Automobile steering piston waste heat normalizing process

A piston and waste heat technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of high production cost, short residence time, and uneven hardness distribution of forgings, and achieve good hardness uniformity, good quality stability, and shortened The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

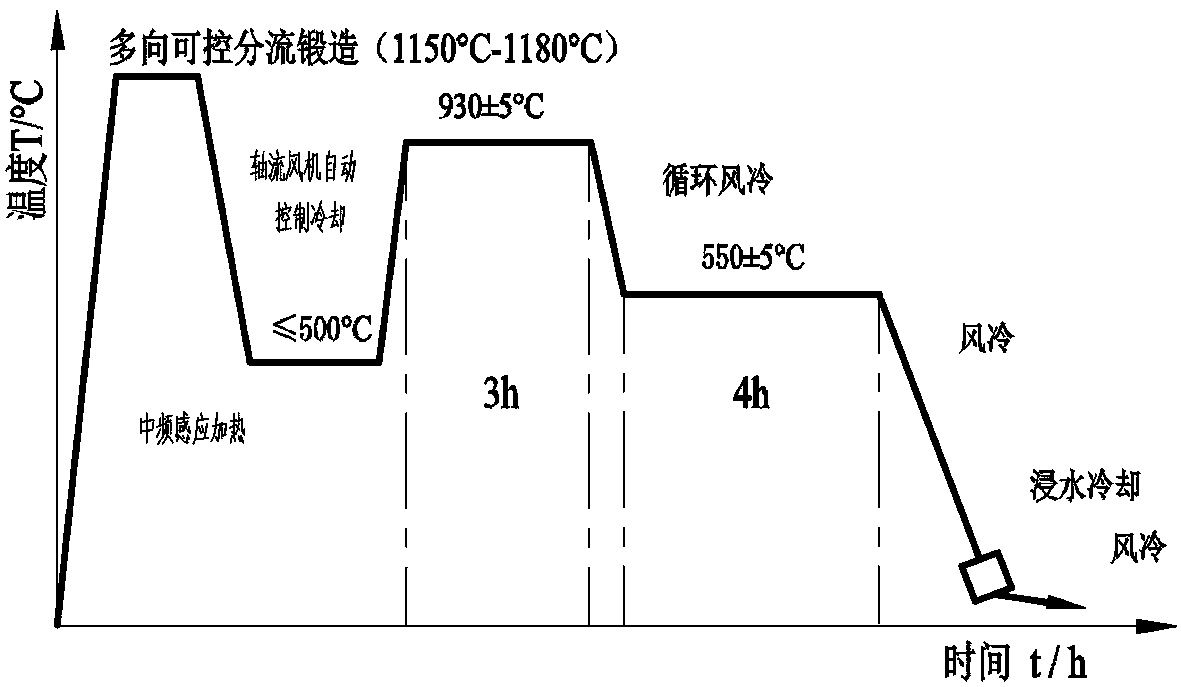

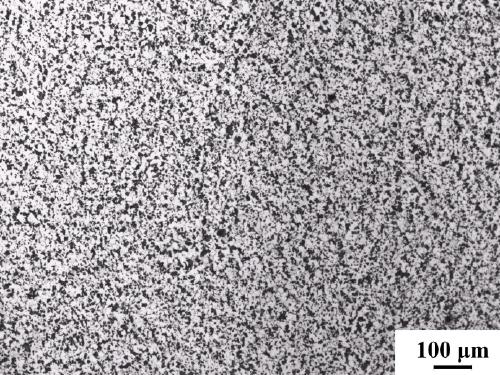

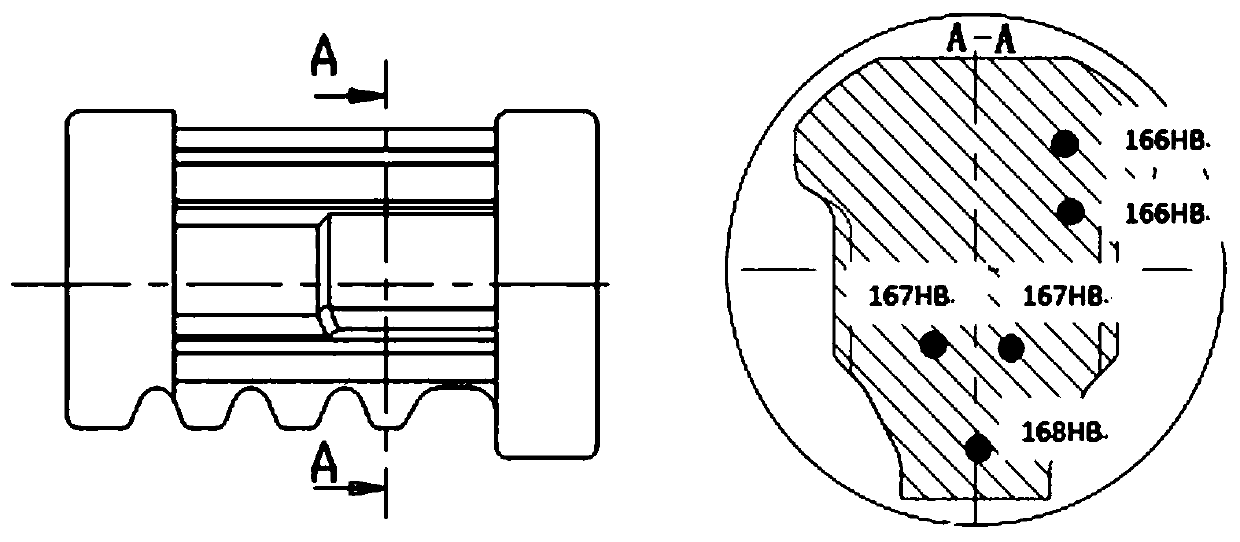

[0027] A kind of automobile steering piston residual heat normalizing process, the forging material is 20CrMnTi, the piston diameter is 100-120mm, comprising the following steps:

[0028] (1) Carry out overall pass-through intermediate frequency induction heating on the bar, control the heating temperature at 1150~1180°C, and heat at a rate of 2°C / s. An overtemperature automatic sorting device is installed at the exit of the intermediate frequency induction furnace;

[0029] (2) After heating, place the bar in a multi-directional press for multi-directional controllable diversion forging. The equipment parameters of the multi-directional press are 10,000KN for the main cylinder, 8,000KN for both side cylinders, 3,000KN for the rear cylinder, and 2,000KN for the ejector cylinder. After the bar arrives at the designated position, the robot grips the bar and places it at the designated position of the multi-directional press mold, and performs five-way extrusion, controllable spli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com