Lithium battery negative electrode and lithium battery

A lithium battery and negative electrode technology, which is applied in the field of lithium battery negative electrodes, can solve the problems of heavy negative electrode mass, complicated preparation methods, and low energy density, and achieve the effects of fewer steps, simple preparation methods, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a lithium battery negative electrode, the negative electrode includes an adjacent porous film layer and a lithium battery negative electrode material layer, relative to a lithium battery negative electrode material layer with a thickness of 100 μm, the thickness of the porous film layer is 10- 200 μm, wherein, the preparation method of the porous film layer includes: molding the porous material powder and the binder, wherein the specific surface area of the porous material powder is 10-3000m 2 / g, the pore volume is 0.01-3cm 3 / g, with a nanopore distribution with a pore size of 1-100 nm.

[0020] The present invention uses porous materials to prepare a porous thin film layer, which is placed between the negative electrode material layer and the diaphragm of the lithium battery. The nanoscale pore structure of the porous material can be used to regulate the diffusion process of lithium ions, so that they can evenly re...

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the specific surface area of the porous material powder is 50-2000m 2 / g, preferably 200-1500m 2 / g, more preferably 300-900m 2 / g.

[0026] According to a preferred embodiment of the present invention, the pore volume of the porous material powder is 1-3 cm 3 / g, preferably 1.2-1.8cm 3 / g.

[0027] According to a preferred embodiment of the present invention, the porous material powder has a nanopore distribution with a pore diameter of 2-50 nm, preferably a nanopore distribution with a pore diameter of 2-20 nm.

[0028] The specific surface area, pore volume and pore diameter of the porous material powder in the present invention can be measured by BET method.

[0029] The particle size of the porous material powder in the present invention may be 10 nm-50 μm, preferably 20 nm-20 μm. The particle size of the porous material powder can be measured by particle size distribution.

[0030] According to...

