Surface treatment composition, production method therefor, surface treatment method using surface treatment composition, and production method for semiconductor substrate

A technology of surface treatment and composition, which is applied in the field of surface treatment methods and the manufacture of semiconductor substrates, and can solve problems such as device reliability degradation and bad influence on semiconductor electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0232] [Preparation of Surface Treatment Compositions A-1 to A-4]

[0233] Each surface treatment composition was prepared in the same manner as the preparation of the above-mentioned surface treatment composition a-1, except that the ionic functional group-containing polymer was changed to the type shown below:

[0234] Use in surface treatment composition A-1: sodium salt of acrylic acid-acrylamide tert-butyl sulfonic acid copolymer, weight average molecular weight 10000, ionic functional group (acidic functional group: sulfonic acid (salt) group) density 40%, pKa0 ~1, referred to as copolymer WB in the following Table 1

[0235] Use in surface treatment composition A-2: acrylic acid-acrylamide tert-butyl sulfonic acid copolymer, weight average molecular weight 9000, ionic functional group (acidic functional group: sulfonic acid (salt) group) density 60%, pKa 0~1, Referred to as copolymer WC in Table 1 below

[0236] Use in surface treatment composition A-3: acrylic acid...

Embodiment 5~8

[0242] [Preparation of Surface Treatment Compositions B-1 to B-4]

[0243] Except that polystyrene sulfonic acid (weight average molecular weight 10000, ionic functional group (acidic functional group: sulfonic acid (salt) group) density 100%, pKa=1.0) as the macromolecule containing ionic functional group was made into the following Each surface treatment composition was prepared in the same manner as the preparation of the surface treatment composition b-1 above, except that the addition amount in the composition shown in Table 2 was further added to water (deionized water).

Embodiment 9~12 and 13~15

[0245] [Preparation of Surface Treatment Compositions B-5 to B-8]

[0246] Except that the polyvinyl alcohol as a wetting agent is changed to sulfonic acid (salt) group-containing polyvinyl alcohol (weight-average molecular weight 10000, ionic functional group density 6%, pKa=1.0) as an ionic functional group-containing polymer and set Except the addition amount in the composition shown in following Table 2, each surface treatment composition was prepared similarly to the preparation of the said surface treatment composition B-1.

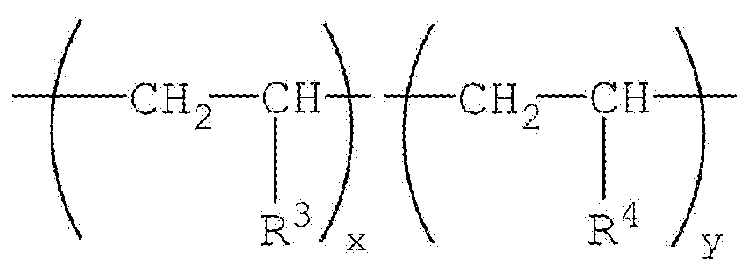

[0247] Here, as the sulfonic acid (salt) group-containing polyvinyl alcohol, a copolymer represented by the following formula including a structural unit having a sulfonic acid (salt) group and a structural unit derived from polyvinyl alcohol as structural units is used. Here, the ratio of the number of structural units derived from monomers having a sulfonic acid (salt) group to the number of structural units derived from all monomers in the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com