Switching emulsion based on magnetic particles and preparation method thereof

A technology of magnetic particles and emulsions, applied in the fields of magnetic materials, magnetic objects, chemical instruments and methods, etc., can solve problems such as deficiencies, and achieve the effects of short emulsification time, low dosage and good emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the superparamagnetic iron ferric oxide particle Fe of dendrimer modification 3 o 4 Preparation of @PAMAM

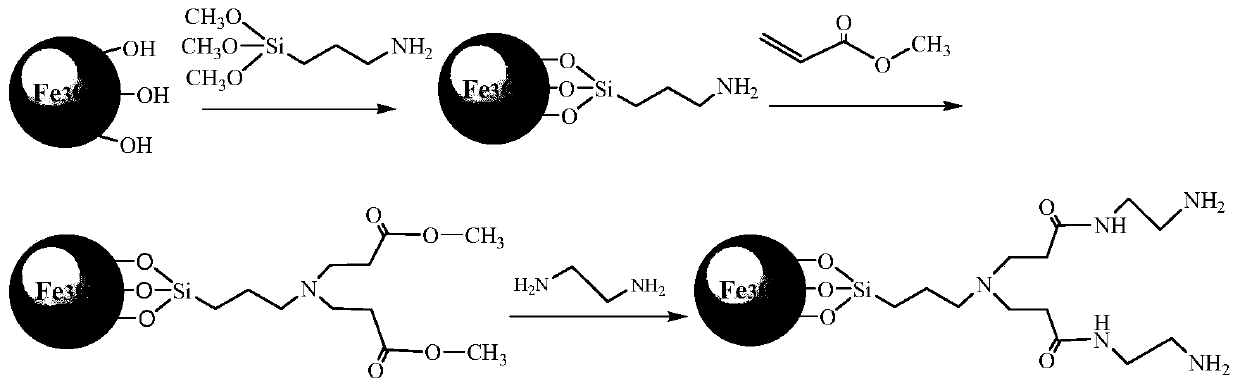

[0051] Fe 3 o 4 The synthesis route of @PAMAM magnetic particles is as follows figure 1 shown.

[0052] The specific method is as follows: in nitrogen atmosphere, 0.01mol Fe 3 o 4Disperse nanoparticles in 100ml ethanol, use 200ml toluene as solvent, add 0.0232mol 3-aminopropyltrimethoxysilane reagent to react at 110℃ for 8h, get black particles, then use anhydrous methanol as solvent, slowly add 0.05mol methyl acrylate Esters were reacted at 35°C for 40h to obtain magnetic particles modified with 0.5GPAMAM dendrimers. Finally, 200ml of anhydrous methanol was used as a solvent, and 0.1mol ethylenediamine was slowly added, and reacted at 45°C for 50h to obtain 1G Fe 3 o 4 @PAMAM magnetic particles.

