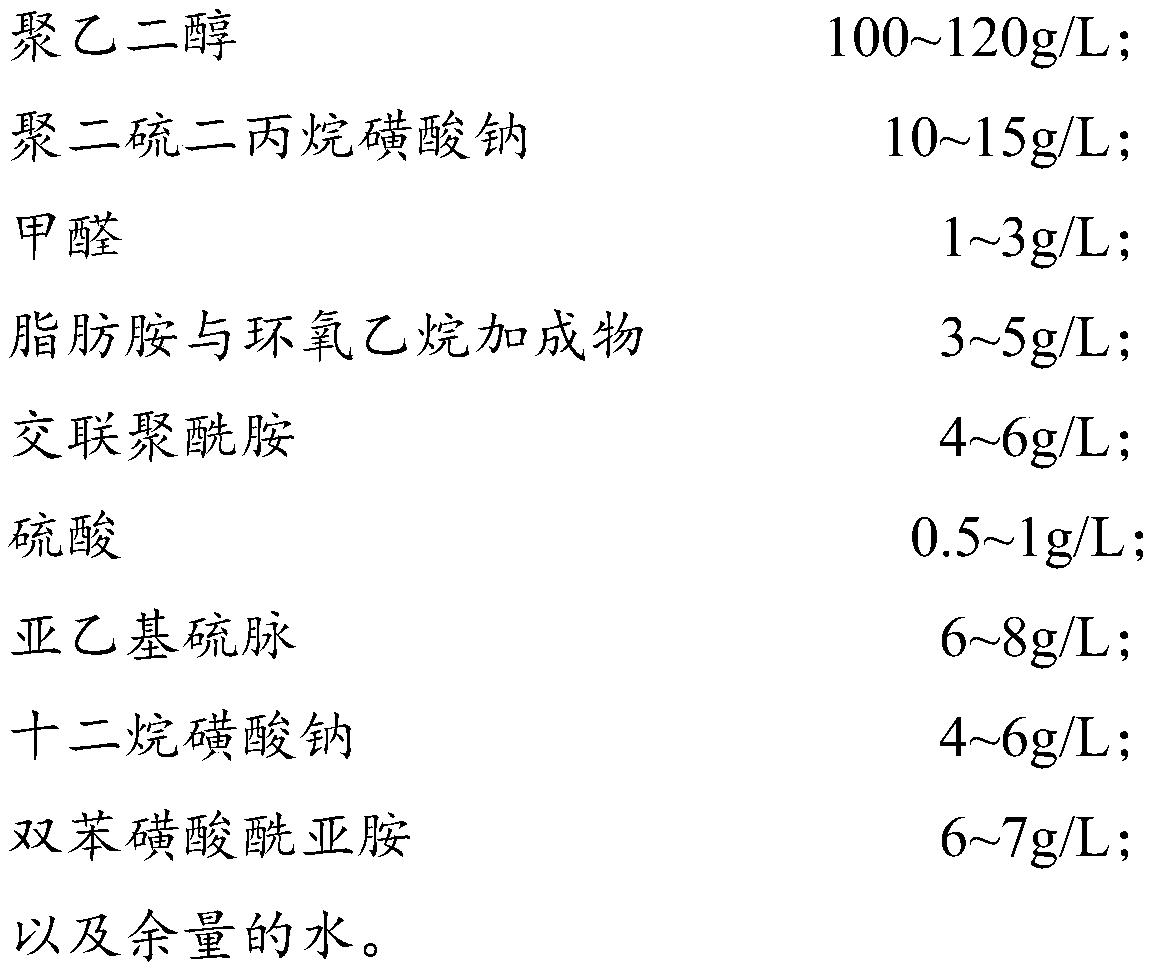

[0035] A pulse electroplating agent capable of plating high aspect ratio through holes and blind holes, comprising the following components:

[0036] 100g / L PEG20000, 10g / L SP, 1g / L formaldehyde, 3g / L DAE, 4g / L JPH, 0.5g / L sulfuric acid, 6g / L ethylenethiourea, 4g / L Sodium dodecanesulfonate, 6g / L bis-benzenesulfonic acid imide, and the rest of water.

[0037] The above-mentioned preparation method of a pulse electroplating agent capable of plating high aspect ratio through holes and blind holes comprises the following steps:

[0038] S1. Add 18-30°C deionized water and PEG20000 into the container, and stir until completely dissolved;

[0039] S2, continue to add SP to the container, stir until completely dissolved;

[0040] S3, continue to add formaldehyde, sulfuric acid in container, stir until completely dissolving;

[0041] S4, continue to add DAE in the container, stir until completely dissolved;

[0042] S5, continue to add JPH to the container and stir until completel...

Embodiment 2

[0048] A pulse electroplating agent capable of plating high aspect ratio through holes and blind holes, comprising the following components:

[0049] 120g / L PEG20000, 15g / L SP, 3g / L formaldehyde, 5g / L DAE, 6g / L JPH, 1g / L sulfuric acid, 8g / L ethylenethiourea, 6g / L Sodium dodecanesulfonate, 7g / L of bisbenzenesulfonic acid imide, and the balance of water.

[0050] The preparation method is the same as in Example 1.

Embodiment 3

[0052] A pulse electroplating agent capable of plating high aspect ratio through holes and blind holes, comprising the following components:

[0053] 110g / L PEG20000, 13g / L SP, 2g / L formaldehyde, 4g / L DAE, 5g / L JPH, 0.8g / L sulfuric acid, 7g / L ethylenethiourea, 5g / L sodium dodecanesulfonate, 6.5g / L bis-benzenesulfonic acid imide, and the rest of water.

[0054] The preparation method is the same as in Example 1.

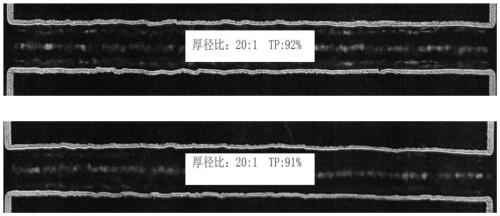

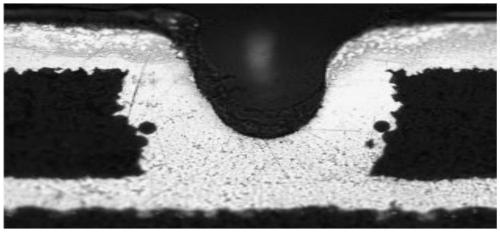

[0055] Implement application conditions

[0056] The pulse electroplating agent is mixed with copper sulfate, sulfuric acid, chloride ion, DI water, etc. according to a certain ratio to prepare an electrolytic solution for electroplating operation.

[0057] Electrolyte solution preparation

[0058] DI water: 50% volume ratio, copper sulfate: 80g / L, sulfuric acid: 220g / L, chloride ion: 60-90ppm, the pulse electroplating agent of embodiment 3: 13ml / L, surplus DI water stirs and dissolves, and solution Temperature: 24-28°C.

[0059] operating conditions

[0060] Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com