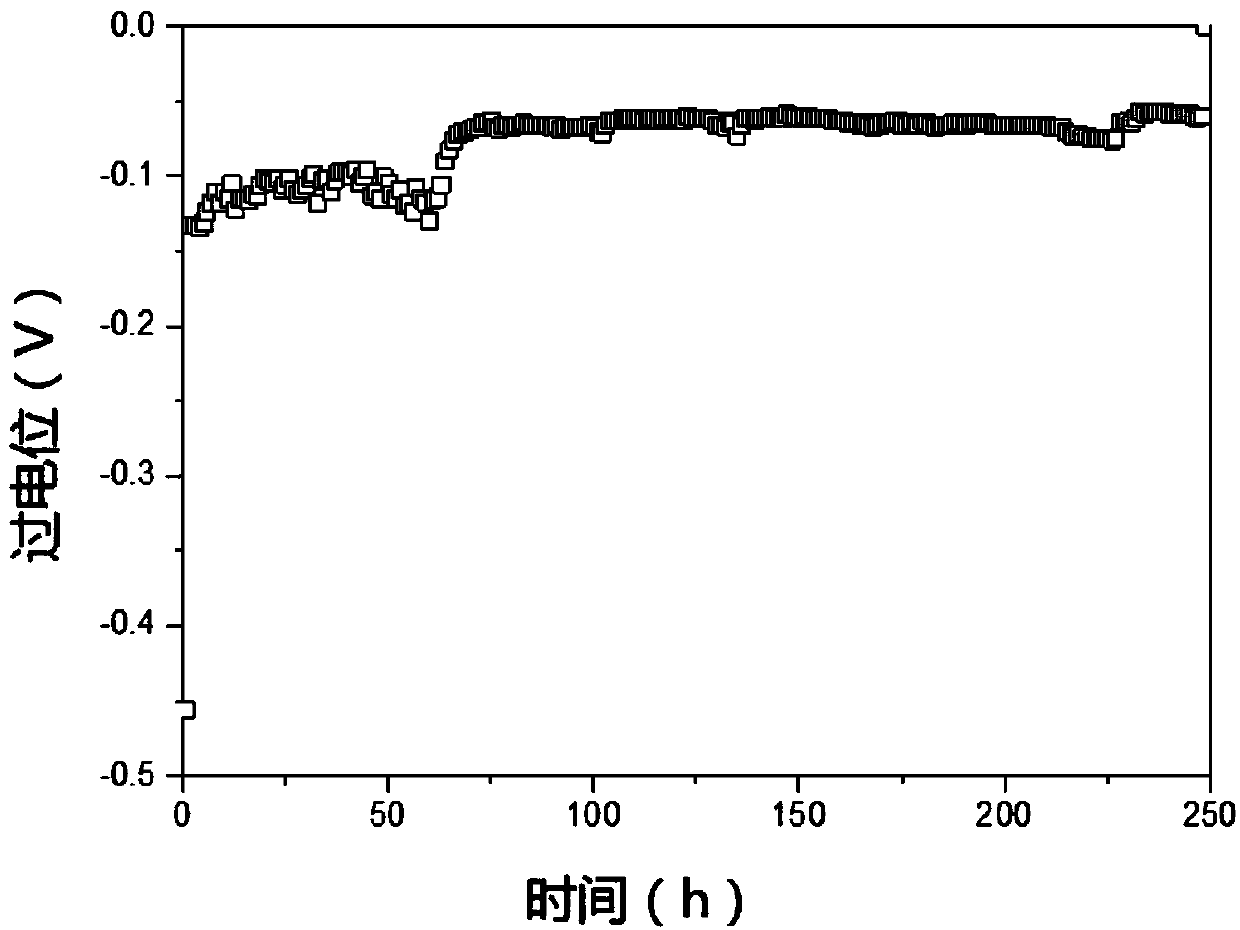

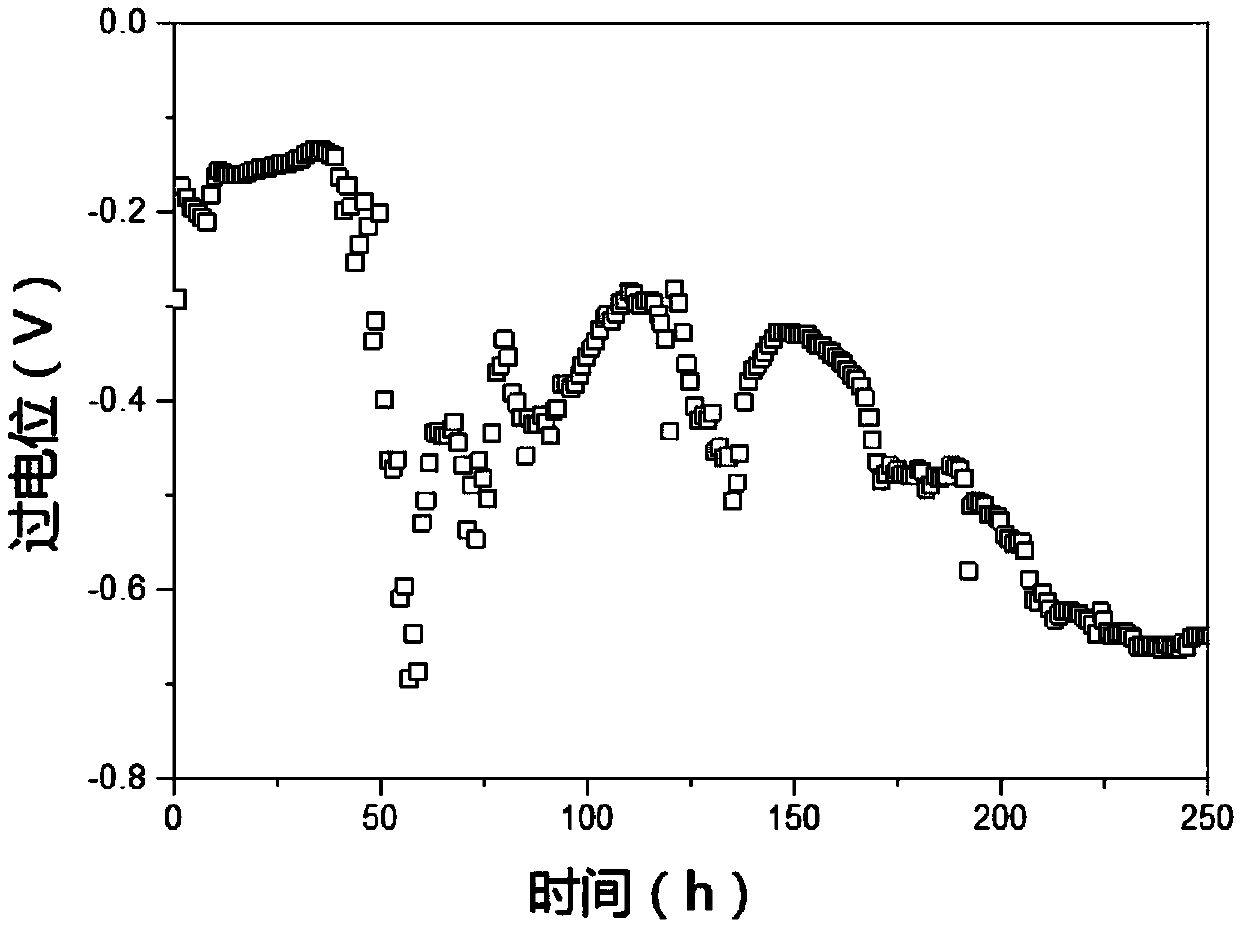

Embodiment 1

[0048] It will have a pore size of 2-5nm and a specific surface area of 900m 2 / g, the pore volume is 1.2cm 3 g, particle size is 5 μ m of activated carbon (commercially purchased from Nanjing Xianfeng Nano Co., Ltd., the brand is the product of CMK-3), the mass fraction is 60% polytetrafluoroethylene emulsion (PTFE, commercially purchased from Sigma company) and water Mixing, the mass ratio of activated carbon to PTFE is 9:1, and the mass ratio of water: (activated carbon + PTFE) is 20:1. The first film with a thickness of 50 μm was rolled on a rolling machine; the first film was dried at 100° C. for 12 hours, and then stamped to obtain a porous film (with a thickness of 40 μm). The porous film is used as the porous film layer, placed between the lithium sheet (thickness: 100 μm) and the separator (Celgard2325) as the negative electrode material layer of the lithium battery, and the positive electrode is the lithium sheet; with 1M LiPF 6 The EC / DEC solution is used as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com