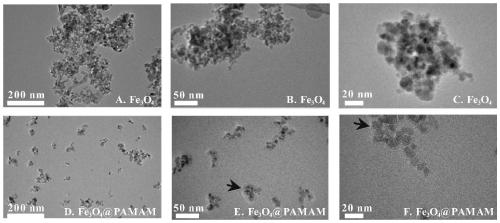

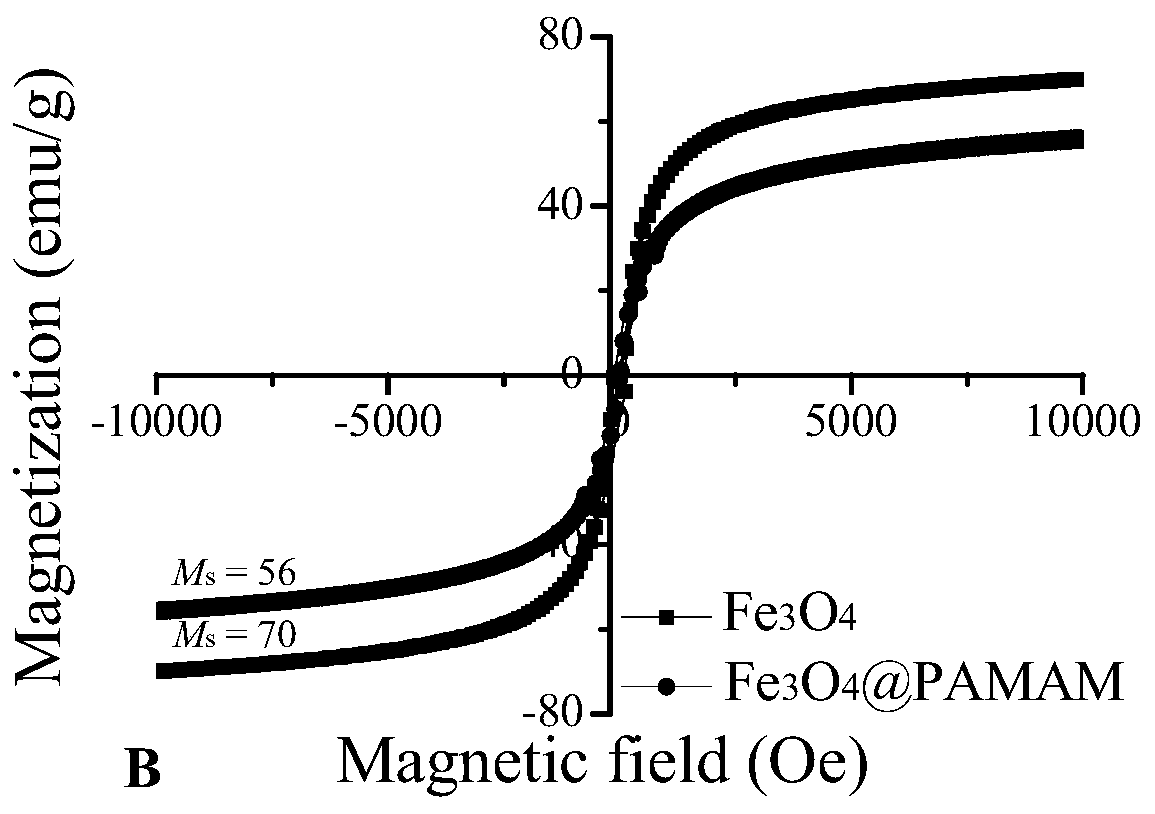

[0053] Superparamagnetic Fe3O4 particles modified by prepared dendrimers Fe 3 o 4 @PAMAM for characterization. Such as figure 2 As shown, Fe...

Embodiment 2

[0055] Embodiment 2, the preparation of the emulsion based on magnetic particles

[0056] Will be dispersed with the Fe that different concentration embodiment 1 prepares 3 o 4 Dodecane (oil phase) of @PAMAM magnetic particles: water is added to the container at a volume ratio of 2:1, and emulsified on a vortex emulsifier at a speed of 2500r / s for 30s to obtain stable Fe 3 o 4 @PAMAM is an emulsion of emulsifiers.

[0057] Such as Figure 4 As shown, with the emulsifier Fe 3 o 4 With an increase in the content of @PAMAM, the volume V of the stable emulsion formed e increase, and this state can be maintained for a long time, and with the emulsifier Fe 3 o 4 As the content of @PAMAM increases, the volume of the stable emulsion accounts for the total system volume V total ratio (V e / V total ) were 80%, 90% and 100% respectively. After standing for a period of time, the emulsion did not change much. Until standing for 25 days, a small amount of demulsification occurred...

Embodiment 3

[0058] Embodiment 3, demulsification of emulsion based on magnetic particles

[0059] With the different concentration Fe that just prepared in embodiment 2 3 o 4 @PAMAM magnetic particle emulsion is placed on a large magnet (0.4T) and stirred at a low speed (stirring speed is 30r / min) for magnetic response demulsification. The demulsification effect is as follows Figure 5 shown. It can be seen that different concentrations of Fe 3 o 4 @PAMAM Magnetic Particle Emulsion has good demulsification effects, achieving complete separation of oil and water, and an obvious oil-water interface can be observed in the liquid. With Fe 3 o 4 As the content of @PAMAM magnetic particles increases, the longer it takes for the emulsion to achieve complete demulsification, the harder it is to break the emulsion. The demulsification time is 1min20s, 8min, and 17min20s respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com