Single component moisture curing polyurethane waterproof coating

A polyurethane waterproof, one-component technology, applied in polyurea/polyurethane coatings, coatings, roof insulation materials, etc., to achieve the effect of improved rain resistance and curability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

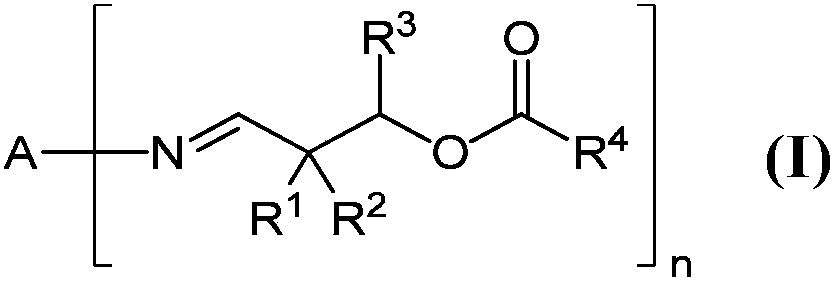

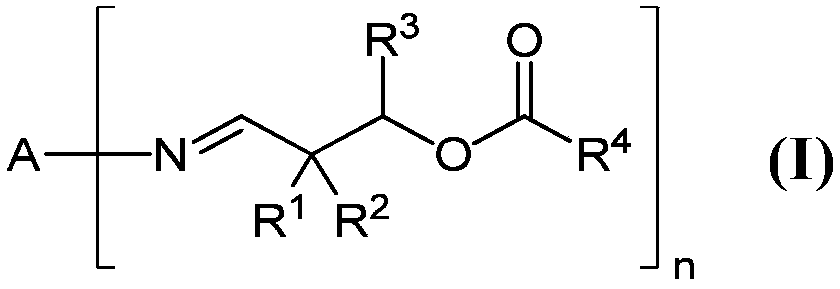

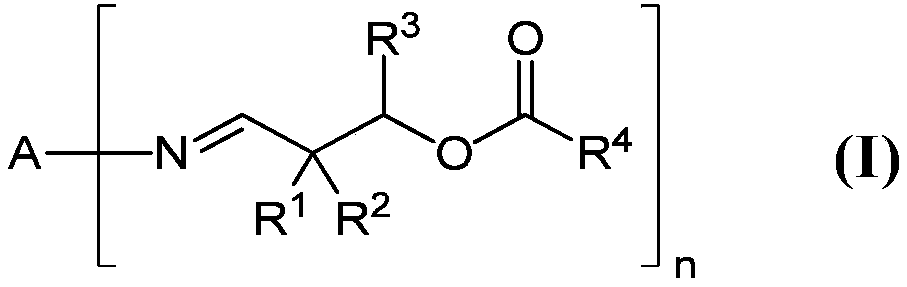

Image

Examples

preparation example Construction

[0034] The method for preparing the polyurethane prepolymer of the present invention comprises optionally in the presence of a catalyst, the polyol component and toluene diisocyanate (TDI) (such as 2,4- or 2,6-toluene diisocyanate or a mixture thereof) reaction. Toluene diisocyanate is known per se to those skilled in the art and is commercially available under various trade names.

[0035] Polyurethane prepolymers can be prepared using one or more polyols. Although the polyols used in polyurethane preparation can theoretically be, for example, polyether polyols, polyester polyols, polycarbonate polyols, castor oil and its derivatives or hydroxyl-functional polybutadienes and mixtures thereof, in In order to realize the above-mentioned performance improvement within the scope of the present invention, especially from the aspects of viscosity and water resistance, the polyol component is basically composed of polyether polyol, more preferably 80% by weight, preferably 90% by w...

Embodiment

[0124] The following examples further illustrate the present application, but it should be clear that the present application is not limited to these examples.

[0125] raw material

[0126]

[0127] Preparation of prepolymer

[0128] Preparation of TDI prepolymer:

[0129] Add 536.1g of trihydric alcohol (molecular weight: 4800) and 340.8g dihydric alcohol (molecular weight: 2000) into the pre-polymerization reaction device, and adjust the temperature of the oil bath to the reaction temperature (50±5)°C. Under the protection of nitrogen, 122.4g of TDI and 0.8g of catalyst were quickly added to the reaction device, and the temperature was raised to (80±5)°C for prepolymerization. During the reaction process, samples were taken to analyze the content of NCO. When the analysis value was basically consistent with the design value, the reaction was terminated, and the product was packed into a sealed container and sealed with nitrogen gas.

[0130] Preparation of MDI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com