Sodium transition metal oxide of P3 structure and its preparation method and sodium ion battery

A transition metal and oxide technology, applied in the field of sodium transition metal oxide with P3 structure and its preparation, can solve the problems of low energy density of sodium ion battery, unstable air, poor deintercalation ability of sodium ion, etc., and achieve good sodium Ion deintercalation ability, resolving sodium defects, resolving structural instability, and the effect of poor sodium ion deintercalation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Thus, the second aspect of the present invention provides a method for preparing the above-mentioned sodium transition metal oxide of P3 structure, which includes the following steps:

[0046] dissolving nickel salt, manganese salt, and M salt in water to obtain a corresponding mixed transition metal salt solution, and performing coprecipitation reaction on the obtained mixed transition metal salt solution by co-precipitation method to obtain a transition metal carbonate precipitation precursor;

[0047] According to the stoichiometric ratio, the sodium-containing compound and the transition metal carbonate precipitation precursor are mixed and sintered to obtain a sodium transition metal oxide with a P3 structure.

[0048] The preparation method is explained in detail below.

[0049] The nickel salt involved in the raw material can be at least one in nickel sulfate, nickel acetate, nickel nitrate; Described manganese salt is selected from at least one in manganese sulf...

Embodiment 1

[0067] A method for preparing a sodium transition metal oxide of P3 structure, comprising the steps of:

[0068] (a). Mix and dissolve nickel sulfate and manganese sulfate in water at a molar ratio of 1:1, configure a mixed transition metal salt solution of 2mol / L nickel sulfate and manganese sulfate, use 2mol / L sodium carbonate and 0.2mol / L ammonia water mixed aqueous solution is used as a precipitant, and the pH value is controlled to be about 8.0, and the nickel-manganese carbonate precursor is prepared by co-precipitation.

[0069] (b). Mix sodium carbonate with the nickel-manganese carbonate precursor obtained in step (a) according to the molar ratio of 0.45:1, place it in a resistance heating air atmosphere furnace and sinter at a constant temperature of 500°C for 5 hours, then raise the temperature to 800° C. and sintered at a constant temperature for 20 h, and cooled naturally to room temperature to obtain sample 1.

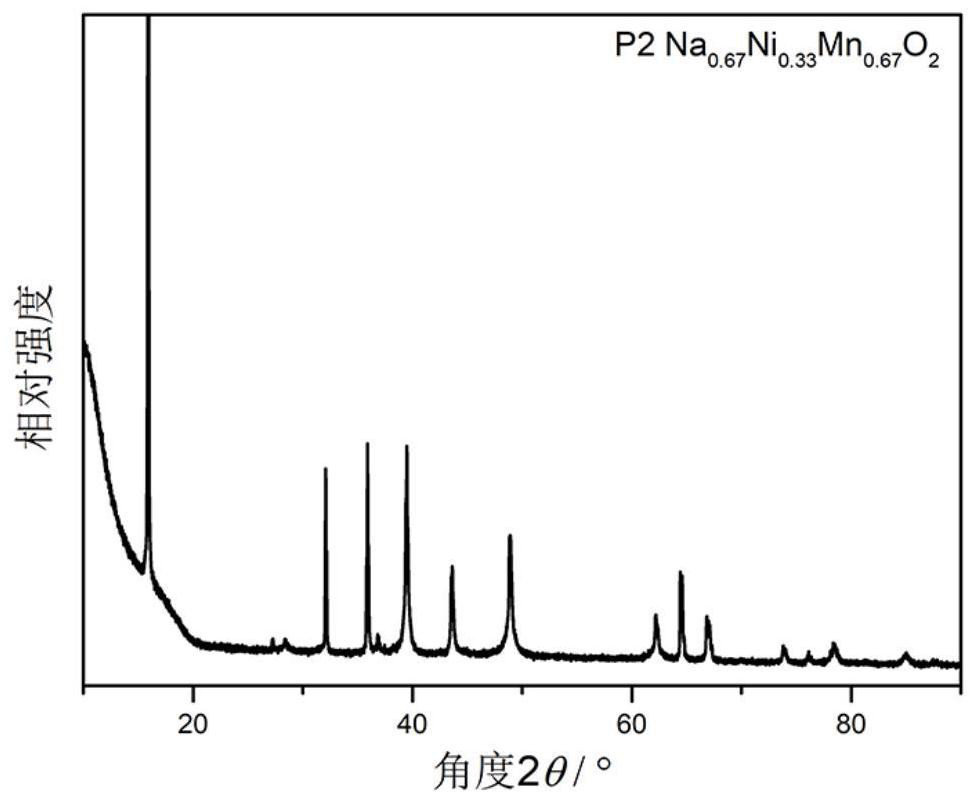

[0070] XRD, ICP and SEM tests were carried out on...

Embodiment 2

[0072] A method for preparing a sodium transition metal oxide of P3 structure, comprising the steps of:

[0073](a). Mix and dissolve nickel sulfate and manganese sulfate in water at a molar ratio of 1:1, configure a mixed transition metal salt solution of 1.5mol / L nickel sulfate and manganese sulfate, use 1.5mol / L sodium carbonate and A mixed aqueous solution of 0.15 mol / L ammonia water was used as a precipitating agent, and the pH value was controlled to be about 8.0, and nickel-manganese carbonate precursor was prepared by co-precipitation.

[0074] (b). Sodium carbonate is mixed with the nickel manganese carbonate precursor obtained in step (a) according to the molar ratio of 0.50:1, and then placed in a resistance heating air atmosphere furnace for constant temperature sintering at 500 ° C for 3 hours, and then the temperature is raised to 750° C. and sintered at a constant temperature for 15 hours, and cooled naturally to room temperature to obtain sample 2.

[0075] XR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com